4

MITSUBISHI HS-S5600E

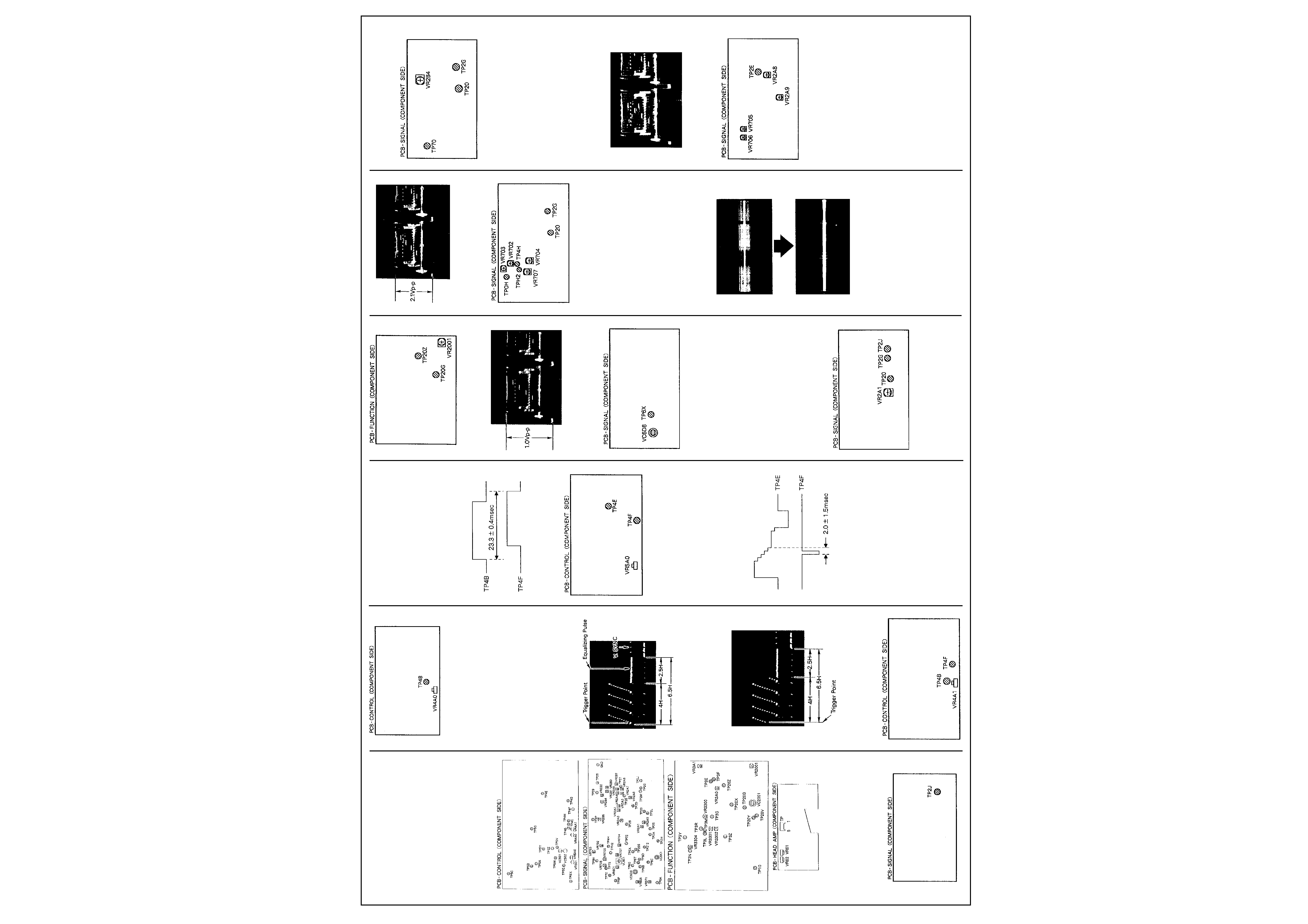

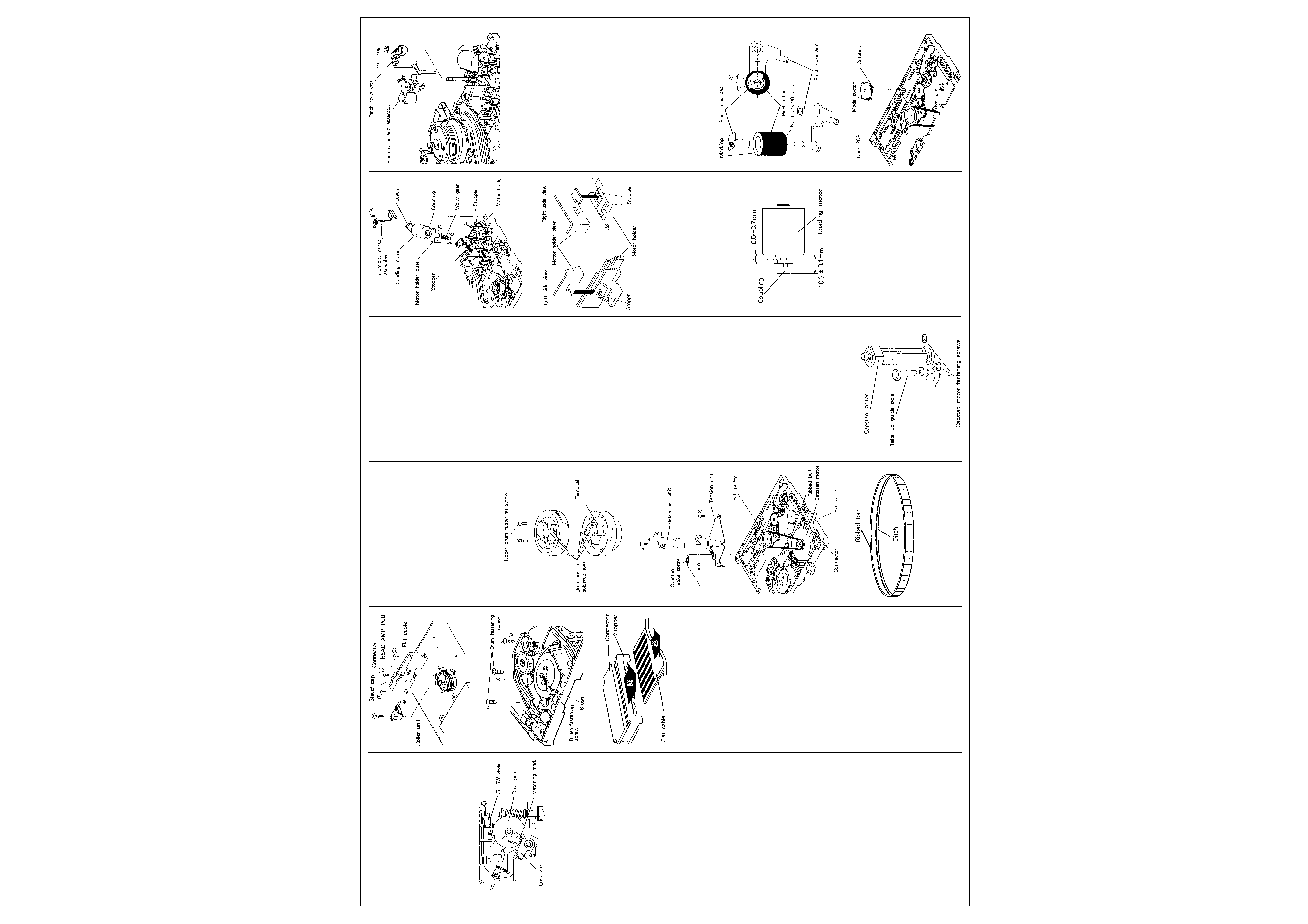

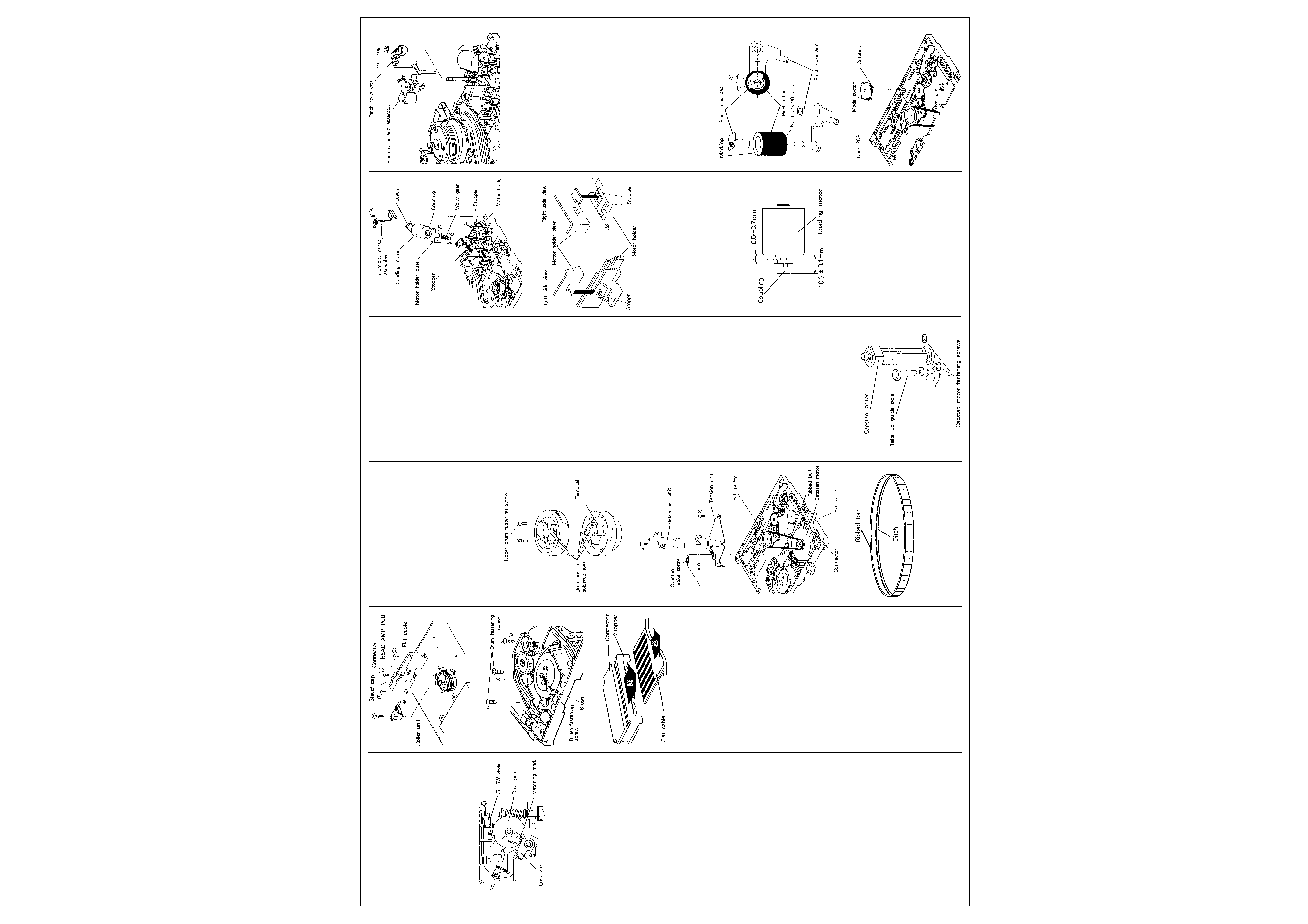

2-2-2 Installation (Refer to Fig. 2-1-3~2-2.)

A.Install the drive gear on the shaft as shown in

Fig. 2-2.

B.Line the matching mark on the drive gear and

beginning of gear section on the lock arm as

shown in Fig.2-2, and install the lock arm.

C.Install the side plate TU to the cassette

housing, and secure it with four snaps (a), (b)

(c) and (d) as shown in Fig. 2-1-3 (see

previous page).

