4

CX-977

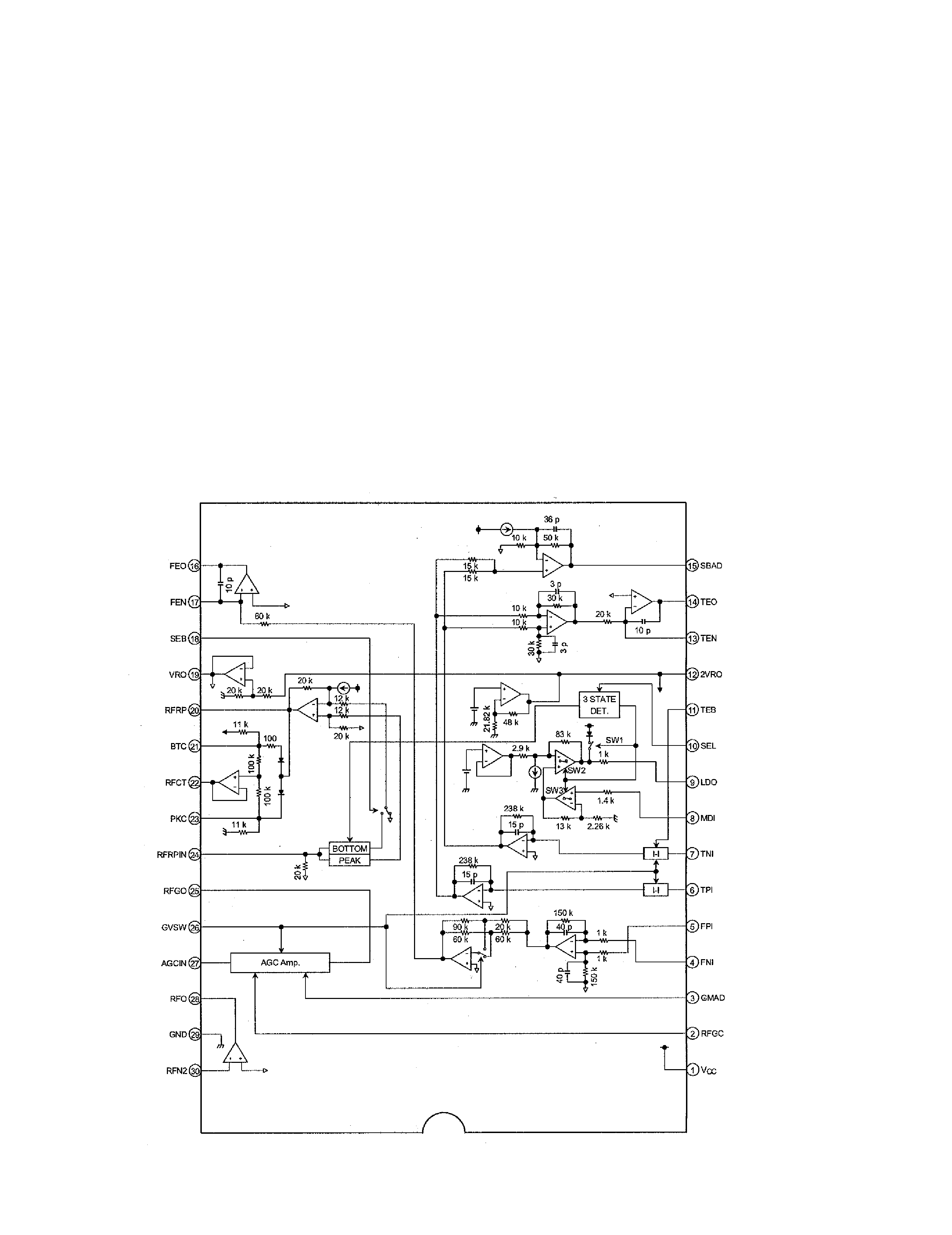

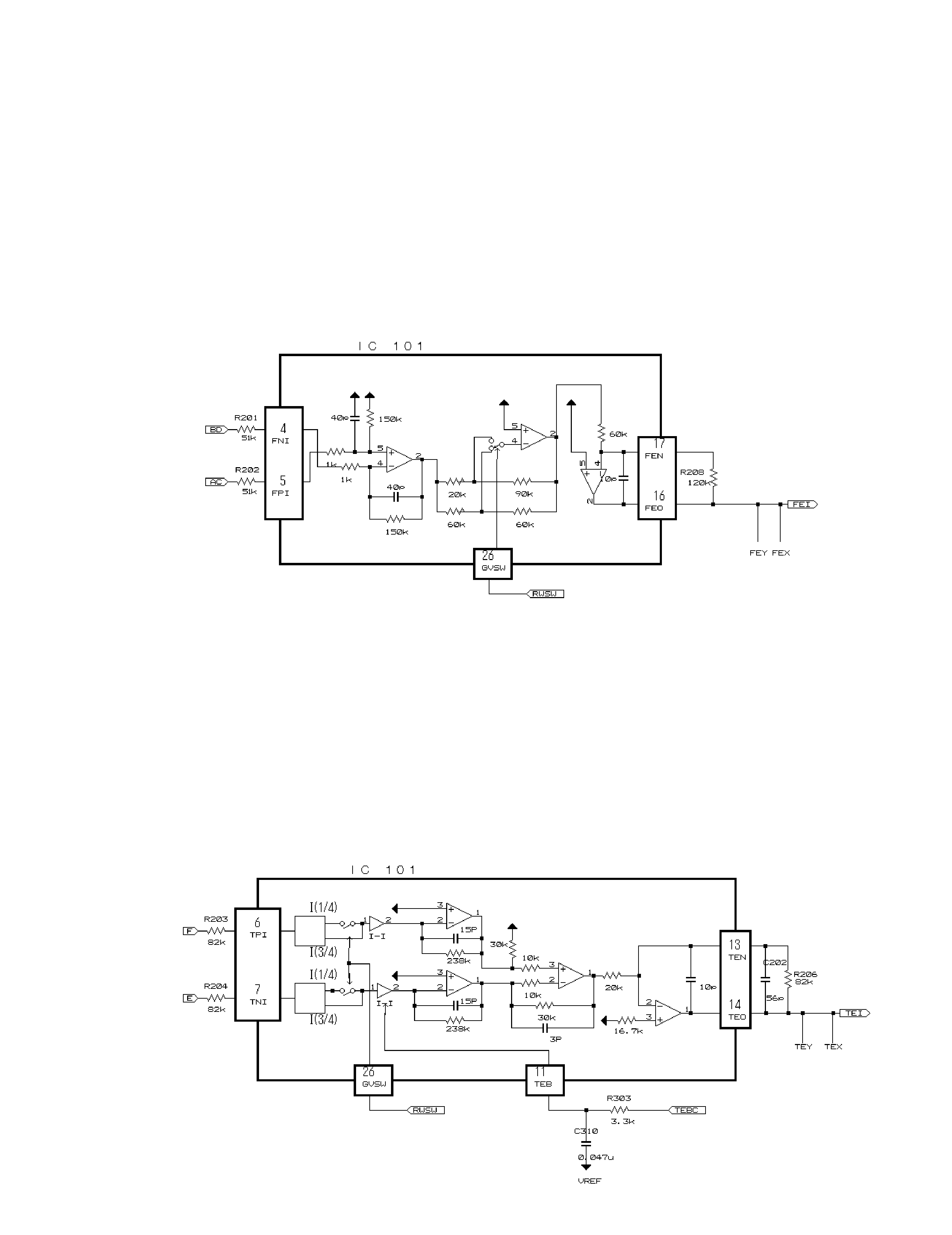

3) RF Amplifier unit

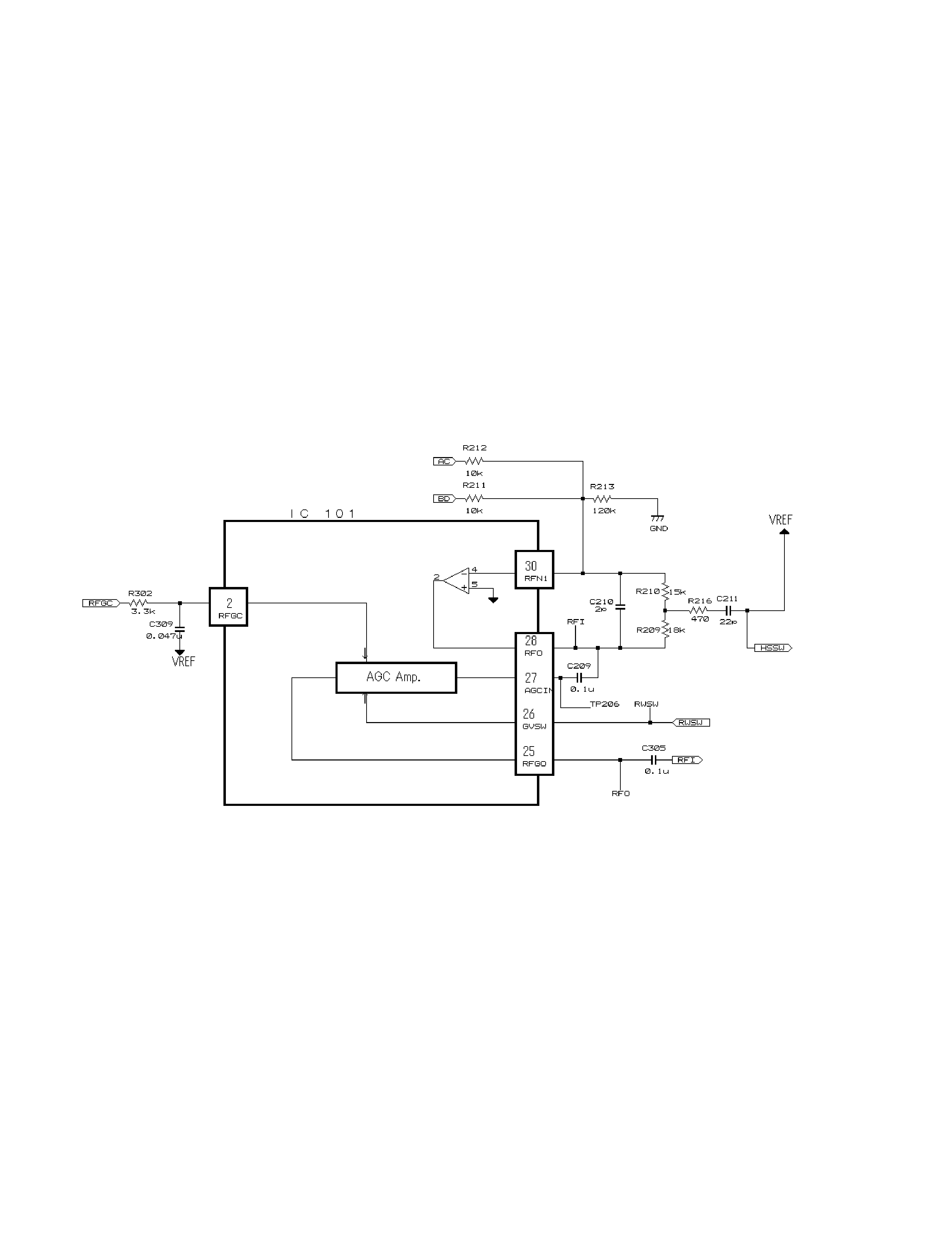

Outputs from the photo detector, namely, (A+C) and (B+D), are added up, amplified and equalized in the Head

Amplifier LSI (TA2153FN). The processed-signals are output to RFI terminal as RF signals (These signals are used to

check eye patterns).

Low frequency component of voltage RFI is expressed as:

