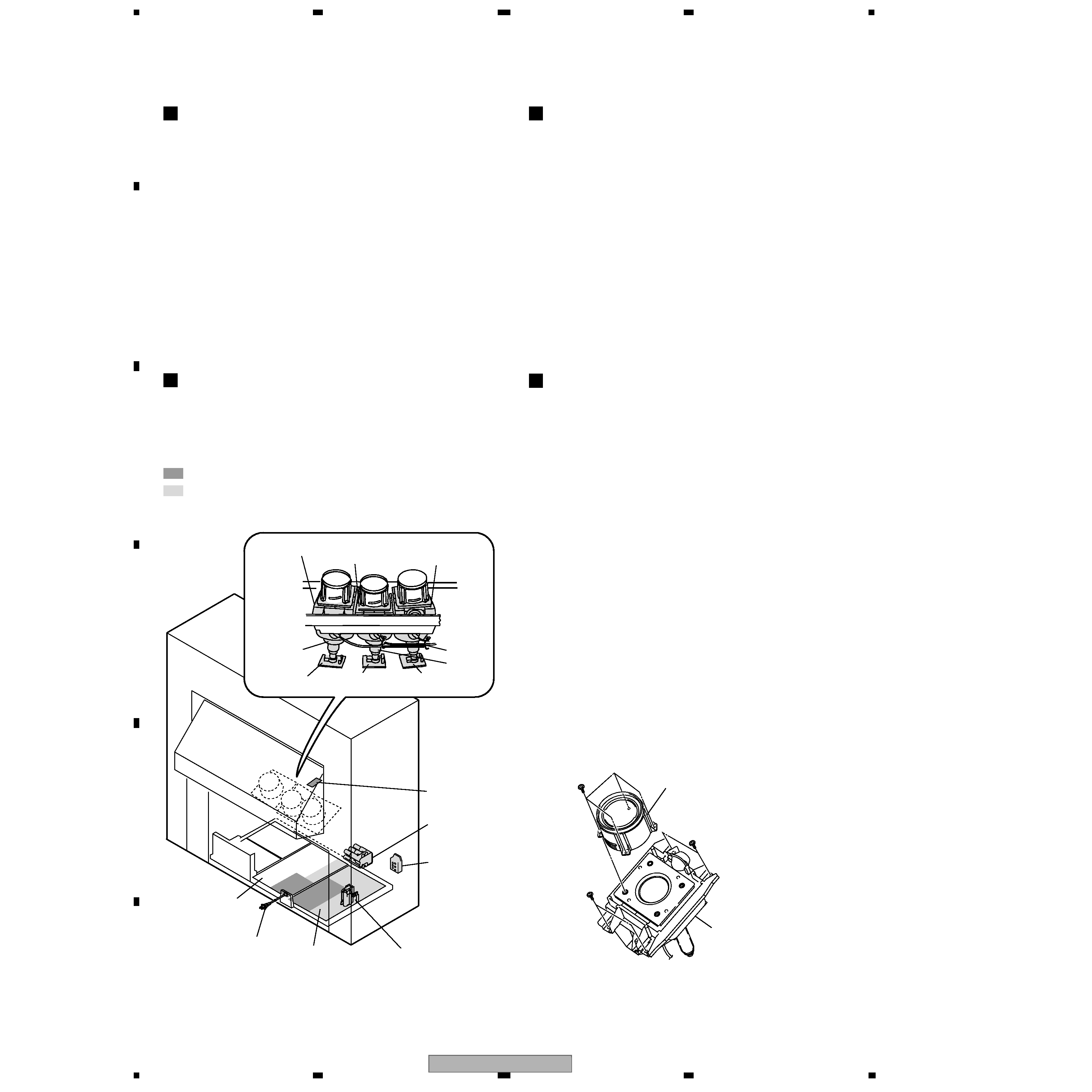

PRO-730HDI

3

5

678

56

7

8

C

D

F

A

B

E

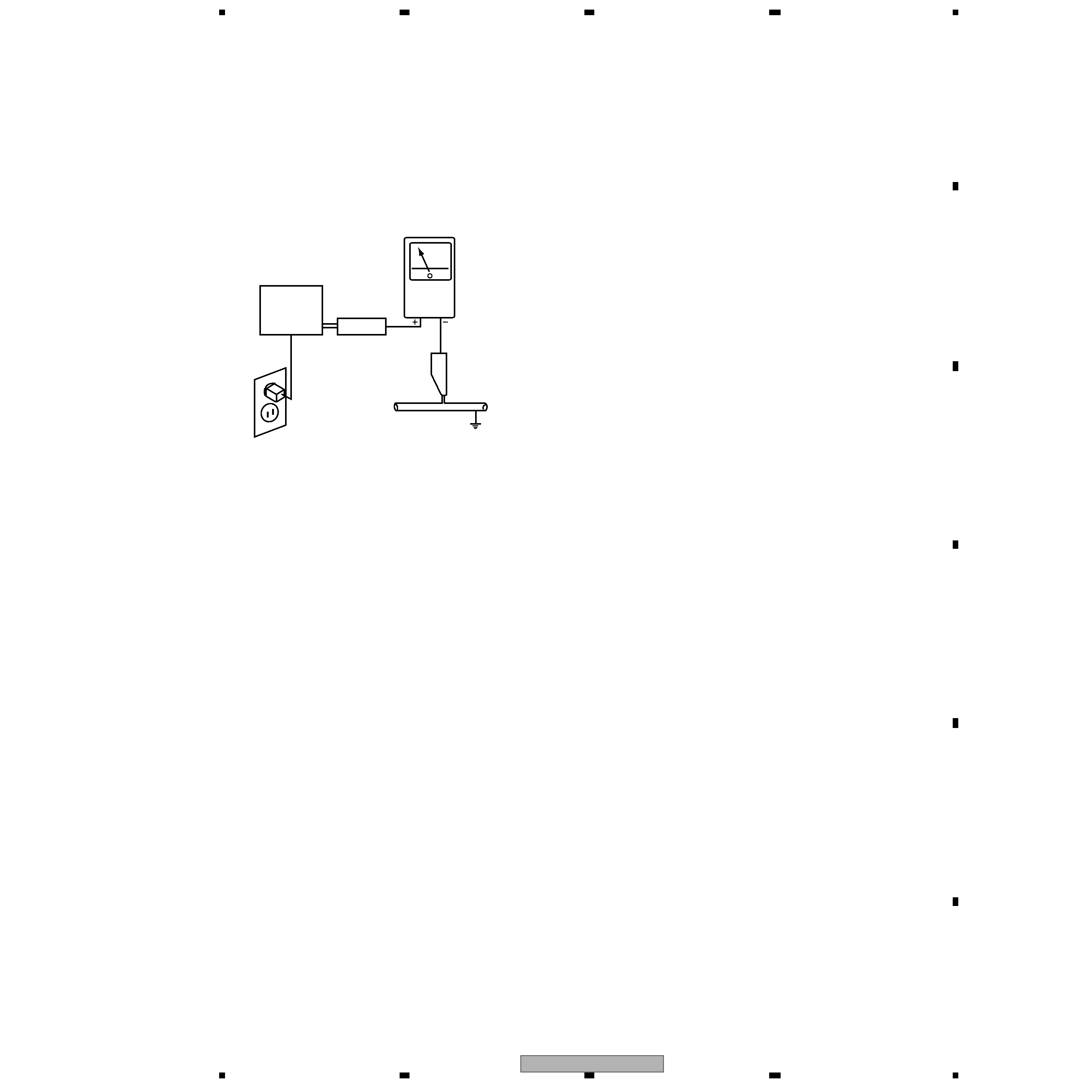

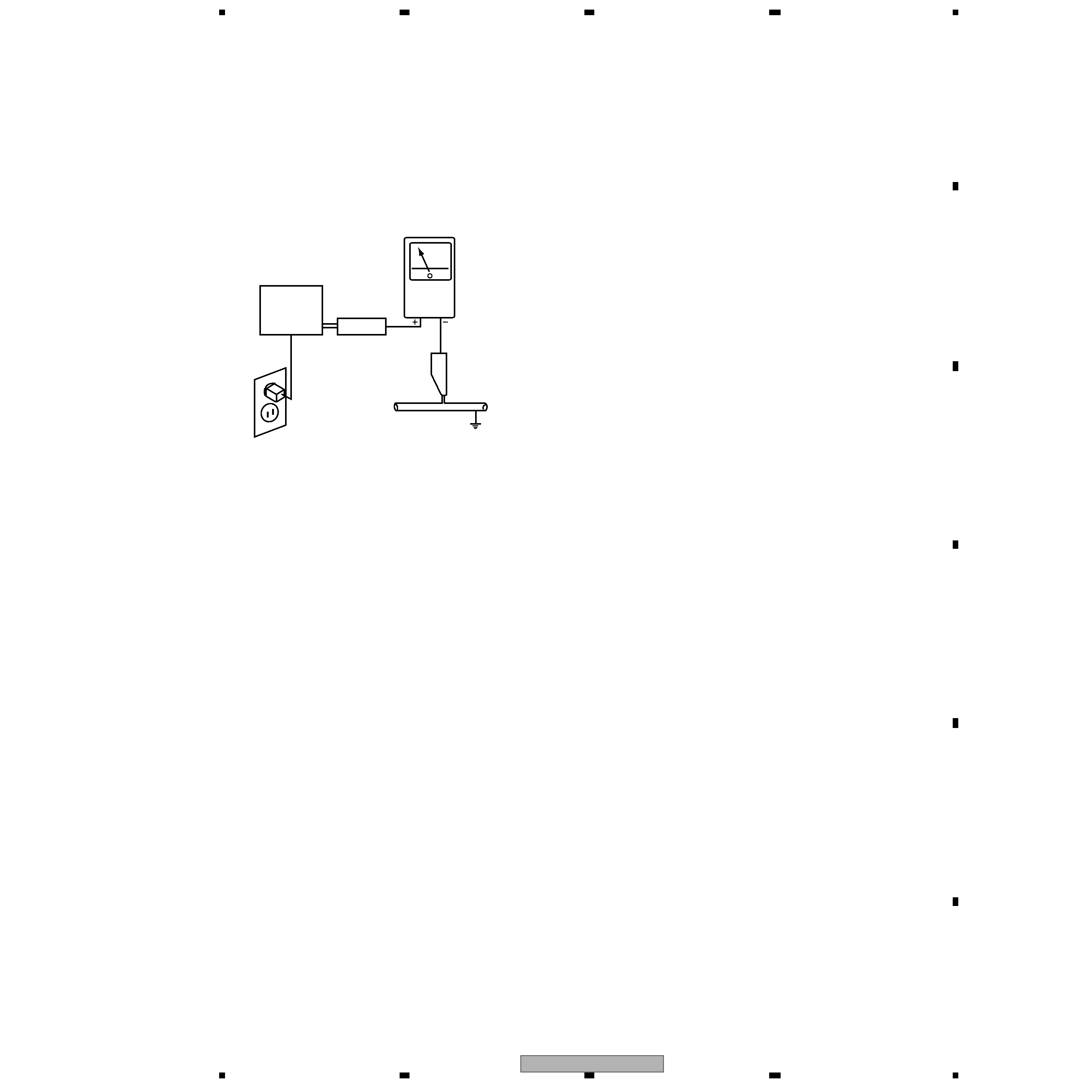

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

Leakage Current Hot Check

Plug the AC line cord directly into a 120V AC 60Hz outlet (do not

use an isolation transformer for this check). Turn the AC power

switch on.

Using a "Leakage Current Tester (Simpson Model 229 equivalent)",

measure for current from all exposed metal parts of the cabinet

(input/output terminals, screwheads, metal overlays, control shaft,

etc.), particularly any exposed metal part having a return path to

the chassis, to a known earth ground (water pipe, conduit, etc.).

Any current measured must not exceed 0.5mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

High Voltage

This set is provided with a X-ray protection for clearly indicating

that voltage has increased in excess of a predetermined value.

Comply with all notes described in this Service Manual regarding

this hold down circuit when servicing, so that this X-ray protection