Fig. 2-2

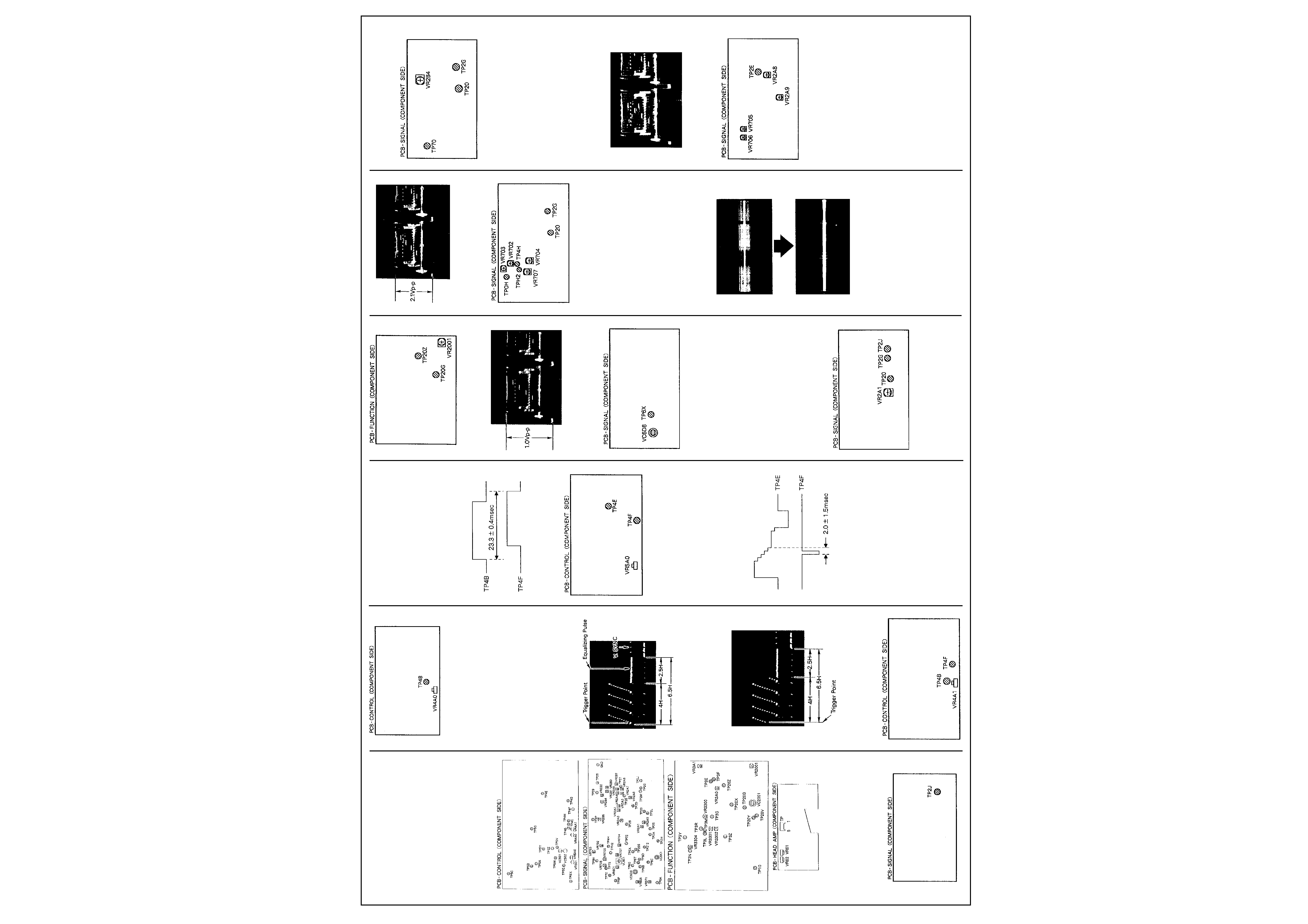

2-3 Drum Assembly

2-3-1 Removal (Refer to Fig. 2-3-1~2-3-3)

A.Disconnect the roller units connector (CP)

from the control PCB.

B. Unscrew the roller unit fastening screw (a)

and remove the roller unit.

C. Unscrew three fastening screws (b), (c) and

(d) and remove the head amplifier PCB which

is connected to the drum assembly.

D.Unscrew the brush fastening screw and

remove the brush as shown in Fig. 2-3-2.

Note: The cable and connector between the

drum and head amplifier may be damaged if

the cable is pulled strongly, as the cable is

short. Remove the shield cap of the PCB,

raise the PCB slightly and disconnect the flat

cable. Removal method for the flat cable

connector and stopper is shown in Fig. 2-3-3.)

Disconnect the grounding wire and remove

the head amplifier PCB.

E.Unscrew three drum fastening screws (e), (f)

and (g) from the reverse side of the deck.

F. Remove the drum assembly by raising it with

care not to touch other parts around the drum

assembly.

G.Disconnect the connectors from the drum

assembly.

2-3-2 Installation (Refer to Fig. 2-3-1, 2-3-2.)

A.Connect the connectors to a new drum

assembly.

B.Place the new drum assembly on the main

plate of the deck slowly being careful not to

touch other parts.

C.Fasten the drum assembly with three

fastening screws (e), (f) and (g) on the

reverse side of the deck.

D.Fasten the brush with the fastening screw.

E.Connect the head amplifier PCB to the drum

assembly and fasten the PCB with three

screws (b), (c) and (d).

F. Connect the roller unit s connector (CP) to the

control PCB.

G. Fasten the roller unit with the fastening screw

(a). Note: Conduct the mechanism inter-

changeability adjustment outlined in Para . 3

to give optimum performance when the drum

assembly is replaced.

