XV-DV370

4

12

34

1

234

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

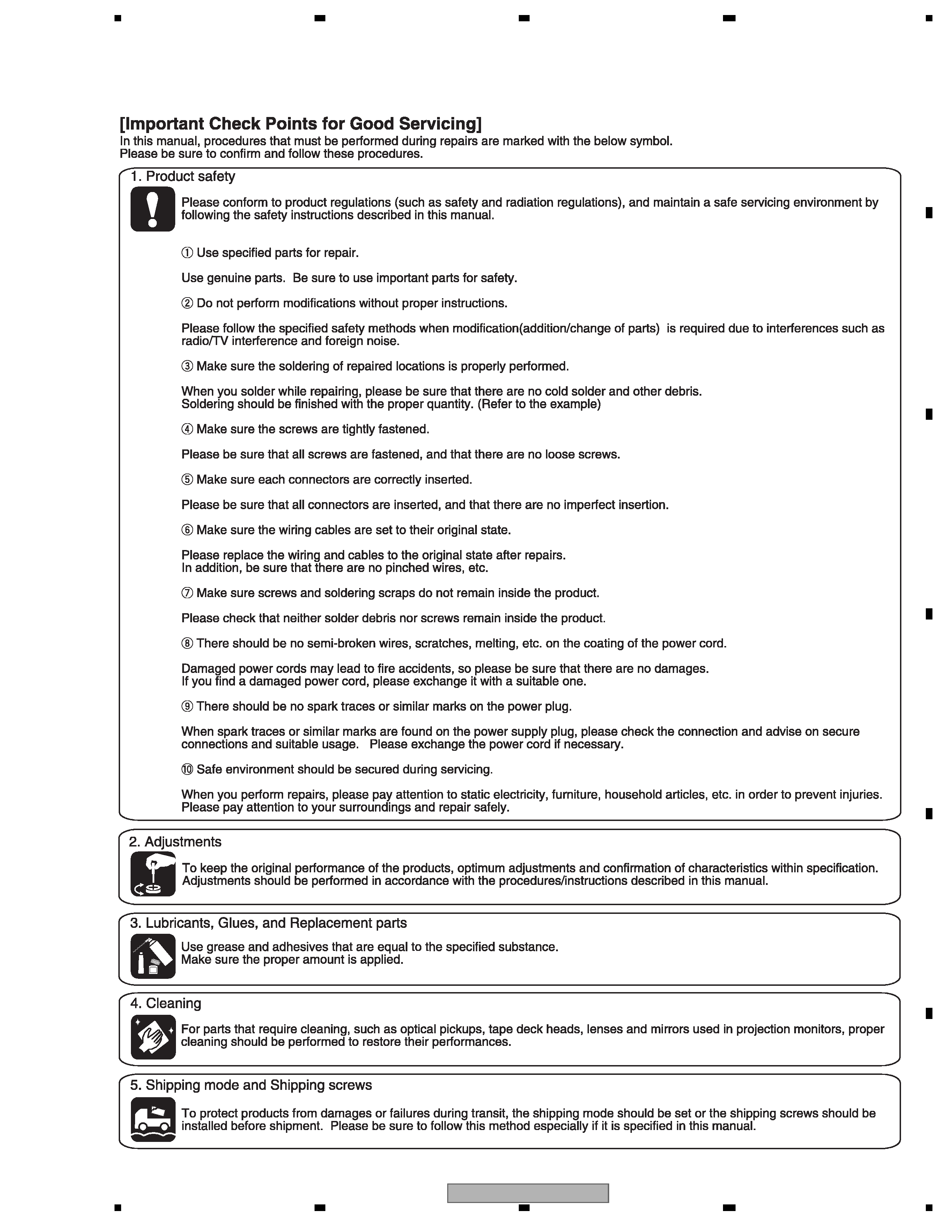

1. SERVICE PRECAUTIONS ............................................................................................................................... 5

1.1 NOTES ON SOLDERING .......................................................................................................................... 5

