EFX-500

2

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 Proposition 65

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A PO-

TENTIAL SHOCK HAZARD AND MUST BE COR-

RECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appli-

ance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be ob-

tained by using replacement components rated for

voltage, wattage , etc.

Replacement parts which have

these special safety

characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the schematics and

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or

ad-

ditional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

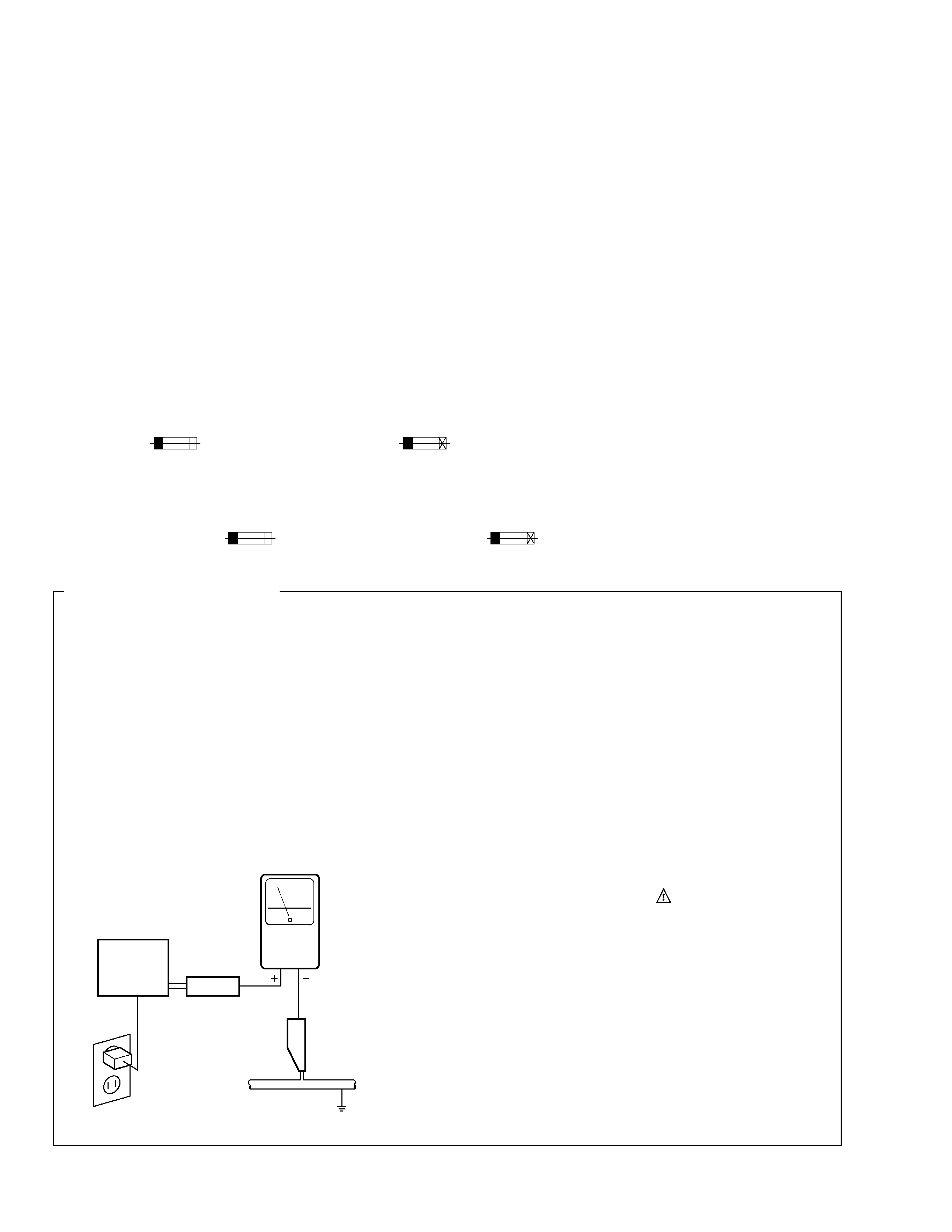

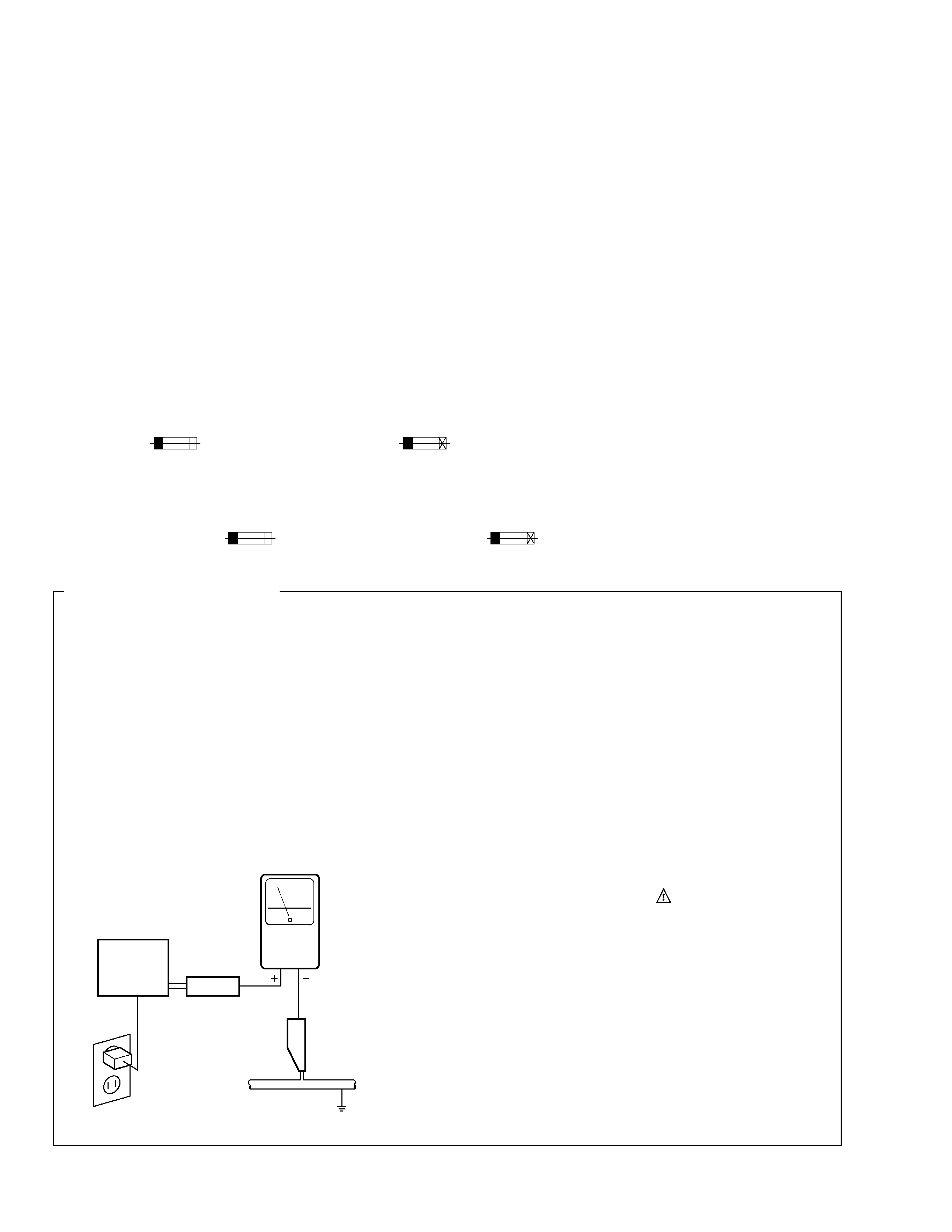

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

(FOR USA MODEL ONLY)

Also test with plug

reversed

(Using AC adapter

plug as required)