may correctly be operated.

Serviceman Warning

In the status of the black picture (video muting is being applied)

when no signal is input, high voltage of this set during operation is

less than 30.5kV. In case any component having some relation to

the high voltage is replaced, confirm that the high voltage is lower

than 30.5kV in the status of the black picture when no signal is

input.

To measure H. V. use a high impedance H. V. meter.

Connect () to earth and (+) to the FBT anode cable connector.

(Refer to section "7.1.2 DISASSEMBLY".)

X-radiation

TUBE : The primary source of X-radiation in this set is the picture

tube.

For continued X-radiation protection, the replacement tube must be

the same type as the original, PIONEER approved type.

The picture tube (CRT Service Assy R, G, B) used in this set holds

complete guarantee against X-ray radiation when the X-ray is

sealed (next page ). Accordingly, when the current in flowing to the

picture tube (CRT Service Assy R, G, B), be sure to perform it by

putting the tube into X-ray sealed applied state. Avoid absolutely to

flow the current to the picture tube (CRT Service Assy R, G, B)

itself. Moreover, when the voltage of the high voltage circuit

becomes abnormally a little higher, the picture tube radiates X-rays.

Accordingly, when servicing the high voltage circuit be sure to

replace as an assy with the POWER SUPPLY Assy in the manner

in which has been adjusted to perform normal operation.

Many electrical and mechanical parts in PIONEER set have special

safety related characteristics. These are often not evident from

visual inspection nor the protection afforded by them necessarily

can be obtained by using replacement components rated for higher

voltage, wattage, etc. Replacement parts which have these special

safety characteristics are identified in this Service Manual.

Electrical components having such features are identified by

marking with a > on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire, X-radiation, or other

hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to, or

additional copies of, PIONEER Service Manual may be obtained at

a nominal charge from PIONEER.

1.2 PRODUCT SAFETY NOTICE