1.2 CAUTION................................................................................................................................................... 5

2. SPECIFICATIONS............................................................................................................................................ 6

2.1 SPECIFICATIONS and ACCESORRIES ................................................................................................... 6

2.2 PANEL FACILITIES.................................................................................................................................... 7

3. BASIC ITEMS FOR SERVICE........................................................................................................................ 10

3.1 CHECK POINTS AFTER SERVICING..................................................................................................... 10

3.2 PCB LOCATIONS .....................................................................................................................................11

3.3 JIGS LIST ................................................................................................................................................ 12

3.4 CLEANING............................................................................................................................................... 12

4. BLOCK DIAGRAM.......................................................................................................................................... 14

4.1 OVERALL WIRING CONNECTION DIAGRAM and LOAB ASSY ........................................................... 14

4.2 OVERALL BLOCK DIAGRAM.................................................................................................................. 16

5. DIAGNOSIS.................................................................................................................................................... 18

5.1 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP................................... 18

5.2 DVD TROUBLE SHOOTING ................................................................................................................... 19

5.3 CIRCUIT DESCRIPTION OF DIGITAL AMP. SECTION .......................................................................... 22

5.4 SPECIFICATIONS FOR THE PROTECTION CIRCUITS FOR THE DIGITAL AMPLIFIER..................... 23

5.5 PASS/FAIL TEST PROCEDURE OF HDMI TRANSMITTER IC.............................................................. 24

6. SERVICE MODE ............................................................................................................................................ 25

6.1 TEST MODE ............................................................................................................................................ 25

6.2 DISPLAY SPECIFICATION OF THE TEST MODE.................................................................................. 26

6.3 FUNCTIONAL SPECIFICATION OF THE SHORTCUT KEY .................................................................. 27

6.4 SPECIFICATION OF MODEL INFORMATION DISPLAY ........................................................................ 28

6.5 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE ................................................................... 29

6.6 SERVICE TEST MODE ........................................................................................................................... 30

7. DISASSEMBLY .............................................................................................................................................. 33

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 40

8.1 ADJUSTMENT......................................................................................................................................... 40

8.2 ID NUMBER AND ID DATA SETTING ..................................................................................................... 45

9. EXPLODED VIEWS AND PARTS LIST.......................................................................................................... 48

9.1 PACKING SECTION ................................................................................................................................ 48

9.2 EXTERIOR SECTION.............................................................................................................................. 50

9.3 06 LOADER ASSY................................................................................................................................... 52

9.4 TRAVERSE MECHANISM ASSY-S ......................................................................................................... 54

10. SCHEMATIC DIAGRAM............................................................................................................................... 56

10.1 DVD MAIN ASSY (1/5) .......................................................................................................................... 56

10.2 DVD MAIN ASSY (2/5) .......................................................................................................................... 58

10.3 DVD MAIN ASSY (3/5) .......................................................................................................................... 60

10.4 DVD MAIN ASSY (4/5) .......................................................................................................................... 62

10.5 DVD MAIN ASSY (5/5) .......................................................................................................................... 64

10.6 DAMP ASSY (1/2).................................................................................................................................. 66

10.7 DAMP ASSY (2/2).................................................................................................................................. 68

10.8 DISPLAY, USB, LED and KEY ASSYS .................................................................................................. 70

10.9 POWER SUPPLY UNIT ......................................................................................................................... 72

10.10 WAVEFORMS...................................................................................................................................... 74

11. PCB CONNECTION DIAGRAM.................................................................................................................... 77

11.1 LOAB ASSY ........................................................................................................................................... 77

11.2 DVD MAIN ASSY ................................................................................................................................... 78

11.3 DAMP ASSY .......................................................................................................................................... 82

11.4 DISPLAY, USB, LED and KEY ASSYS .................................................................................................. 84

11.5 POWER SUPPLY UNIT ......................................................................................................................... 86

12. PCB PARTS LIST ......................................................................................................................................... 88