Fig. 2-3-1

Fig. 2-3-2

Fig. 2-3-3

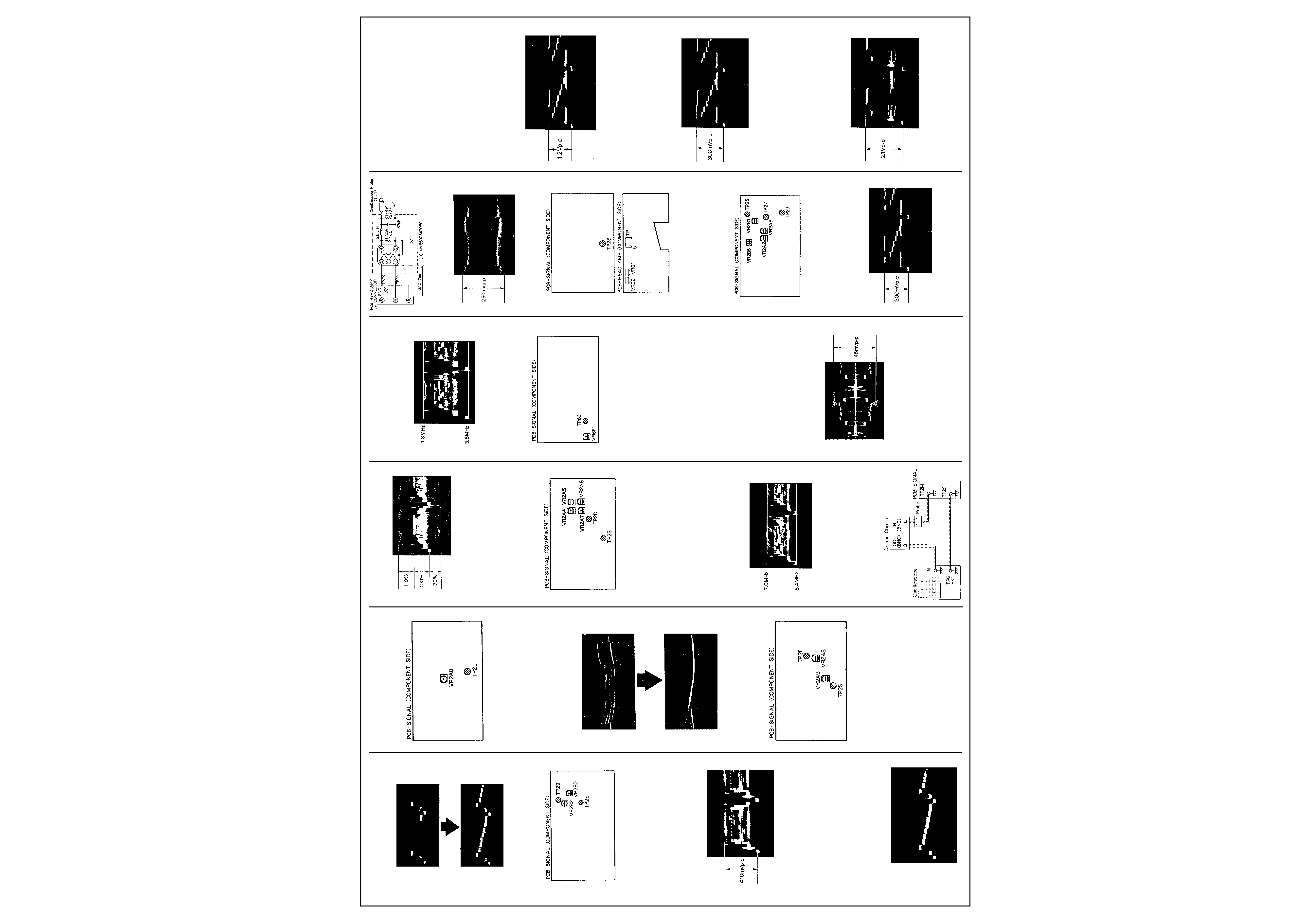

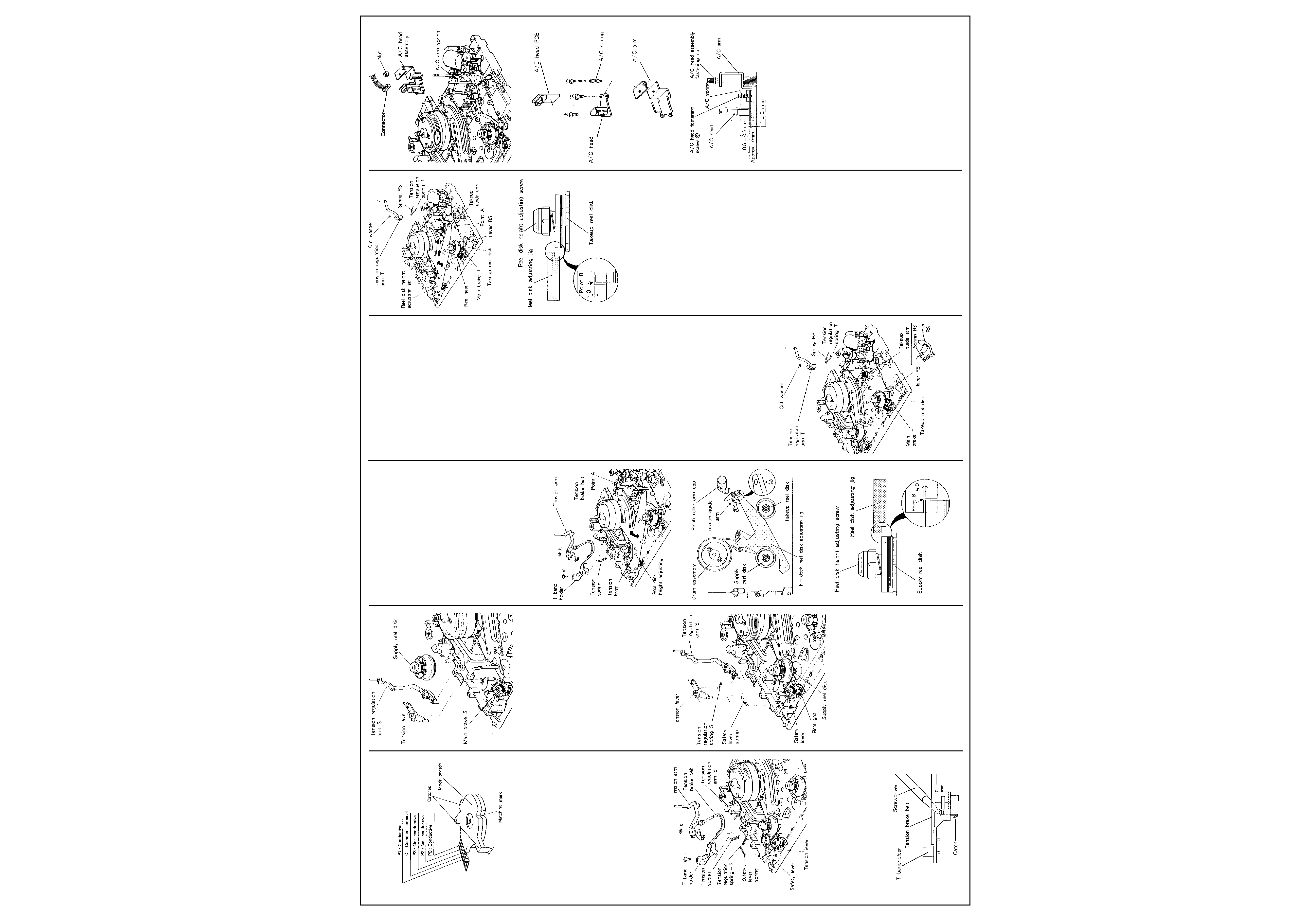

2-4 Upper Drum

2-4-1 Removal (Refer to Fig. 2-4-1.)

A.Unscrew the roller unit fastening screw and

remove the roller unit.

B.Unsolder two inside soldered terminals of

each head on the upper drum.

C.Unscrew the upper drum fastening screws.

D.Remove the upper drum slowly and carefully.

Note: If the upper drum is difficult to remove,

heat the upper drum fastening screw holes

with a soldering iron, and the drum will be

easily removed.

2-4-2 lnstallation (Refer to Fig. 2-4-1.)

Note: Handle the upper drum carefully as the

video heads are fragile.

A.Position the lower drum so that the hole in the

shaft faces the operator. Align the upper drum

with the lower drum so that the CH1 mark on

the upper drum is on the right side, and

couple the drums.

B.Fasten the upper drum with two screws.

(Tighten the screws alternately.)

C.Solder the terminals not soldered on the

upper drum.

D. Clean the video heads as outlined in Para.1-

1.

2-5 Ribbed Belt

2-5-1 Removal (Refer to Fig. 2-5)

A.Remove the screw (a) retaining the holder belt

unit, and remove the holder belt unit.

B.Detach the capstan brake spring from the

tension unit and capstan brake unit.

C.Remove the screw (b) retaining the tension

unit and the nut (c), and remove the tension

unit.

D.Remove the ribbed belt from the capstan

motor and the belt pully.

