SX-SW515

4

12

34

12

3

4

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

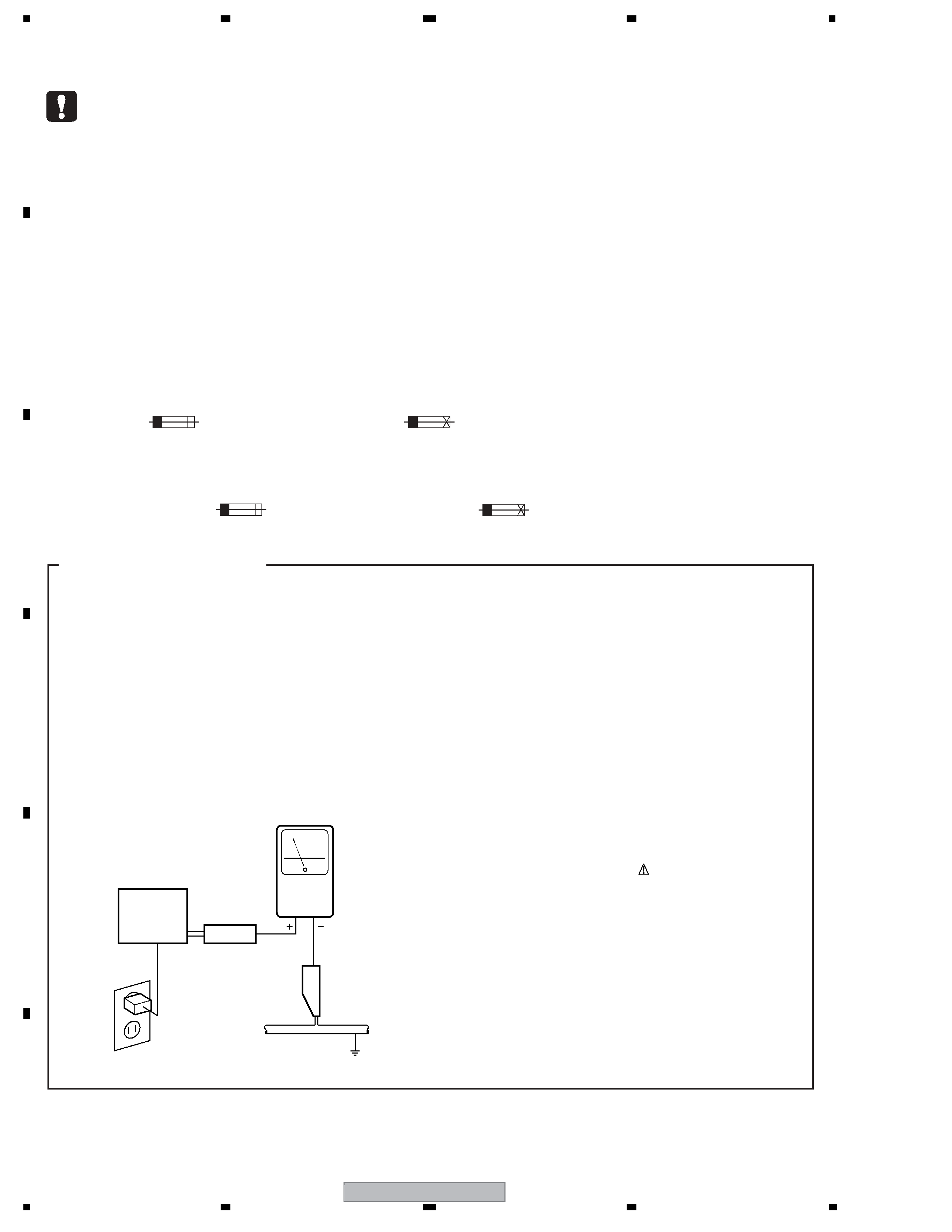

Important Check Points for Good Servicing......................................................................................................... 3

CONTENTS ......................................................................................................................................................... 4

1. SERVICE PRECAUTIONS ............................................................................................................................... 5

2. SPECIFICATIONS ............................................................................................................................................ 6

2.1 ACCESSORIES ......................................................................................................................................... 6

2.2 SPECIFICATIONS...................................................................................................................................... 6

