5

PDP-LX6090

5

6

7

8

5

6

7

8

A

B

C

D

E

F

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

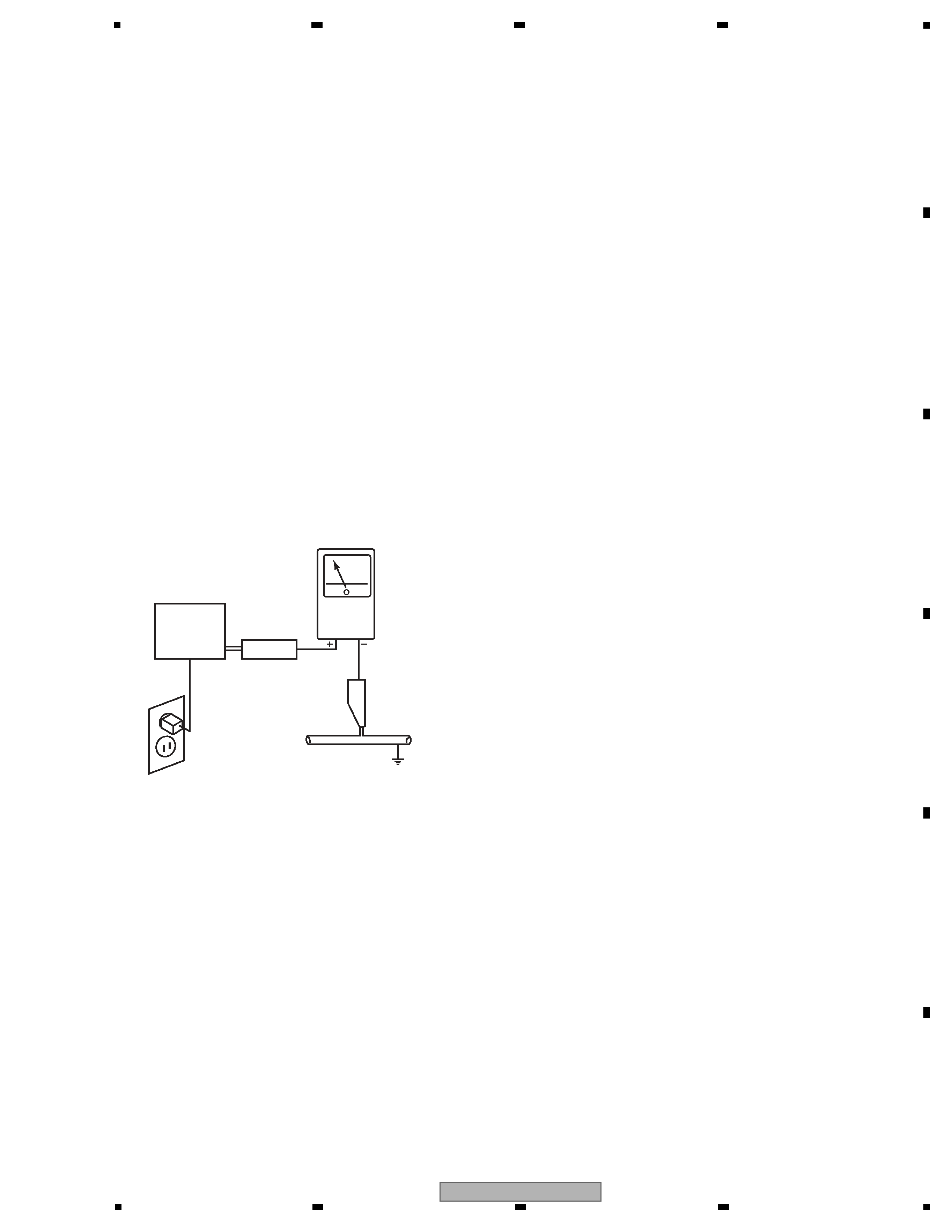

1. SERVICE PRECAUTIONS .................................................................................................................................................... 6

1.1 NOTES ON SOLDERING ............................................................................................................................................... 6

1.2 CHARGED SECTION AND HIGH VOLTAGE GENERATING POINT ............................................................................. 7

2. SPECIFICATIONS................................................................................................................................................................. 8

2.1 ACCESSORIES .............................................................................................................................................................. 8

2.2 SPECIFICATIONS .......................................................................................................................................................... 9

2.3 PANEL FACILITIES....................................................................................................................................................... 10

