DVR-RT501-S

4

12

34

12

3

4

C

D

F

A

B

E

CONTENTS

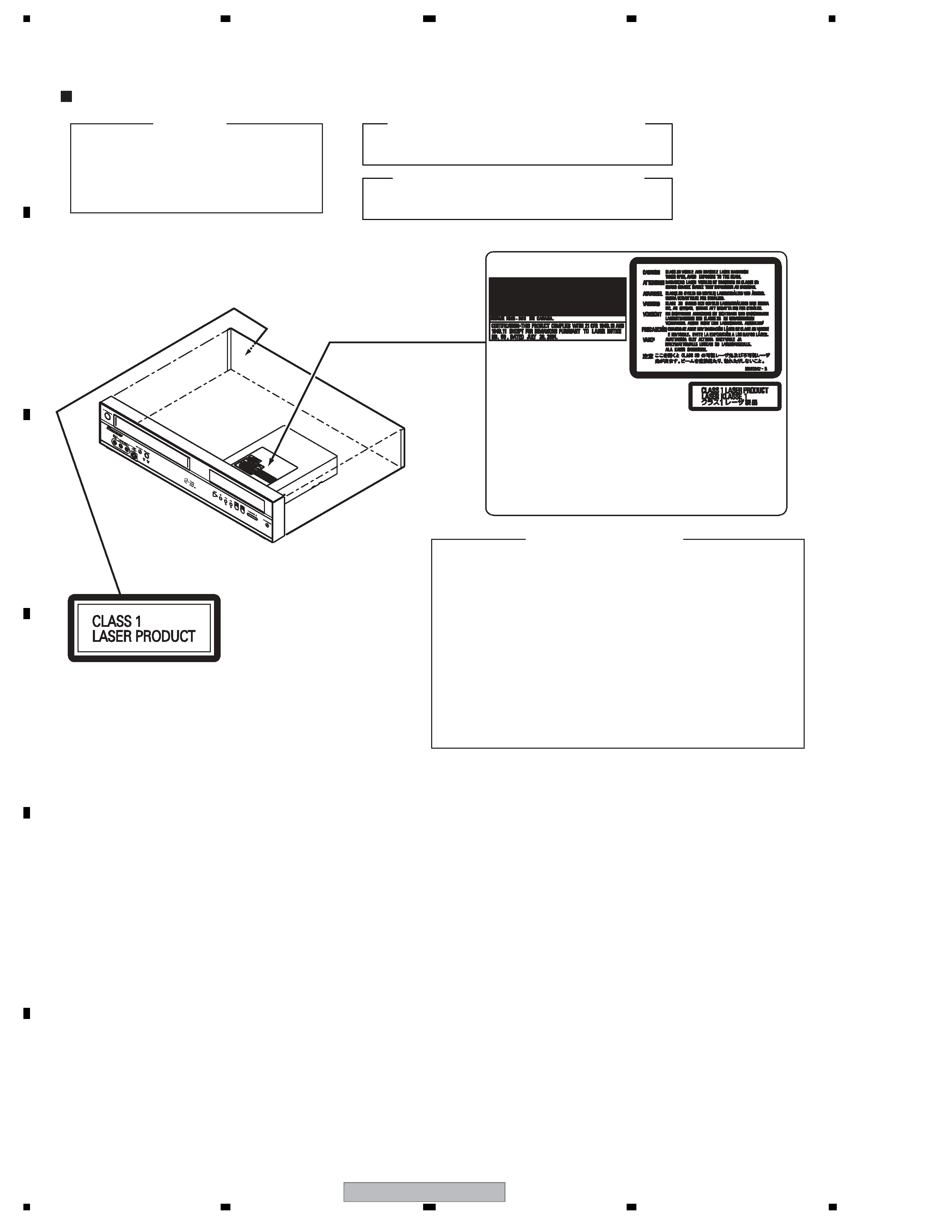

SAFETY INFORMATION ..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 6

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 8

2.1 PACKING ................................................................................................................................................... 8

2.2 EXTERIOR SECTION.............................................................................................................................. 10

2.3 DECK ASSY (TOP SECTION) ................................................................................................................. 12

2.4 DECK ASSY (BOTTOM SECTION) ......................................................................................................... 14

2.5 WIRING CABLE ....................................................................................................................................... 16

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................18

3.1 BLOCK DIAGRAM ................................................................................................................................... 18

3.1.1 OVERALL BLOCK DIAGRAM............................................................................................................ 18