Device

under

test

Test all exposed

metal surfaces

Earth ground

Leakage

current

tester

Reading should

not be above

0.5 mA

AC Leakage Test

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

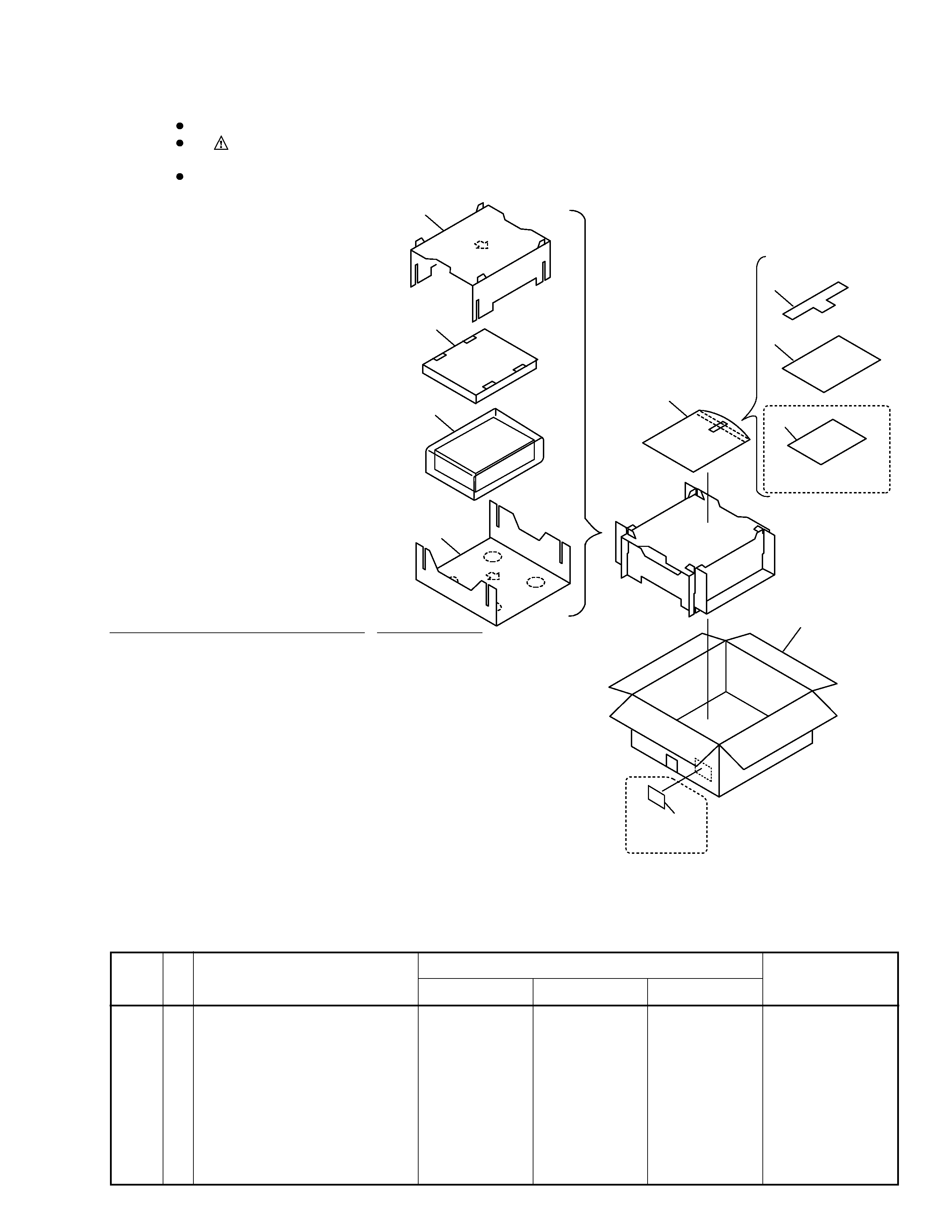

Les symboles de fusible

(fusible de type rapide) et/ou

(fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols

(fast operating fuse) and/or

(slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.