2-5-2 Installation (Refer to Fig. 2-5-1, 2-5-2)

A.Confirm that the groove of the new ribbed belt

is turned to the inside, as shown in Fig. 2-5-2,

and then install the ribbed belt to the capstan

motor and the belt pulley.

B. lnstall the tension unit to the main plate with

the screw (b) and the nut (c).

C.Fasten the capstan brake spring to the

tension unit and capstan brake unit.

D.Install the holder belt unit to the main plat with

the screw (a).

Note: Make certain that the new belt is free

from grease, before installing.

Fig. 2-4-1

Fig. 2-5-1

Fig. 2-5-2

2-6 Capstan Motor

2-6-1 Removal (Refer to Fig. 2-5, 2-6)

A.Disconnect the flat cable.

B.Detach the capstan brake spring from the

tension unit and capstan brake unit.

C.Remove the screw (a) retaining the tension

unit and the nut (b), and remove the tension

unit.

D.Remove the ribbed belt.

E.Remove three fastening screws shown in Fig.

2-6 and remove the capstan motor.

CAUTION:

Restrain the capstan motor as the three screws

are removed, since an un-restrained motor may

damage other parts of the deck. When perform-

ing removal or installation of the capstan

motortake care that the outside of the rotor's rim

is not greased.(Refer to Fig. 2- 5.)

If greasy components are attached on the

outside of the rotor's rim, wipe them off with a

dry cloth because they may cause defects

during special effects playback.

2-6-2 Installation (Refer to Fig. 2-5, 2-6.)

A.Fasten the motor with three fastening

screws.(Refer to Fig. 2-6.)

B.Install the ribbed belt.

C.Install the tension unit to the main plate with

the screw (a) and nut (b).

D.Fasten the capstan brake spring to the

tension unit and capstan brake unit.

E.Connect the flat cable.

