5

SVM-1000

5

6

7

8

5

6

7

8

A

B

C

D

E

F

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

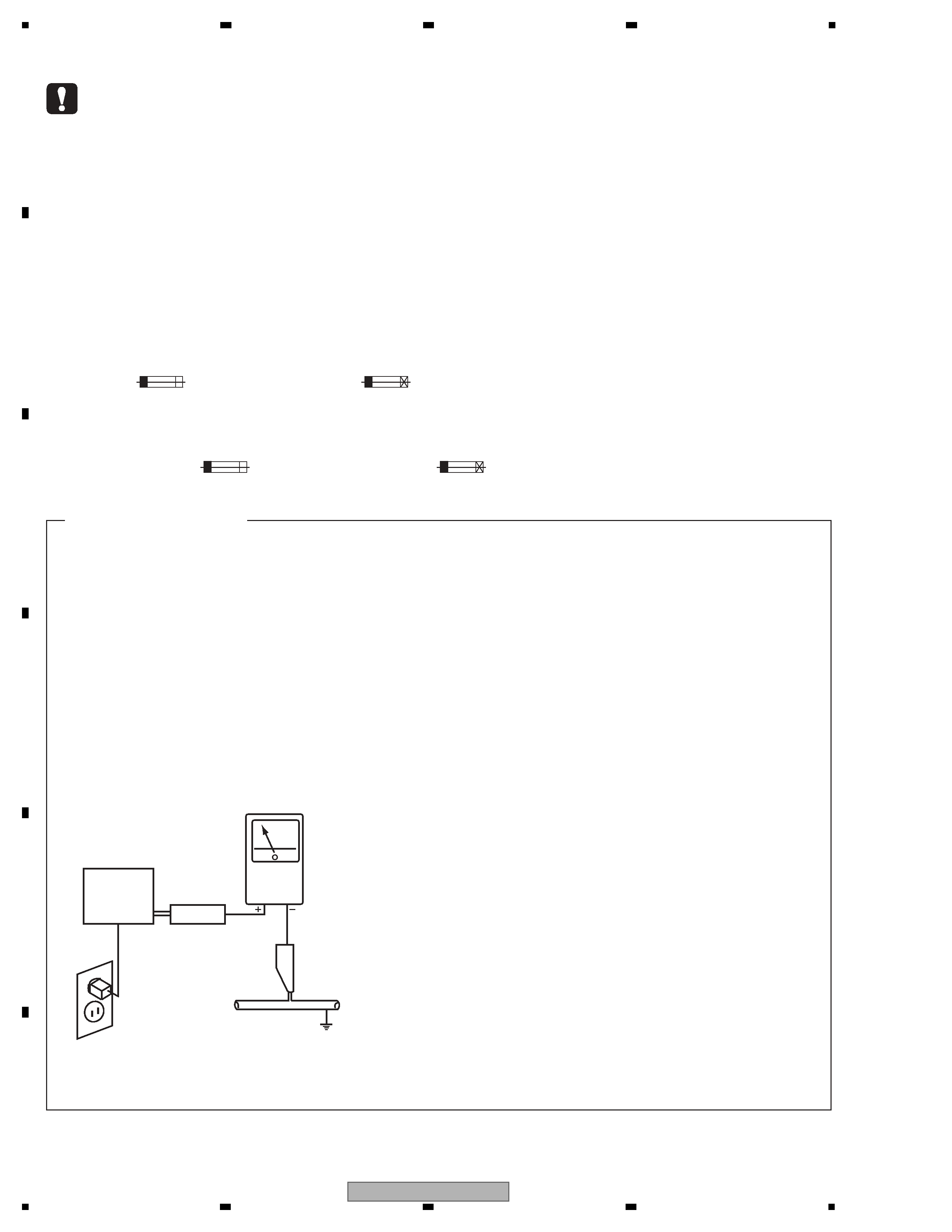

1. SERVICE PRECAUTIONS ................................................................................................................................7

1.1 NOTES ON SOLDERING ...........................................................................................................................7

2. SPECIFICATIONS.............................................................................................................................................7

2.1 ACCESSORIES ..........................................................................................................................................7

2.2 SPECIFICATIONS ......................................................................................................................................8

