5

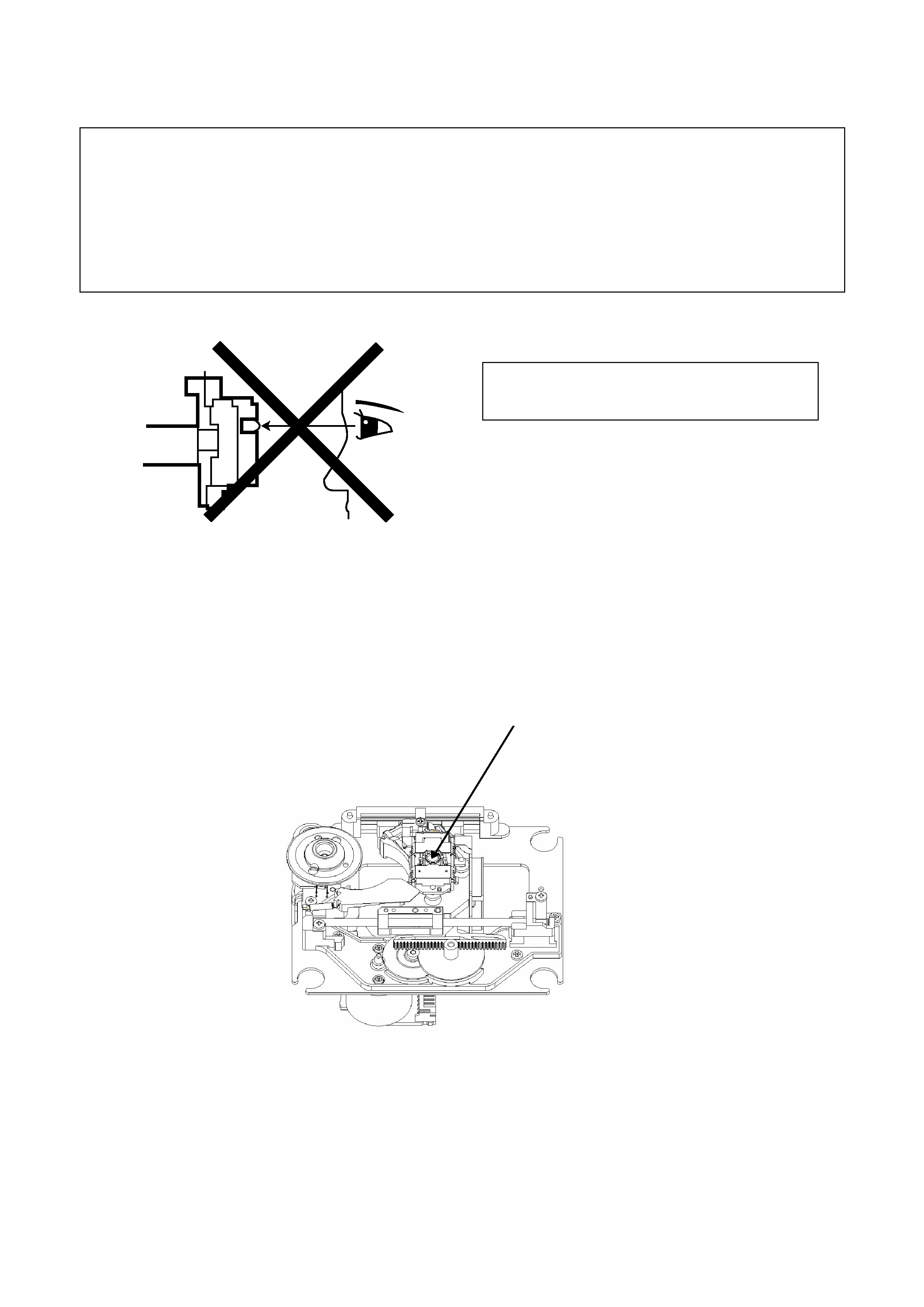

HANDLING LASER PICKUP

The laser diode in the optical system of this receiver can be damaged by electrostatic discharge from clothes,

body, etc. Proper electrostatic grounding for service personnel is required during servicing.

