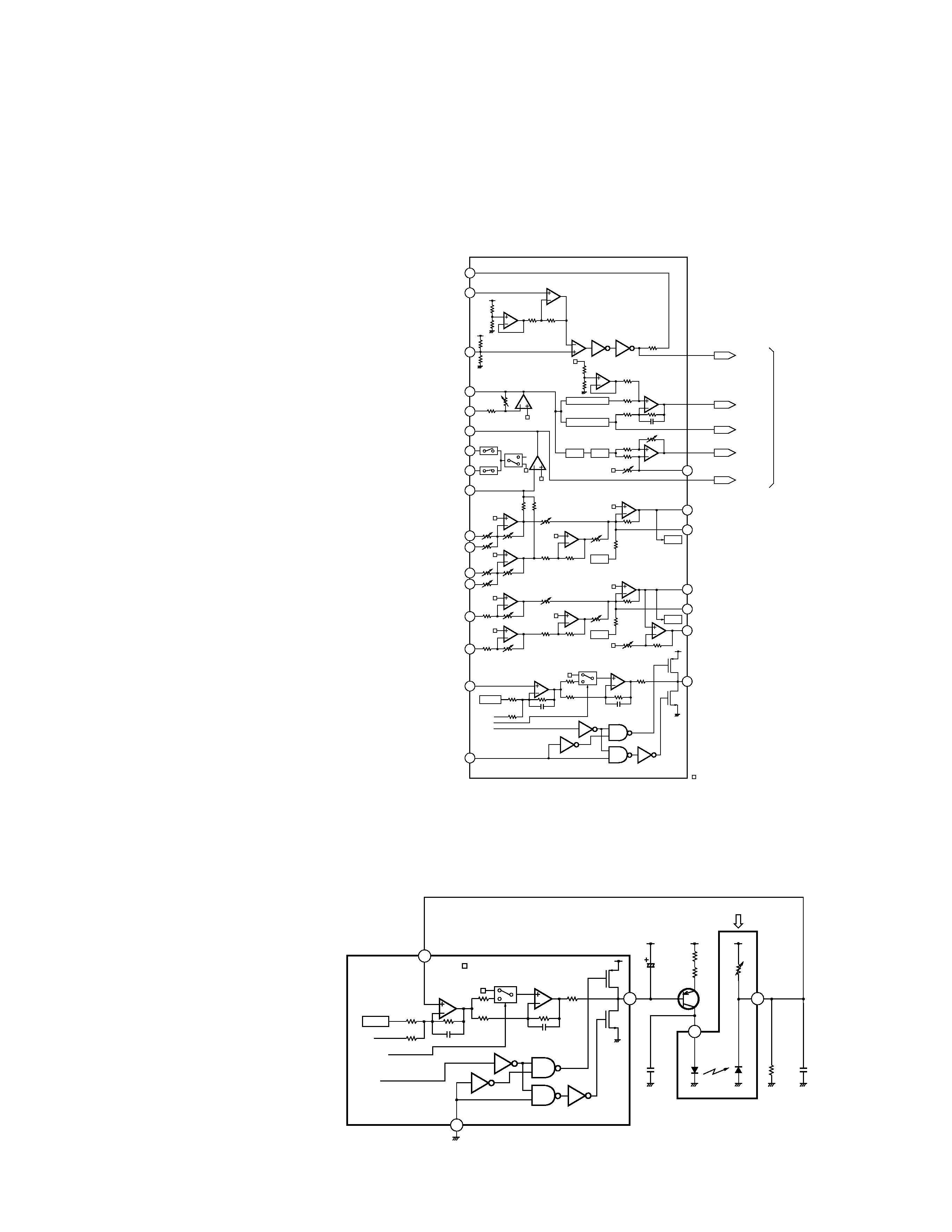

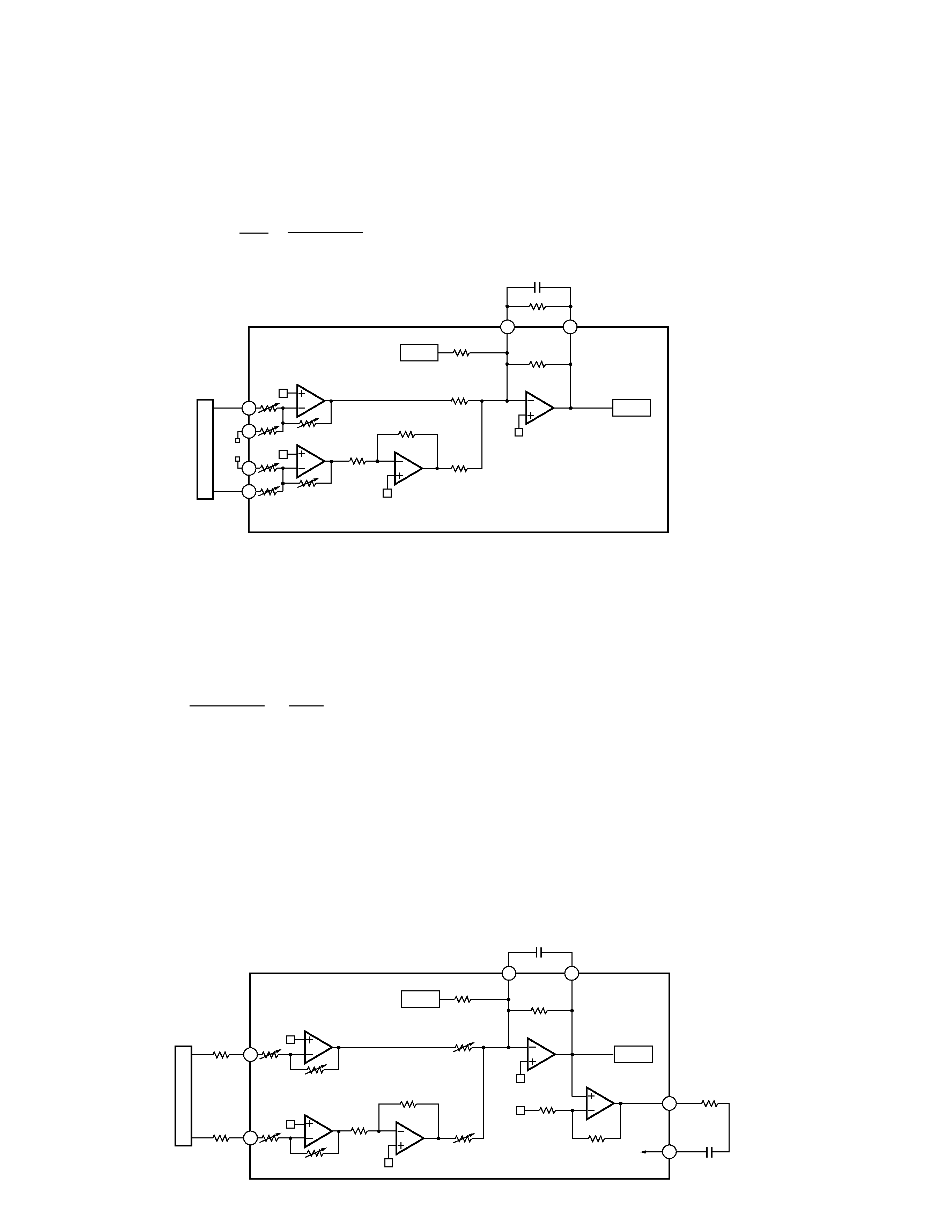

5) Tracking Error Amplifier

The photo-detector outputs E and F are passed through

a differential amplifier and an error amplifier, and then

(E

- F) is output from Pin 93 as the TE signal. The TE

voltage low frequency component is :

TE

= (E - F) ××

= (E - F) × 5.7 (Effective LSI output is 5.0).

Using REFO as the reference, the TE waveform of

approximately 1.3 Vpp is obtained for the TE output.

The final-stage amplifier cutoff frequency is 20 kHz.

6) Tracking Zero Crossing Amplifier

TEC signal (the tracking zero crossing signal) is

obtained by multiplying the TE signal four times. It is

used for locating the zero crossing points of the

tracking error. The zero cross point detection is done for

the following two reasons :

1 To count tracks for carriage moves and track jumps.

2 To detect the direction in which the lens is moving

when the tracking is closed (it is used on the

tracking brake circuit to be described later).

The TEC signal frequency range is 300 Hz to 20 kHz.