2.3 PANEL FACILITIES.....................................................................................................................................9

3. BASIC ITEMS FOR SERVICE ........................................................................................................................13

3.1 CHECK POINTS AFTER SERVICING .....................................................................................................13

3.2 PCB LOCATION .......................................................................................................................................14

4. BLOCK DIAGRAM ..........................................................................................................................................16

4.1 OVERALL WIRING DIAGRAM .................................................................................................................16

4.2 AUDIO BLOCK DIAGRAM........................................................................................................................18

4.3 VIDEO BLOCK DIAGRAM........................................................................................................................20

4.4 FUNCTION BLOCK DIAGRAM ................................................................................................................22

5. DIAGNOSIS ....................................................................................................................................................24

5.1 DIAGNOSIS FLOW...................................................................................................................................24

5.2 POWER ON SEQUENCE.........................................................................................................................25

6. SERVICE MODE .............................................................................................................................................27

6.1 LIST OF PAGES IN SERVICE MODE ......................................................................................................27

6.2 SERVICE MODE ......................................................................................................................................27

6.3 SERVICE MODE IDENTIFICATION .........................................................................................................28

6.4 LIST OF PAGES IN TEST MODO ............................................................................................................33

6.5 TEST MODE.............................................................................................................................................34

6.6 TEST MODE IDENTIFICATION................................................................................................................35

6.7 HOW TO USB DOWNLOAD .....................................................................................................................41

6.8 NOTES ON VARIOUS SETTINGS WHEN THE UNIT ARE REPLACED .................................................43

7. DISASSEMBLY ...............................................................................................................................................44

8. EACH SETTING AND ADJUSTMENT ............................................................................................................55

9. EXPLODED VIEWS AND PARTS LIST...........................................................................................................56

9.1 PACKING SECTION .................................................................................................................................56

9.2 EXTERIOR SECTION ..............................................................................................................................58

9.3 BOTTOM SECTION..................................................................................................................................60

9.4 OPERATION PANEL SECTION................................................................................................................62

9.5 LCD PANEL SECTION .............................................................................................................................64

10. SCHEMATIC DIAGRAM ................................................................................................................................66

10.1 AUD1 ASSY (1/5) ...................................................................................................................................66

10.2 AUD1 ASSY (2/5) ...................................................................................................................................68

10.3 AUD1 ASSY (3/5) ...................................................................................................................................70

10.4 AUD1 ASSY (4/5) ...................................................................................................................................72

10.5 AUD1 ASSY (5/5) ...................................................................................................................................74

10.6 AUD2 ASSY (1/5) ...................................................................................................................................76

10.7 AUD2 ASSY (2/5) ...................................................................................................................................78

10.8 AUD2 ASSY (3/5) ...................................................................................................................................80

10.9 AUD2 ASSY (4/5) ...................................................................................................................................82

10.10 AUD2 ASSY (5/5) .................................................................................................................................84

10.11 VIO1 ASSY ...........................................................................................................................................86

10.12 MJCK, VIN3 and VIO2 ASSYS.............................................................................................................88

10.13 MAIN ASSY (1/9)..................................................................................................................................90

10.14 MAIN ASSY (2/9)..................................................................................................................................94

10.15 MAIN ASSY (3/9)..................................................................................................................................98

10.16 MAIN ASSY (4/9)................................................................................................................................102

10.17 MAIN ASSY (5/9)................................................................................................................................106

10.18 MAIN ASSY (6/9)................................................................................................................................110

10.19 MAIN ASSY (7/9)................................................................................................................................114

10.20 MAIN ASSY (8/9)................................................................................................................................118

10.21 MAIN ASSY (9/9)................................................................................................................................122

10.22 SCPU ASSY (1/2)...............................................................................................................................126

10.23 SCPU ASSY (2/2)...............................................................................................................................130

10.24 CTL1 ASSY ........................................................................................................................................134

10.25 CTL2A ASSY ......................................................................................................................................136

10.26 CTL2B, CFD1, CFD2, CFD3 and CFD4 ASSYS ................................................................................138

10.27 INVT ASSY .........................................................................................................................................140

10.28 CTL3R ASSY......................................................................................................................................142