SX-SW100

4

12

34

12

3

4

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 4

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR................................................................................................................................................. 8

2.3 DISPLAY UNIT ......................................................................................................................................... 10

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................12

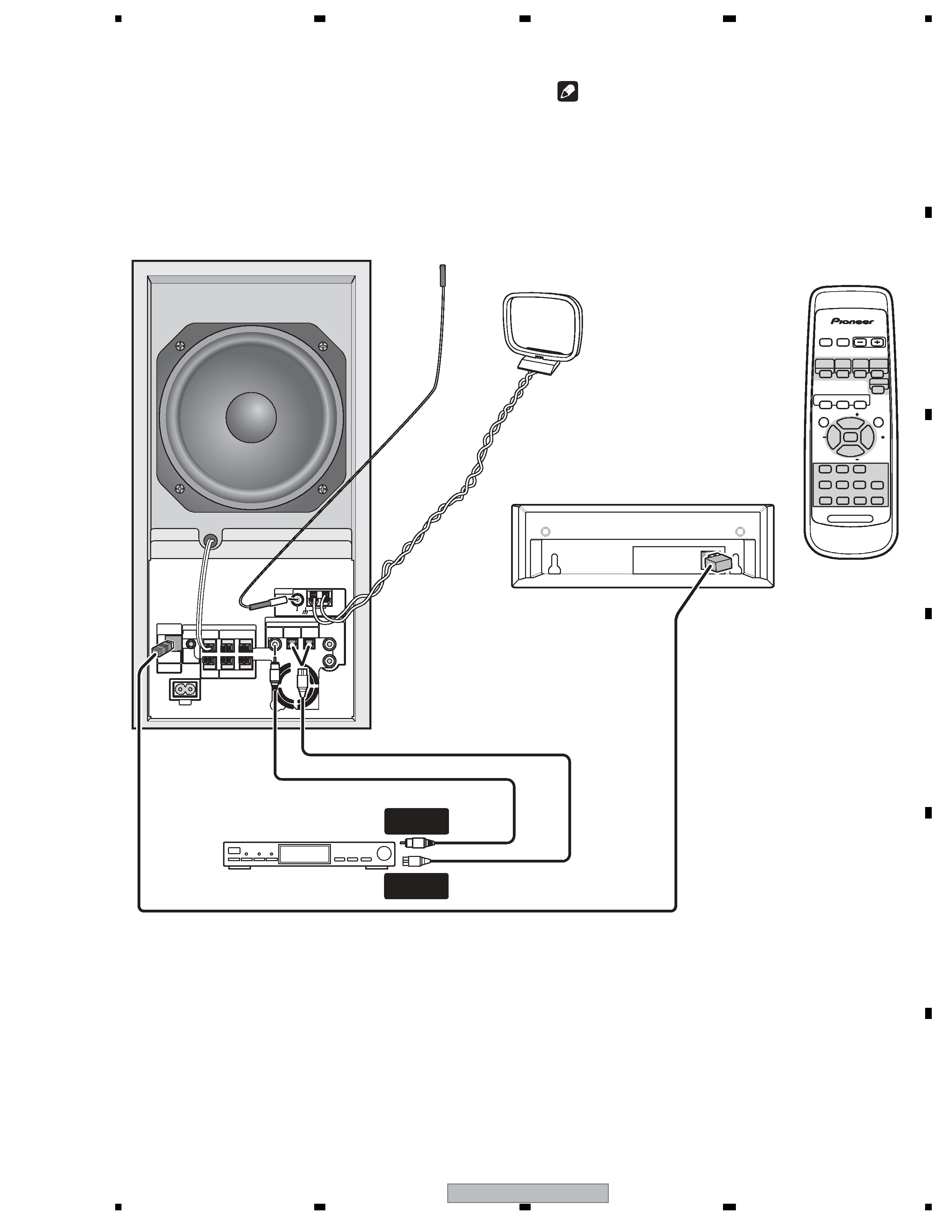

3.1 OVERALL WIRING CONNECTION DIAGRAM AND BLOCK DIAGRAM ................................................ 12

3.2 MAIN ASSY (1/5) ..................................................................................................................................... 14

3.3 MAIN ASSY (2/5) ..................................................................................................................................... 16

3.4 MAIN ASSY (3/5) ..................................................................................................................................... 18

3.5 MAIN ASSY (4/5) ..................................................................................................................................... 20

3.6 MAIN ASSY (5/5) ..................................................................................................................................... 22

3.7 AC INLET, CONNECT and FL ASSYS .................................................................................................... 24

3.8 POWER SUPPLY UNIT............................................................................................................................ 26

3.9 WAVEFORMS .......................................................................................................................................... 28

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 29

4.1 MAIN ASSY ............................................................................................................................................. 30

4.2 AC INLET and CONNECT ASSYS .......................................................................................................... 34

4.3 FL ASSY .................................................................................................................................................. 35

4.4 POWER SUPPLY UNIT............................................................................................................................ 36

5. PCB PARTS LIST ........................................................................................................................................... 38

6. ADJUSTMENT ............................................................................................................................................... 44

7. GENERAL INFORMATION ............................................................................................................................. 45

7.1 DIAGNOSIS ............................................................................................................................................. 45

7.1.1 TEST MODE ...................................................................................................................................... 45

7.1.2 SPECIFICATIONS OF SPEAKER SETUP ........................................................................................ 47

7.1.3 PROPOSAL OF DSP ERROR DISPLAY........................................................................................... 48

7.1.4 CIRCUIT DESCRIPTION OF DIGITAL AMP. SECTION .................................................................... 49

7.1.5 SPECIFICATIONS FOR THE PROTECTION CIRCUITS FOR THE DIGITAL AMPLIFIER ............... 50

7.1.6 CONDITIONS FOR SWITCHING THE ROTATION SPEED OF THE FAN ........................................ 51

7.1.7 DISASSEMBLY.................................................................................................................................. 52

7.2 IC ............................................................................................................................................................. 55

8. PANEL FACILITIES ........................................................................................................................................ 71

1. SPECIFICATIONS

SX-SW100

·

Amplifier section

RMS Power Output :

Front, Center, Surround . . . . . . . . . . . .110 W per channel

(1 kHz, 10 % T.H.D., 3

)

Subwoofer . . . . . . . . . . . 70 W (200 Hz, 10 % T.H.D., 3

)

Front, Center, Surround. . . . . . . . . . . . . 60 W per channel

(1 kHz, 10 % T.H.D., 6

)

Subwoofer. . . . . . . . . . . 60 W (200 Hz, 10 % T.H.D., 6

)

·

FM tuner section

Frequency range. . . . . . . . . . . . . . . . . 87.5 MHz to 108 MHz

Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . 75

, unbalanced

·

AM tuner section

Frequency range

With 9kHz step . . . . . . . . . . . . . . . . 531 kHz to 1,602 kHz

With 10kHz step . . . . . . . . . . . . . . . 530 kHz to 1,700 kHz

Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Loop antenna

·

Miscellaneous

Power requirements. . . . . . . . . . . . AC 110-240 V, 50/60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 W

Power consumption in standby . . . . . . . . . . . . . . . . . . 0.4 W

Dimensions . . . . . . . . . . . . 200 (W) x 375 (H) x 437 (D) mm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 kg

·

Accessories

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

AA/R6 dry cell batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Display cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Optical cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Coaxial cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AM loop antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

FM wire antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Operating instructions