TEC voltage

= TE level × 4

Theoretical TEC level is 5.2V. The signal exceeds D-

range of the operational amplifier and thus is clipped.

It, however, can be ignored since this signal is used by

the servo LSI only at the zero crossing point.

4

CX-938

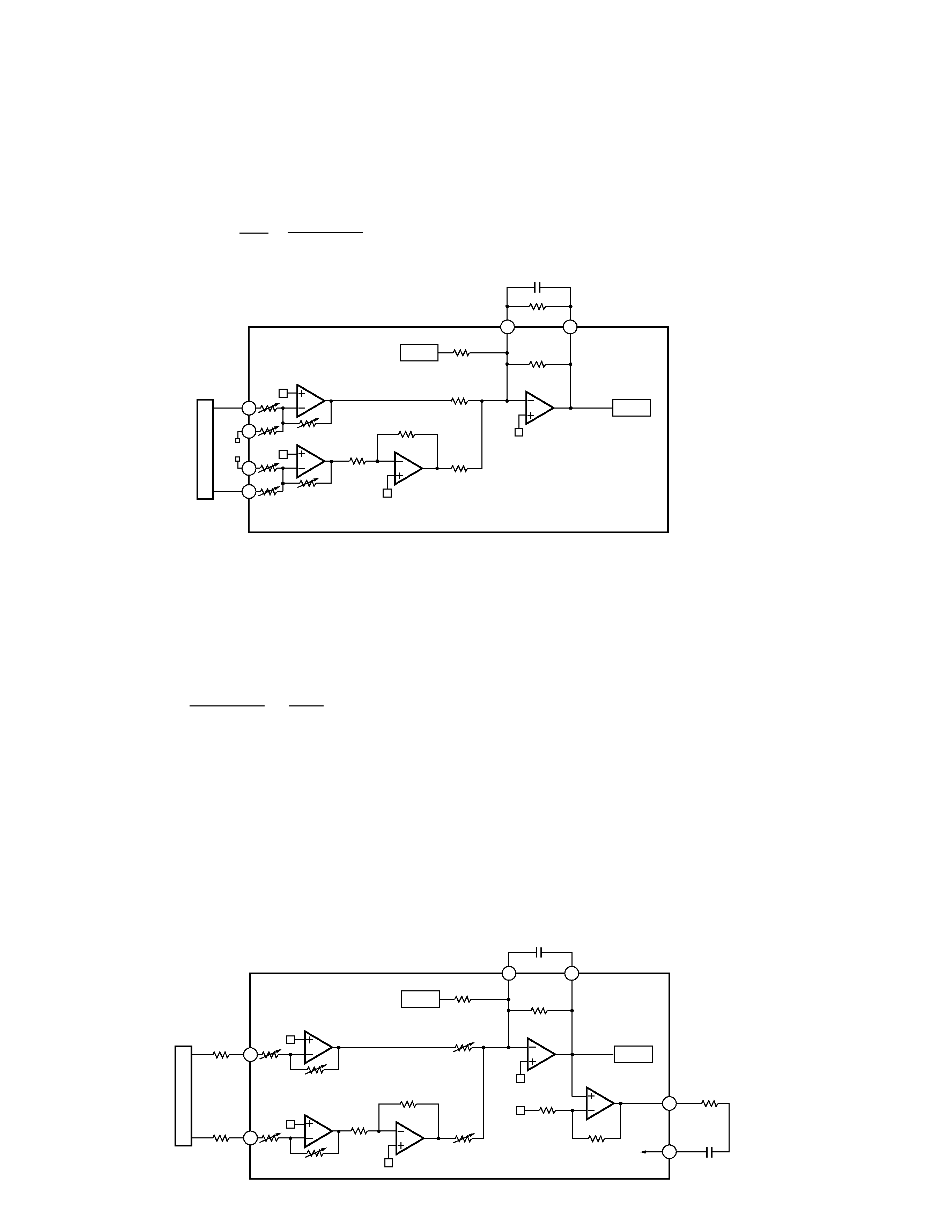

Fig.5 TRACKING ERROR AMPLIFIER AND TRACKING ZERO CROSSING AMPLIFIER

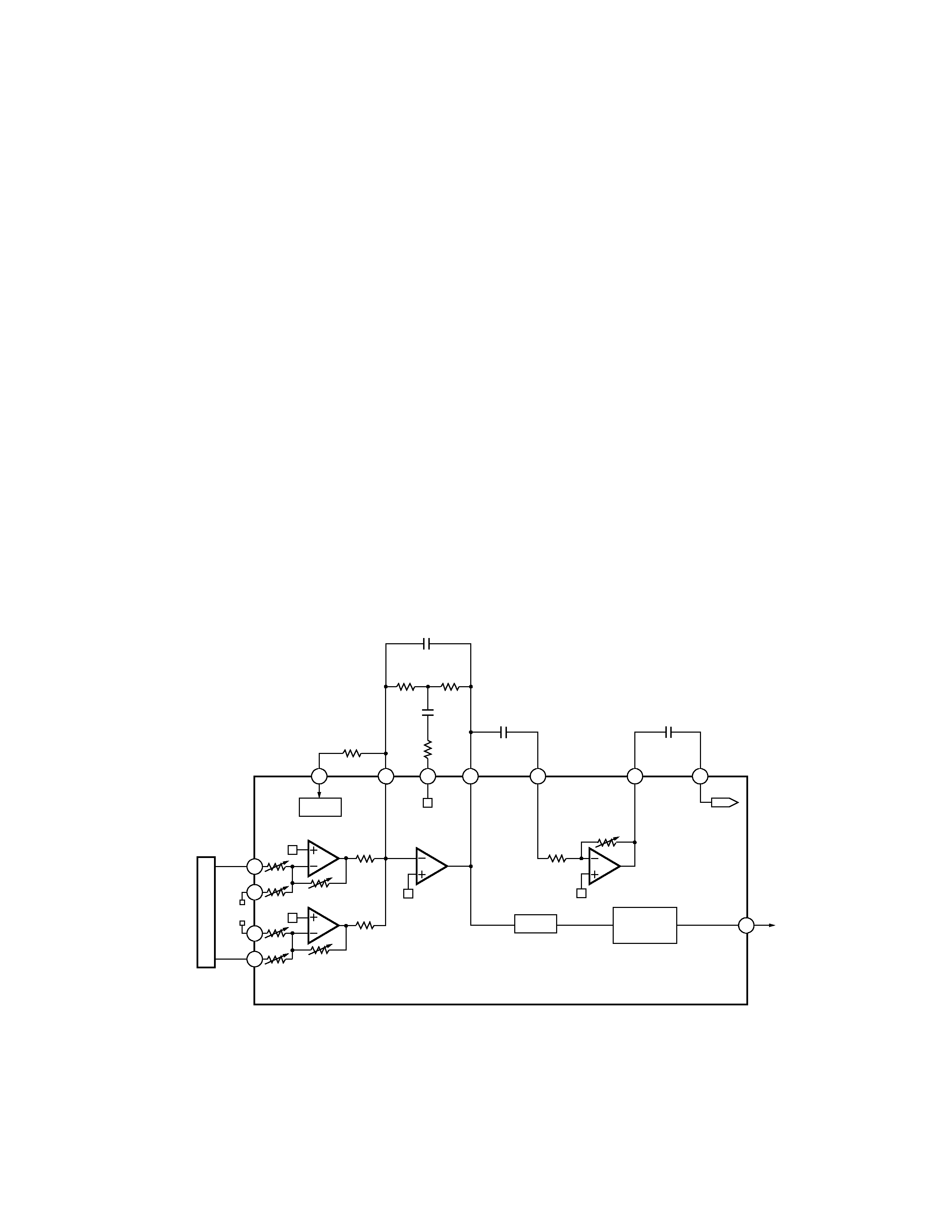

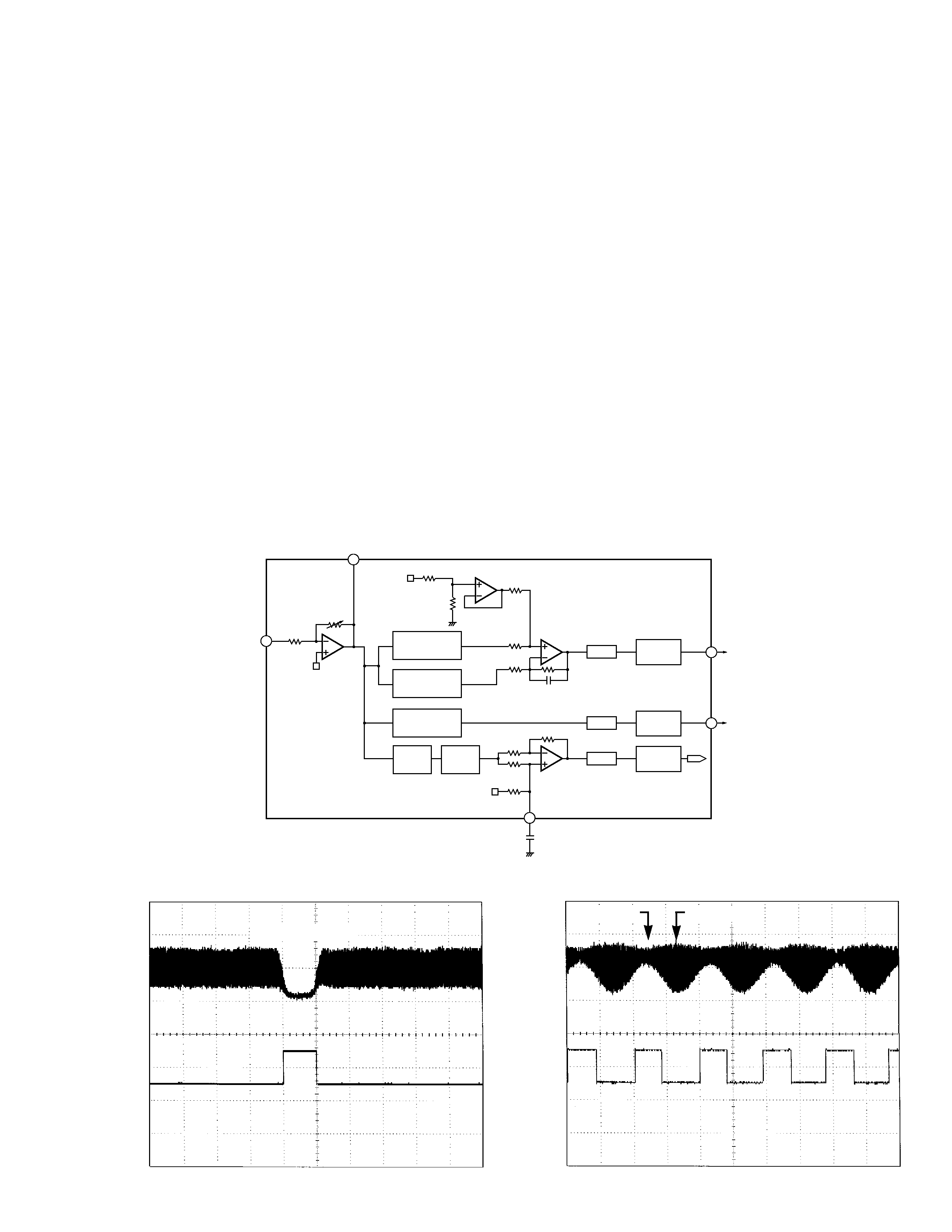

4) Focus Error Amplifier

The photo-detector outputs (A

+ C) and (B + D) are passed

through a differential amplifier and an error amplifier, and

then (A

+ C - B - D) is output from Pin 91 as the FE signal.

The FE voltage low frequency component is :

FE

= (A + C - B - D) ××

= (A + C - B - D) × 5

Using REFO as the reference, an S-curve of approximately 1.5

Vpp is obtained for the FE output. The final-stage amplifier

cutoff frequency is 11.4 kHz.

20k

CN101

84

18

25

83

82

10k

20k

85

A+C

16k

B+D

48k

16k

10k

91

90

D/A

80k

110k

FE

C210 220pF

R208 300k

A/D

FE OFFSET

TO DIG. EQ

48k

38k

CN101

21

23

86

56k

38k

87

F

E

F

224k

E

48k

224k

56k

93

92

D/A

80k

110k

TE

C211 100pF

A/D

TE OFFSET

TO DIG. EQ

48k

R216

27k

R215

27k

60k

20k

95

94

TE2

TEC

R212

0

C212

6800pF

16k

10k

(80k//300k)

20k

Fig.4 : FOCUS ERROR AMPLIFIER

224k

(56k

+27k)

80k

38k