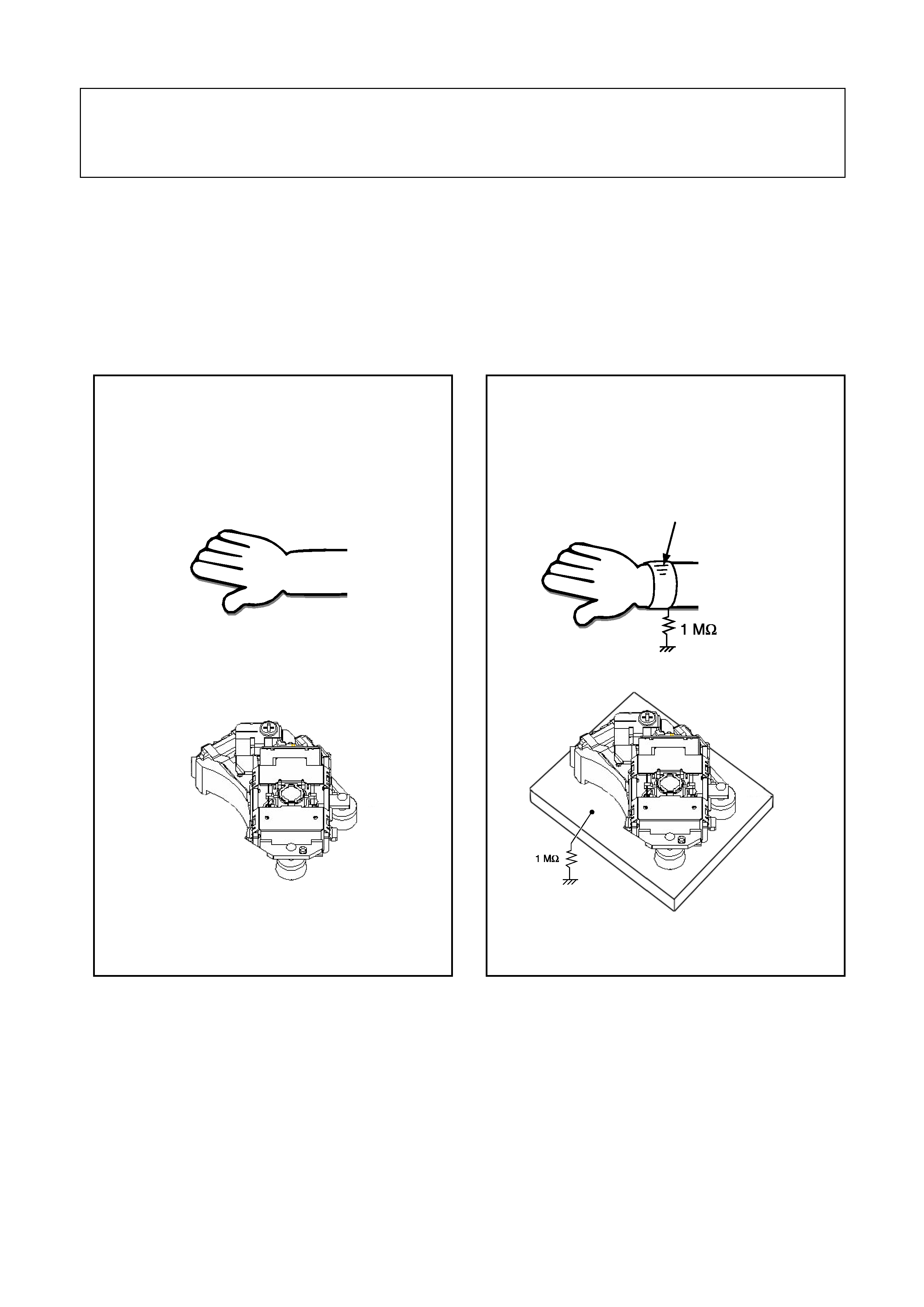

BEFORE REPAIRING THE DVD MECHANISM

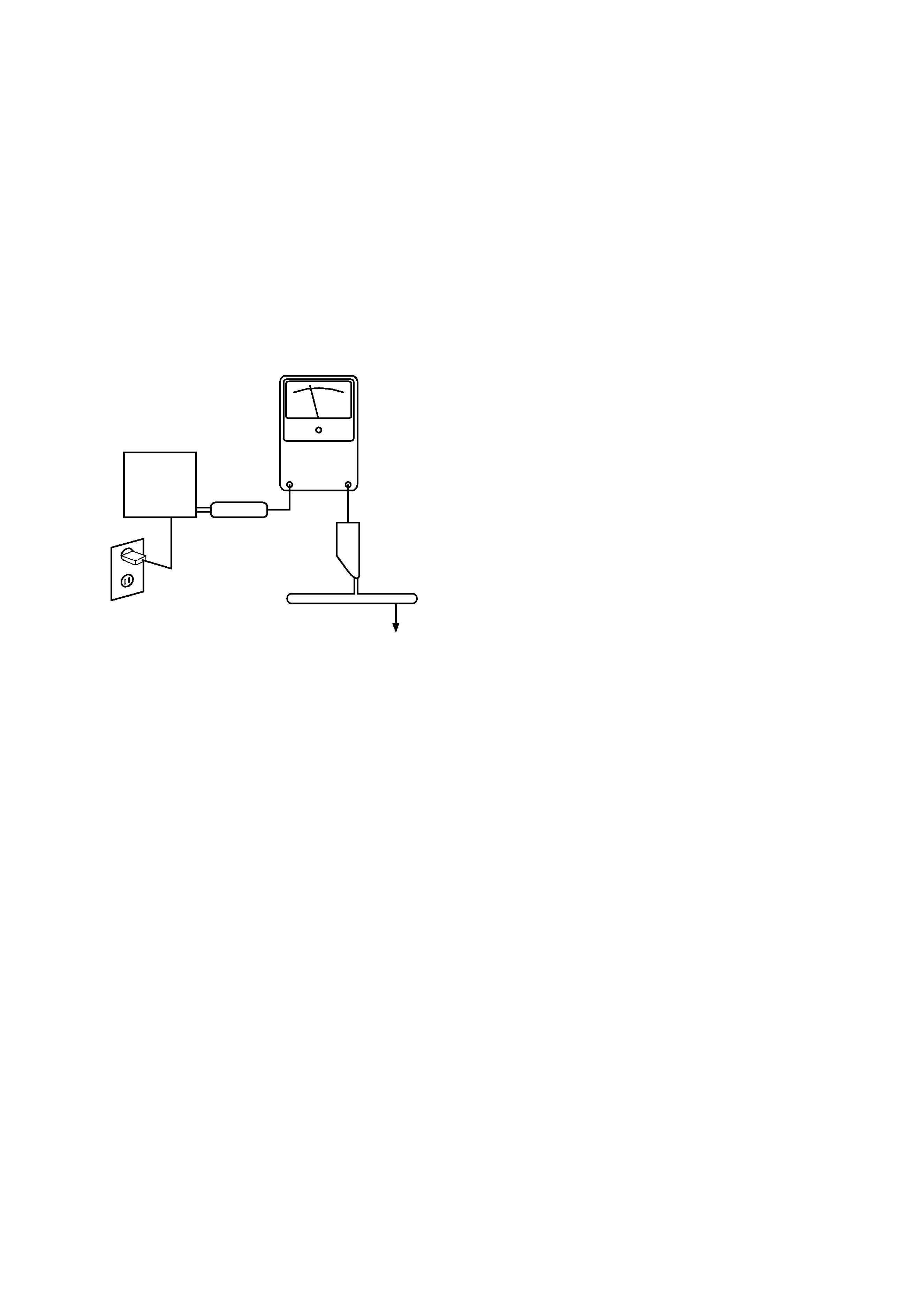

a. Human Body Grounding:

Many of the components used in this compact disc player, including the laser pickup, are sensitive to electrostatic

discharge.

Service personnel should be grounded with an electrostatic armband (1M ohm).

Caution: Static charge on clothing does not escape through a body grounding wristband. Be careful not to contact the

pickup or electrical components with your clothing.

b. Workbench and Tool Grounding:

A properly-grounded electroconductive plate (1 M ohm) or metal sheet should be fitted to the workbench surface.

Tools and instruments (soldering irons, scopes, etc.) should be grounded to prevent AC leakage.

c. Make two standard ESD solder bridges on the Laser optic PC Board

Before disassembly of mechanism or disconnect any cables in it, make two standard ESD solder bridges on the laser

optic PC Board.

Ground conductive wristband

for body

INCORRECT

CORRECT