3. BASIC ITEMS FOR SERVICE ............................................................................................................................................ 13

3.1 CHECK POINTS AFTER SERVICING ......................................................................................................................... 13

3.2 QUICK REFERENCE ................................................................................................................................................... 14

3.3 PCB LOCATIONS ......................................................................................................................................................... 16

4. BLOCK DIAGRAM .............................................................................................................................................................. 18

4.1 OVERALL WIRING DIAGRAM (1/2) ............................................................................................................................. 18

4.2 OVERALL WIRING DIAGRAM (2/2) ............................................................................................................................. 20

4.3 OVERALL BLOCK DIAGRAM (1/2) .............................................................................................................................. 22

4.4 OVERALL BLOCK DIAGRAM (2/2) .............................................................................................................................. 24

4.5 POWER SUPPLY UNIT ................................................................................................................................................ 26

4.6 60F X DRIVE ASSY...................................................................................................................................................... 28

4.7 60F Y DRIVE, 60F SCAN A, B, C and D ASSYS ......................................................................................................... 29

4.8 POWER SUPPLY BLOCK of 60F X, Y DRIVE and 60F SCAN A, B, C and D ASSYS ................................................ 30

4.9 60F ADDRESS L and S ASSYS................................................................................................................................... 31

4.10 60F DIGITAL ASSY .................................................................................................................................................... 32

4.11 POWER SUPPLY BLOCK of MAIN ASSY .................................................................................................................. 34

4.12 IO_AUDIO ASSY ........................................................................................................................................................ 36

4.13 LED and IR ASSYS .................................................................................................................................................... 38

5. DIAGNOSIS ........................................................................................................................................................................ 39

5.1 POWER SUPPLY OPERATION .................................................................................................................................... 39

5.2 DIAGNOSIS FLOWCHART OF FAILURE ANALYSIS .................................................................................................. 45

5.3 DIAGNOSIS OF PD (POWER-DOWN)......................................................................................................................... 66

5.4 DIAGNOSIS OF SD (SHUTDOWN) ............................................................................................................................. 70

5.5 NON-FAILURE INFORMATION .................................................................................................................................... 74

5.6 OUTLINE OF THE OPERATION .................................................................................................................................. 76

5.7 OUTLINE OF RS-232C COMMAND ............................................................................................................................ 81

5.8 LIST OF RS-232C COMMANDS .................................................................................................................................. 82

5.9 DETAILS OF EACH COMMANDS ................................................................................................................................ 91

6. SERVICE FACTORY MODE ............................................................................................................................................. 105

6.1 OUTLINE OF THE SERVICE FACTORY MODE ........................................................................................................ 105

6.2 DETAILS OF FACTORY MENU .................................................................................................................................. 113

7. DISASSEMBLY ................................................................................................................................................................. 137

7.1 FLOWCHART OF REMOVAL ORDER ....................................................................................................................... 137

7.2 DISASSEMBLY ........................................................................................................................................................... 138

8. EACH SETTING AND ADJUSTMENT .............................................................................................................................. 149

8.1 ADJUSTMENT REQUIRED WHEN THE UNIT IS REPAIRED OR REPLACED ........................................................ 149

8.2 BACKUP OF THE EEPROM (DIGITAL ASSY) ........................................................................................................... 152

8.3 HOW TO CLEAR HISTORY DATA .............................................................................................................................. 155

8.4 ADJUSTMENT WHEN THE SERVICE PANEL ASSY IS REPLACED ....................................................................... 156

8.5 ADJUSTMENT WHEN THE DRIVE ASSYS ARE REPLACED.................................................................................. 166

8.6 ADJUSTMENT WHEN THE MAIN OR IO_AUDIO ASSY IS REPLACED.................................................................. 169

9. EXPLODED VIEWS AND PARTS LIST............................................................................................................................. 170

9.1 PACKING SECTION ................................................................................................................................................... 170

9.2 REAR SECTION......................................................................................................................................................... 172

9.3 FRONT SECTION ...................................................................................................................................................... 174

9.4 CHASSIS SECTION (1/2)........................................................................................................................................... 176

9.5 CHASSIS SECTION (2/2)........................................................................................................................................... 178

9.6 PANEL CHASSIS SECTION....................................................................................................................................... 180

9.7 MULTIBASE SECTION............................................................................................................................................... 182

9.8 PDP SERVICE ASSY ................................................................................................................................................. 184