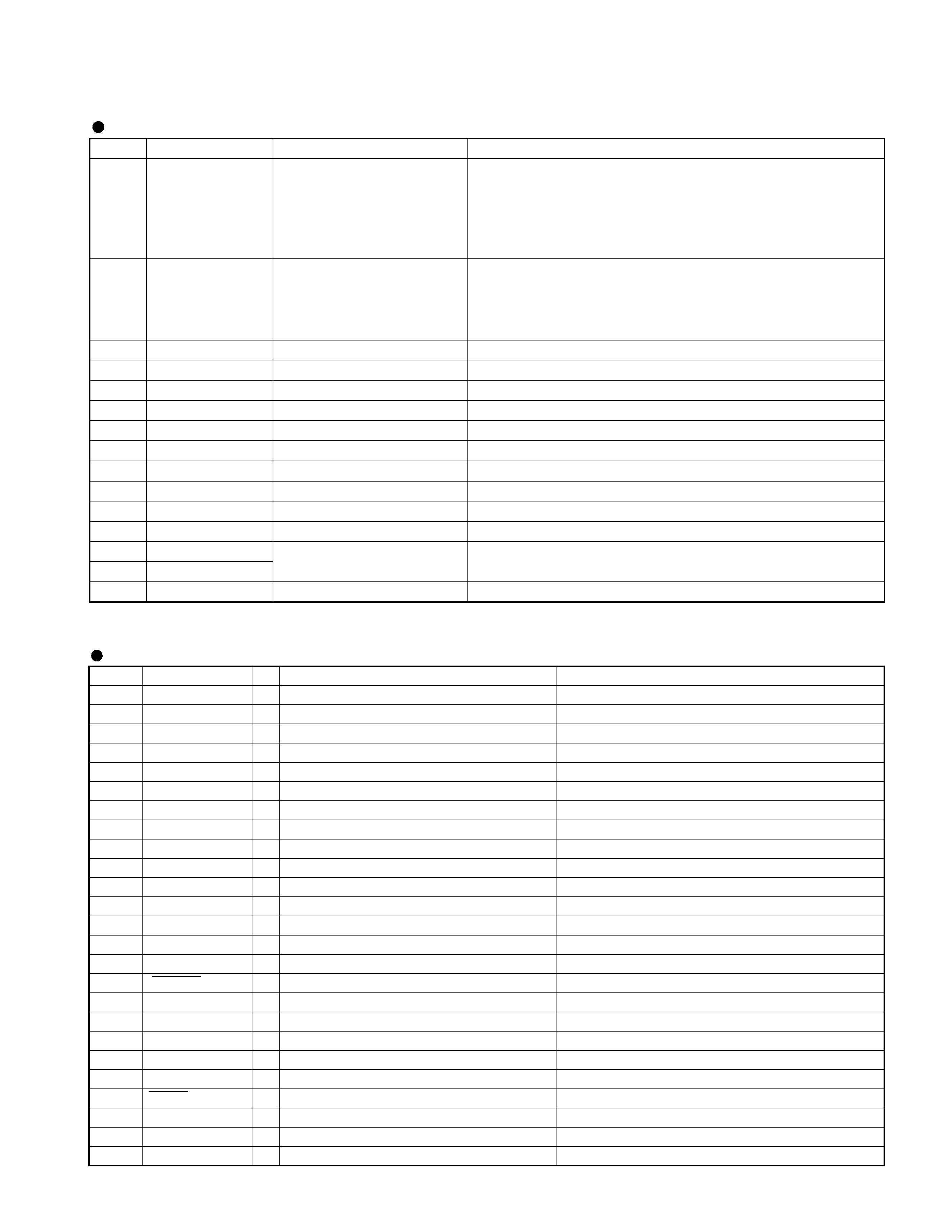

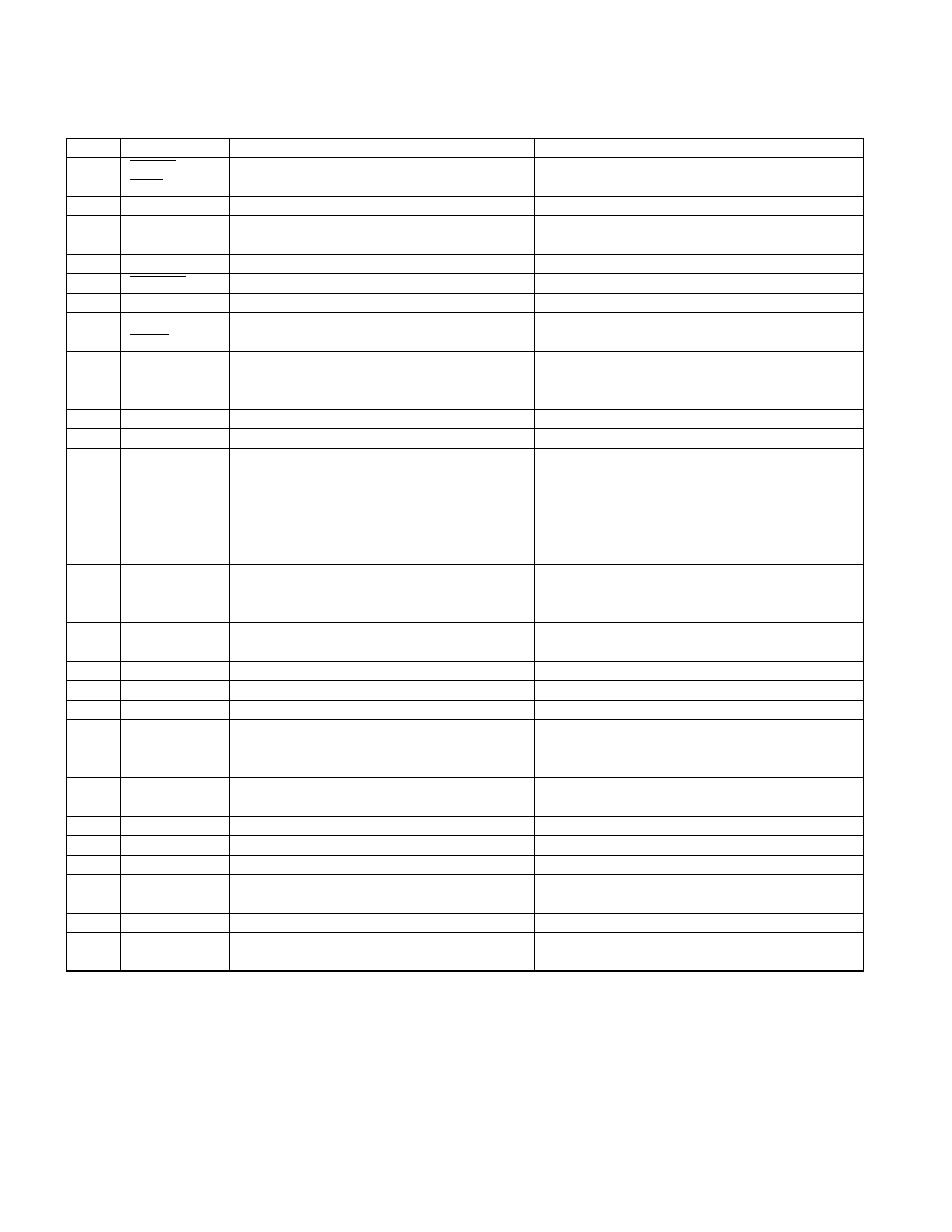

MICROCOMPUTER'S TERMINAL DESCRIPTION

3

X92-3770-00,0-01/X92-3780-00,0-01

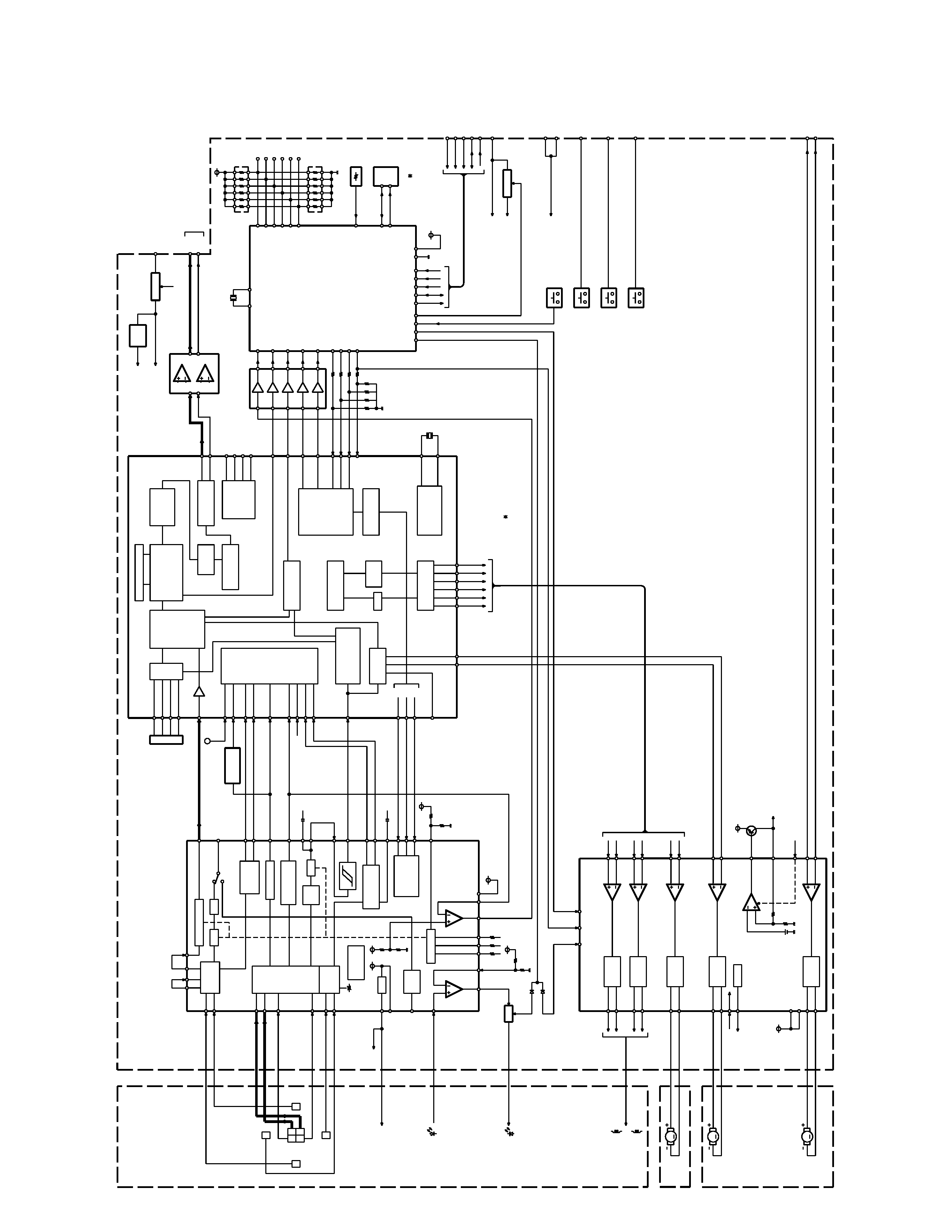

COMPONENT DESCRIPTION

IC1

IC2

IC4

IC5

IC8

IC9

IC11

IC12

Q1

Q2

Q3

Q7

Q10

Q12

Q13

CXA2523AR

CXD2659R

LA6552

NJM4565MD

LP2982-3.3

TC74HCT7007AF

78015FYGC-R08

S-24C01B

2SA1362(Y)

DTA114EUA

2SC4116(Y)

MCH6101

2SA1576A

DTC143EUA

2SA1576A

RF matrix amp.

Digital signal processor

5ch BTL driver

LPF

3.3V AVR

CMOS buffer

MD mechanism MI-COM.

E2PROM

APC

LD SW

Disc reflection detection

3.3V AVR

A 8VSW

P ON 5V SW

RF amplifier (pit and groove switching, AGC, EQ), gain switching

I-V amplifier.

Amplification of the light intensity signal output, peak hold output,

bottom hold output, FE output, TE output, SE output, ADIP binary

output, VREF output and APC PD

EFM decording, EFM digital PLL, ACIRC decording, auto link pro-

cessing, ADIP decording.

Digital servos (focusing, tracking, sled, spindle CLV).

ATRAC decording, 1bit D/A, analog post-filtering, memory control.

Drives actuators and motors, +3.3V REGULATOR

Third active filter

D/A audio +B

Level shifting from 3.3V to 5.0V

Servo control, memory control, system control and interfacing

Servo coefficients and servo adjustment data backup memory

Laser power control.

On at base"L" while laser is OFF.

On when focusing point is passed during upward search.

Servo +B

Analog 8V power supply.

On at base"L"