RFI = (A+B+C+D) x 5.43

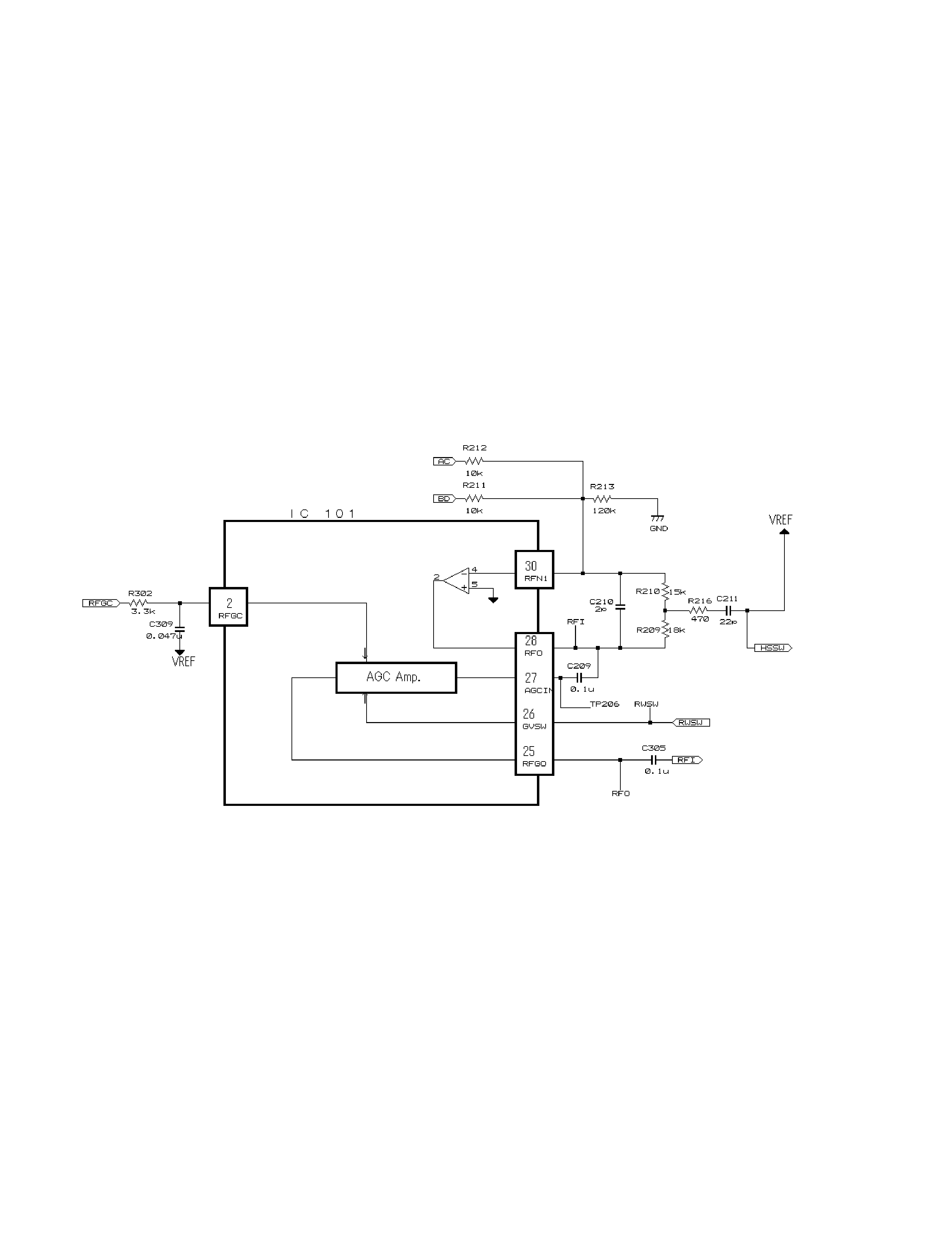

RFI is used for RF Offset Control circuit. These RFI signals so output from #28 pin are AC-coupled outside the unit, and

then re-input to #27 pin and amplified by the RFAGC amplifier to obtain RFO signals.

TA2153FN has built-in function for RFAGC adjustment, as described later, and through such function, the gain of

RFAGC is controlled so that RFO output stays within 1.2 ± 0.3 Vpp range.

Also, RFO signals are used for EFM and RFAGC Adjustment circuit. They are further used to generate RFRP and RFCT

signals, both of which are used for track counting.