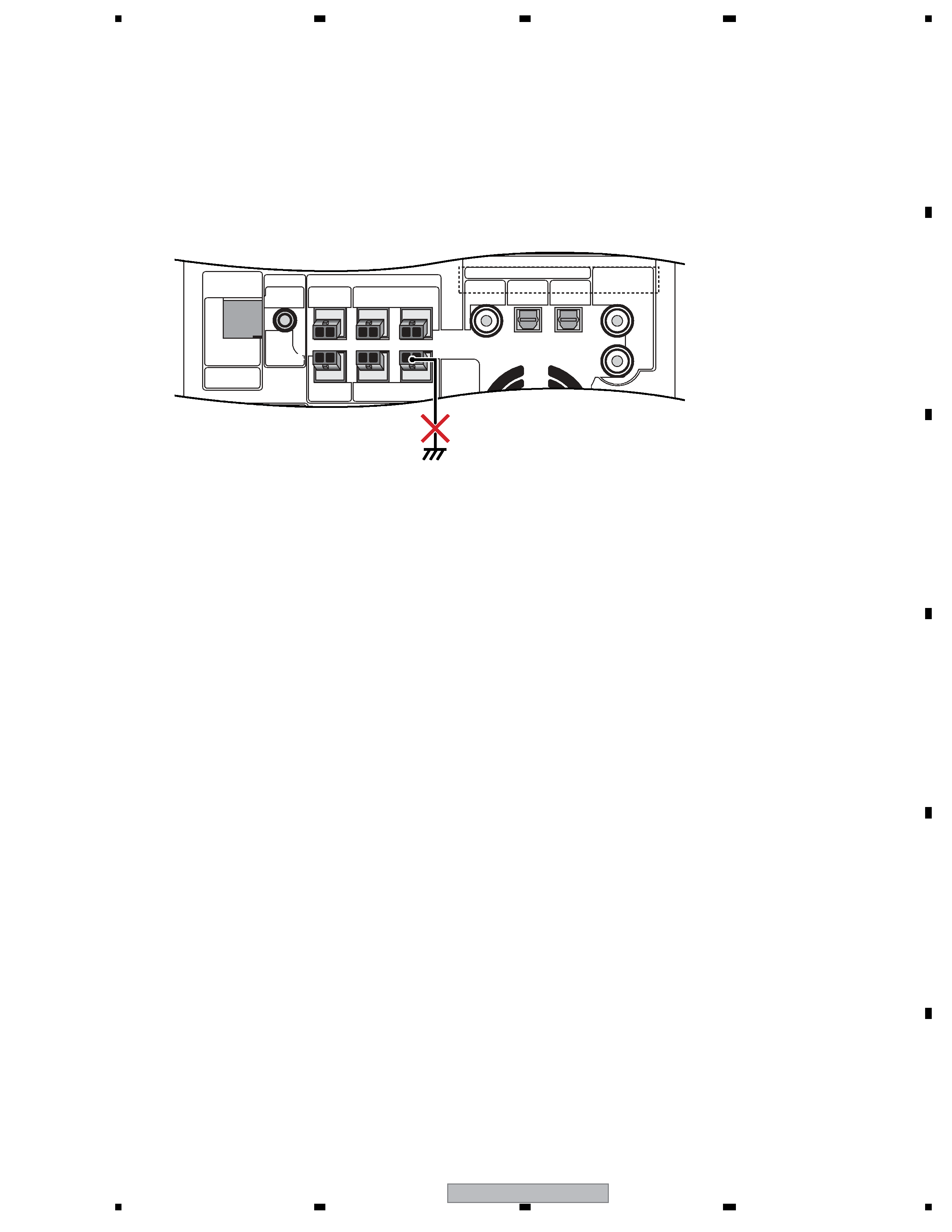

2.3 PANEL FACILITIES .................................................................................................................................... 7

3. BASIC ITEMS FOR SERVICING .................................................................................................................... 11

3.1 CHECK POINTS AFTER SERVICING..................................................................................................... 11

3.2 PCB LOCATIONS .................................................................................................................................... 12

3.3 JIGS LIST ................................................................................................................................................ 13

4. BLOCK DIAGRAM .......................................................................................................................................... 14

4.1 OVERALL BLOCK DIAGRAM.................................................................................................................. 14

5. DIAGNOSIS .................................................................................................................................................... 16

5.1 CIRCUIT DESCRIPTION ......................................................................................................................... 16

5.1.1 CIRCUIT DESCRIPTION OF DIGITAL AMP. SECTION .................................................................... 16

5.1.2 SPECIFICATIONS FOR THE PROTECTION CIRCUITS FOR THE DIGITAL AMPLIFIER ............... 17

5.1.3 CONDITIONS FOR SWITCHING THE ROTATION SPEED OF THE FAN ........................................ 18

6. SERVICE MODE ............................................................................................................................................ 19

6.1 SERVICE TEST MODE............................................................................................................................ 19

7. DISASSEMBLY ............................................................................................................................................... 22

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 25

8.1 ADJUSTMENT ......................................................................................................................................... 25

9. EXPLODED VIEWS AND PARTS LIST .......................................................................................................... 26

9.1 PACKING SECTION ................................................................................................................................ 26

9.2 EXTERIOR SECTION.............................................................................................................................. 28

9.3 DISPLAY UNIT ......................................................................................................................................... 30

10. SCHEMATIC DIAGRAM ............................................................................................................................... 32

10.1 MAIN ASSY (1/5) ................................................................................................................................... 32

10.2 MAIN ASSY (2/5) ................................................................................................................................... 34

10.3 MAIN ASSY (3/5) ................................................................................................................................... 36

10.4 MAIN ASSY (4/5) ................................................................................................................................... 38

10.5 MAIN ASSY (5/5) ................................................................................................................................... 40

10.6 AC INLET, CONNECT and FL ASSYS .................................................................................................. 42

10.7 JACK TX ASSY ...................................................................................................................................... 44

10.8 POWER SUPPLY UNIT.......................................................................................................................... 46

10.9 WAVEFORMS ........................................................................................................................................ 48

11. PCB CONNECTION DIAGRAM ................................................................................................................... 49

11.1 MAIN ASSY ........................................................................................................................................... 50

11.2 AC INLET ............................................................................................................................................... 54

11.3 CONNECT ASSY................................................................................................................................... 55

11.4 FL ASSY ................................................................................................................................................ 56

11.5 JACK TX ASSY ...................................................................................................................................... 58

11.6 POWER SUPPLY UNIT.......................................................................................................................... 60

11.7 DISPLAY ................................................................................................................................................ 62

12. PCB PARTS LIST ......................................................................................................................................... 63