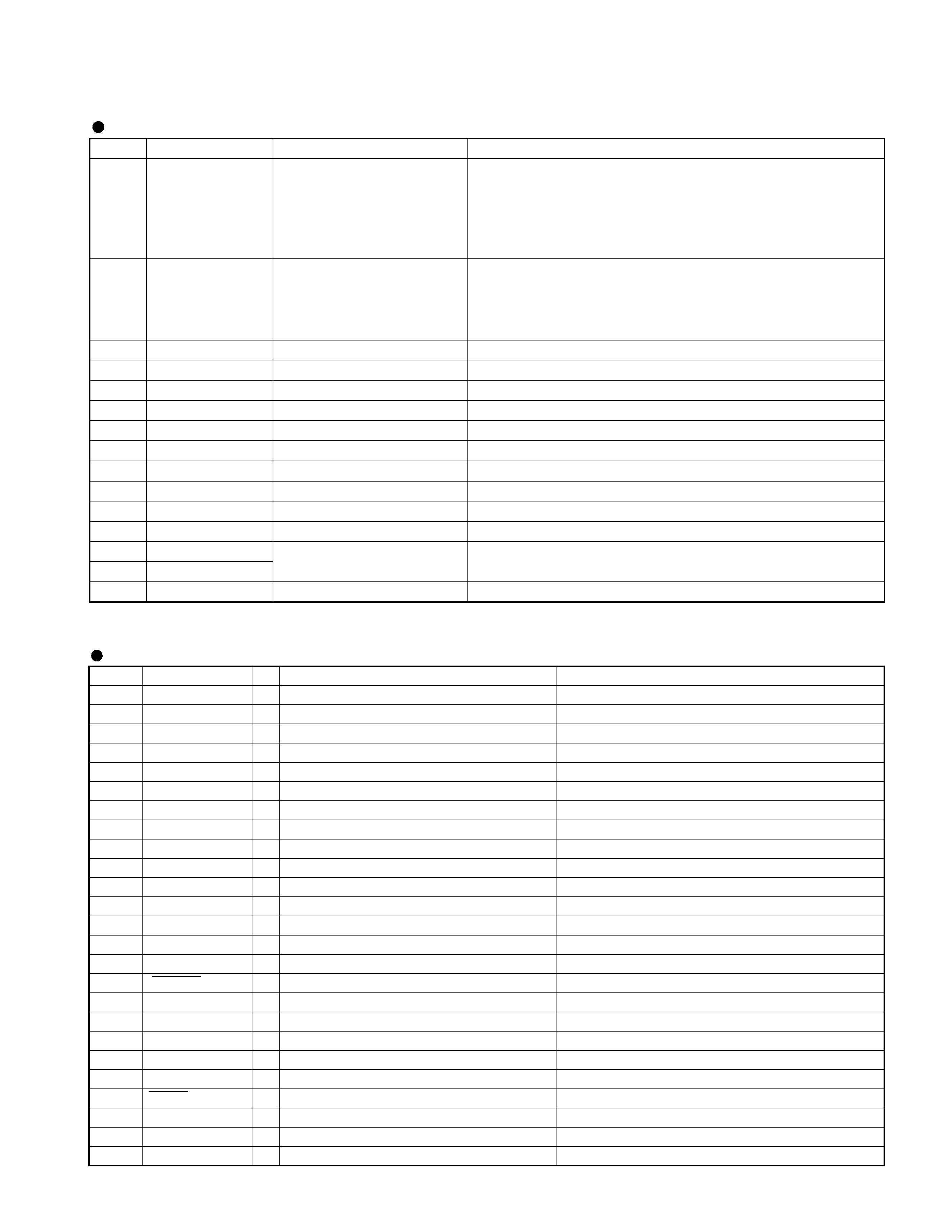

Ref. No. Component Name

Application/Function

Operation/Condition/Compatibility

MD PLAYER UNIT (X33-3040-00/0-01)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

"H" turns normal test mode ON.

"L": 200ms, "H": 300ms

"L": 2655R, 2652AR, "H": 2655BR, 2654R

"H" turns special test mode ON.

"H" turns external input mode ON.

75% or more remains at "H"

IVR-TBAL auto align bus at "H"

AGC auto align bus at "H"

Error count mode at "H"(When it's in text mode)

Reverse polarity at "H".

"H" turns 16M bit operation (fixed on RESET)

"L" when innermost limit is detected.

During 2652AR : ON at "H", during 2654R : ON at "L"

Active : "L"

Latch at falling edge

Test mode input 0

Groove area jump time selection input

Destination selector 2

Test mode input 3

E2PROM external input test mode

Test mode memory remainder output

OPEN

OPEN

No auto align mode input

No auto align mode input

C1 error count mode input

GND

Internal status input from DSP LSI

DAC output polarity reversal input

DRAM size selection input

Pickup innermost limit detection

OPEN

OPEN

OPEN

De-emphasis output to external DAC

Reset output to DSP LSI and servo driver IC

Latch output to DSP LSI

OPEN

Pin No.

Microprocessor : 78015FYGC-R08 (X33 : IC11)

Description

Processing Operation

I

I

I

I

I

O

O

O

I

I

I

I

I

I

I

I

O

O

O

O

O

O

O

I/O

TEST0

JTIME

TYPE2

TEST3

TESTE

M REM

NC

NC

VSS

IVRTBAL PASS

AGC PASS

C1 COUNT

NC

SENS

AUDIO INV

4M/16M

LIMSW

NC

NC

NC

DEEM

XRST

XLAT

VSS

NC

Pin Name