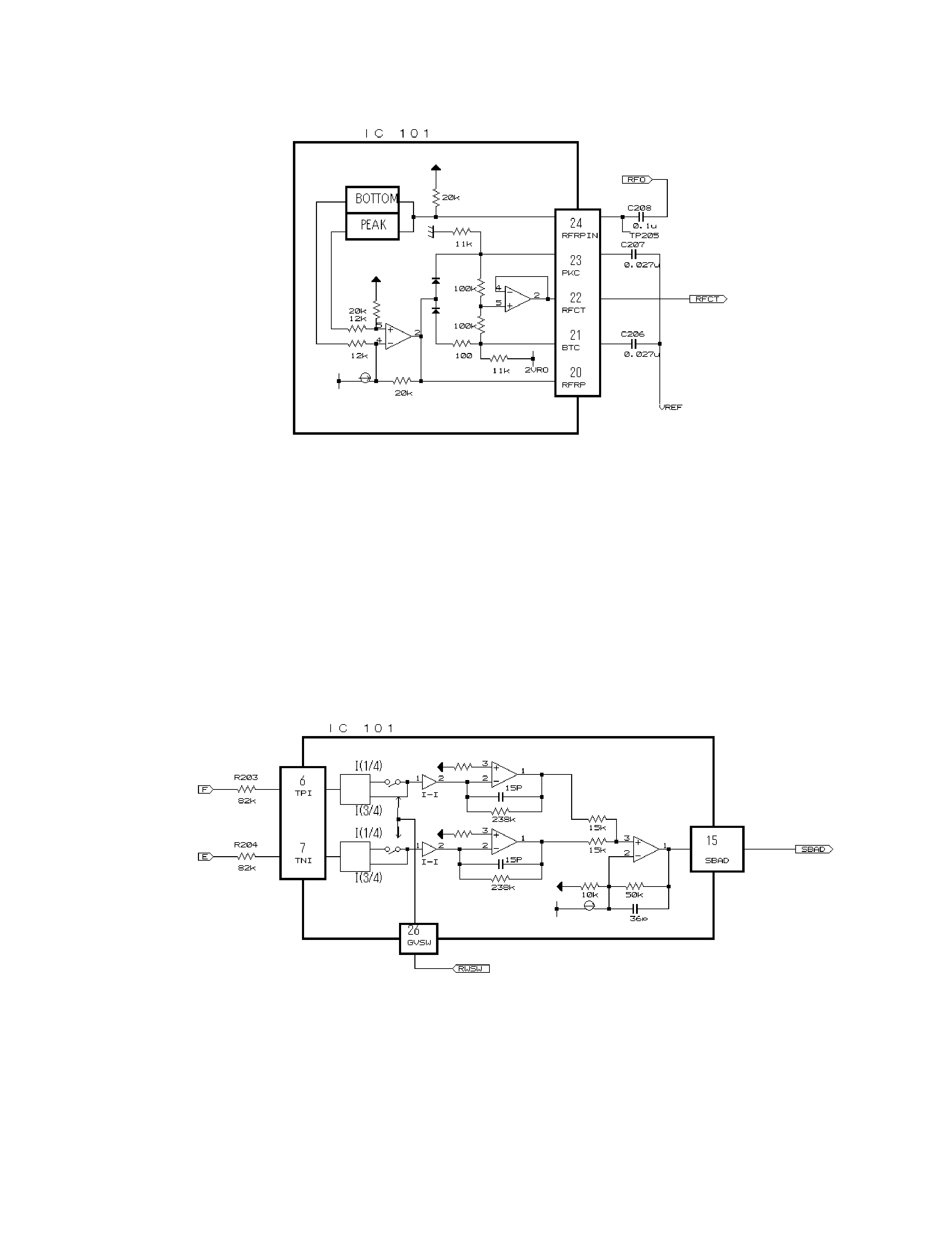

4) RFRP and RFCT Signal Circuit unit

RFCT signals are generated through the Head Amplifier (IC101). A RFCT signal is the difference signal that represents

the difference between the peak and bottom level of RF signal. RFRP and RFCT can be monitored at TP203 (#20 pin of

IC101, namely, TA2153FN) and TP204 (#20 pin of IC101) respectively.

Size-comparison among TE, RFRP and RFCT signals is performed by the Hysteresis Comparator in IC201 (TC9495F2),

and through such comparison, track information (TEZC and RFZC signal) is generated. Based on these signals,

information to determine tracking speed of the lens when it moves on the disk is generated. Also based on these

signals, number of tracks is counted.

Fig. 4: RF circuit