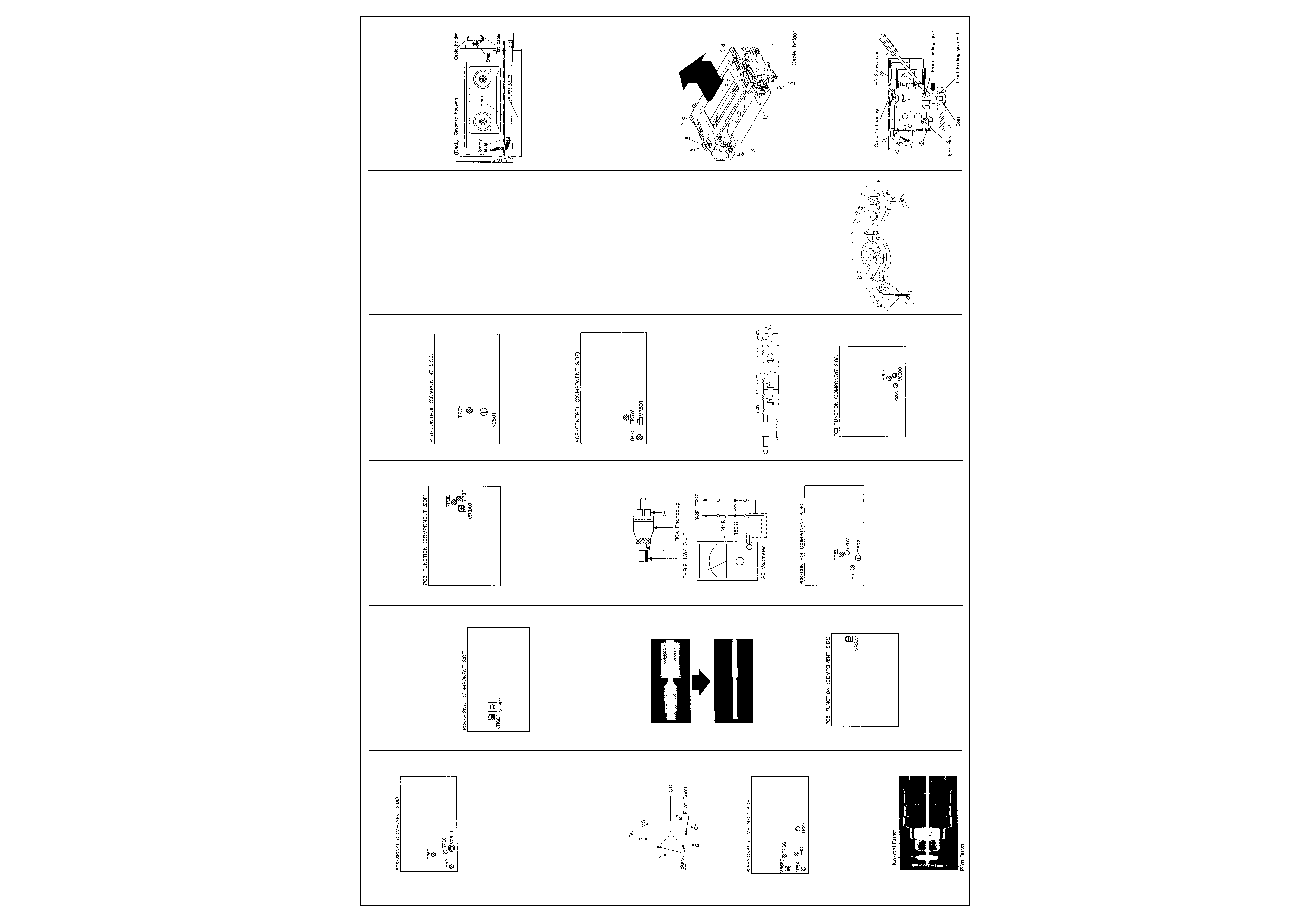

2-7 Loading Motor

2-7-1 Removal (Refer to Fig. 2-7-1, 2-7-2.)

A.Set the VCR to the eject mode.

B.Unscrew the humidity sensor assembly

fastening screw (a) and remove the humidity

sensor assembly. (Refer to Fig. 2-7-1.)

C.Disconnect the wires from the loading motor.

D.Remove two stoppers securing the motor and

the motor holder plate. (Refer to Fig. 2-7-2.)

E.Slide the motor and motor holder plate away,

and then raise them to remove.

F. Unscrew two screws and detach the motor

holder plate from the motor.

G.Disconnect the coupling from the motor.

2-7-2 Installation (Refer to Fig. 2-7-1~2-7-3.)

A.Fasten the coupling to a new loading motor.

(Refer to Fig. 2-7-3.)

B.Fasten the motor holder plate to the motor

with two screws.

C.Place the motor and motor holder plate in the

motor holder at the rear of the deck.

D.Turn the motor shaft so that the coupling on

the loading motors matches the worm gear of

the motor holder. Slide the loading motor

forward and secure it with the stoppers.

E. Solder the leads to the loading motor. (Brown

lead wire to the positive terminal and red lead

wire to the negative terminal.)

F. Fasten the humidity sensor assembly with the

fastening screw (a).(Refer to Fig. 2-7-1.)

Fig. 2-6

Fig. 2-7-1

Fig. 2-7-2

2-8 Pinch Roller

2-8-1 Removal (Refer to Fig. 2-8-1, 2-8-2.)

A.Set the VCR to the eject mode.

B.Remove the pinch roller arm cap and the grip

ring which secures the pinch roller arm

assembly.

C.Pull the pinch roller arm assembly upwards to

remove.

D.Remove the pinch roller cap from the pinch

roller arm, and remove the pinch roller. (Refer

to Fig. 2-8-2.)

Fig. 2-7-3

2-8-2 Installation (Refer to Fig. 2-8-1, 2-8-2.)

A.Assemble the pinch roller cap and the pinch

roller to the pinch roller arm by exercising

care with the installation angle of the pinch

roller cap and the marking of the Pinch Roller.

(Refer to Fig. 2-8-2.)

B.Assemble the pinch roller assembly to the

shaft on the main plate.

C.Secure the pinch roller arm assembly with the

pinch roller arm cap and the grip ring.

Fig. 2-8-1

Fig. 2-8-1

2-9 Mode Switch

Note: Replace the mode switch with the VCR in

the eject mode.

2-9-1 Removal (Refer to Fig. 2-9-1)

A.Unsolder the five soldered joints of the mode

switch from the deck PCB.

B.Unfasten two catches fastening the switch to

the deck PCB assembly. (Exercise care as

the catches may be broken off.)

C.Remove the mode switch slowly while

assuring that the soldered joints are all

unsoldered.

2-9-2 lnstallation (Refer to Fig. 2-9-1,2-9-2.)

A.Line the matching marks of the mode switch.

(Refer to Fig. 2-9-2.)

B.Finally adjust the mode switch so that

continuity at each terminal shall be as given in

the illustration.

C.Fasten the switch to the deck PCB with care

so that the switch shall not turn, and secure

with two catches.(Refer to Fig. 2-9-1.)

D.Solder the five terminals which connect the

mode switch to the deck PCB assembly.

Fig. 2-8-2

Fig. 2-9-1

Mechanical Adjustments

Cont'd