3.1.2 MPEG BLOCK BLOCK DIAGRAM .................................................................................................... 19

3.1.3 Y/C AUDIO / HEAD AMP BLOCK DIAGRAM.....................................................................................20

3.1.4 SYSTEM CONTROL BLOCK DIAGRAM ...........................................................................................21

3.1.5 REGULATOR BLOCK DIAGRAM ...................................................................................................... 22

3.1.6 OPERATION / DISPLAY BLOCK DIAGRAM......................................................................................23

3.1.7 AV IN/OUT/TUNER/HiFi BLOCK DIAGRAM...................................................................................... 24

3.1.8 21PIN IN/OUT BLOCK DIAGRAM ..................................................................................................... 25

3.1.9 POWER BLOCK DIAGRAM............................................................................................................... 26

3.2 OVERALL WIRING DIAGRAM................................................................................................................. 28

3.3 DVD/HD MPEG PCB ASSY(1/6).............................................................................................................. 30

3.4 DVD/HD MPEG PCB ASSY(2/6).............................................................................................................. 32

3.5 DVD/HD MPEG PCB ASSY(3/6).............................................................................................................. 34

3.6 DVD/HD MPEG PCB ASSY(4/6).............................................................................................................. 36

3.7 DVD/HD MPEG PCB ASSY(5/6).............................................................................................................. 38

3.8 DVD/HD MPEG PCB ASSY(6/6).............................................................................................................. 40

3.9 VCR MT PCB ASSY(1/7) ......................................................................................................................... 42

3.10 VCR MT PCB ASSY(2/7) ....................................................................................................................... 44

3.11 VCR MT PCB ASSY(3/7) ....................................................................................................................... 46

3.12 VCR MT PCB ASSY(4/7) ....................................................................................................................... 48

3.13 VCR MT PCB ASSY(5/7) ....................................................................................................................... 50

3.14 VCR MT PCB ASSY(6/7) ....................................................................................................................... 52

3.15 VCR MT PCB ASSY(7/7) ....................................................................................................................... 54

3.16 POWER PCB ASSY............................................................................................................................... 56

3.17 OPERATION 1, 2 and 3 PCB ASSYS .................................................................................................... 58

3.18 WAVE FORMS ....................................................................................................................................... 60

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 65

4.1 DVD/HD MPEG PCB ASSY ..................................................................................................................... 66

4.2 VCR MT PCB ASSY ................................................................................................................................ 70

4.3 POWER PCB ASSY................................................................................................................................. 74

4.4 OPERATION 1, 2 and 3 PCB ASSYS ...................................................................................................... 75

5. PCB PARTS LIST ........................................................................................................................................... 76

6. ADJUSTMENT ............................................................................................................................................... 79

6.1 SERVICE MODE LIST ............................................................................................................................. 79

6.2 ADJUSTMENT ITEMS AND NECESSARY ADJUSTMENT POINTS...................................................... 80

6.3 SERVICING FIXTURES AND TOOLS ..................................................................................................... 81

6.4 CONFIRMATION OF HOURS USED....................................................................................................... 82

6.5 PREVENTIVE CHECKS AND SERVICE INTERVALS............................................................................. 83

6.6 MECHANICAL ADJUSTMENTS .............................................................................................................. 84

6.7 ELECTRICAL ADJUSTMENTS ............................................................................................................... 88

6.8 WHEN REPLACING NEW DVD LOADER ...............................................................................................90

6.9 WHEN REPLACING EEPROM (MEMORY) IC ........................................................................................ 91

7. GENERAL INFORMATION ............................................................................................................................. 93

7.1 RE-WRITE FOR DVD FIRMWARE .......................................................................................................... 93

7.2 RE-WRITE FOR DRIVE FIRMWARE ...................................................................................................... 93

7.3 MEASUREMENT OF ERROR RATE ....................................................................................................... 94

7.4 ERROR CODE LIST ................................................................................................................................ 95

7.5 POWER ON SEQUENCE ...................................................................................................................... 100

7.6 DISC REMOVAL METHOD.................................................................................................................... 101

7.7 TAPE REMOVAL METHOD AT NO POWER SUPPLY........................................................................... 101

7.8 PARENTAL CONTROL-RATING LEVEL ................................................................................................ 102

7.9 TRAY LOCK ........................................................................................................................................... 102

7.10 DISASSEMBLY .................................................................................................................................... 103

7.11 CAUTIONS ON DIASSEMBLING AND ASSEMBLING ....................................................................... 111

7.12 IC ......................................................................................................................................................... 113