DVD-V5000

4

12

34

12

3

4

C

D

F

A

B

E

CONTENTS

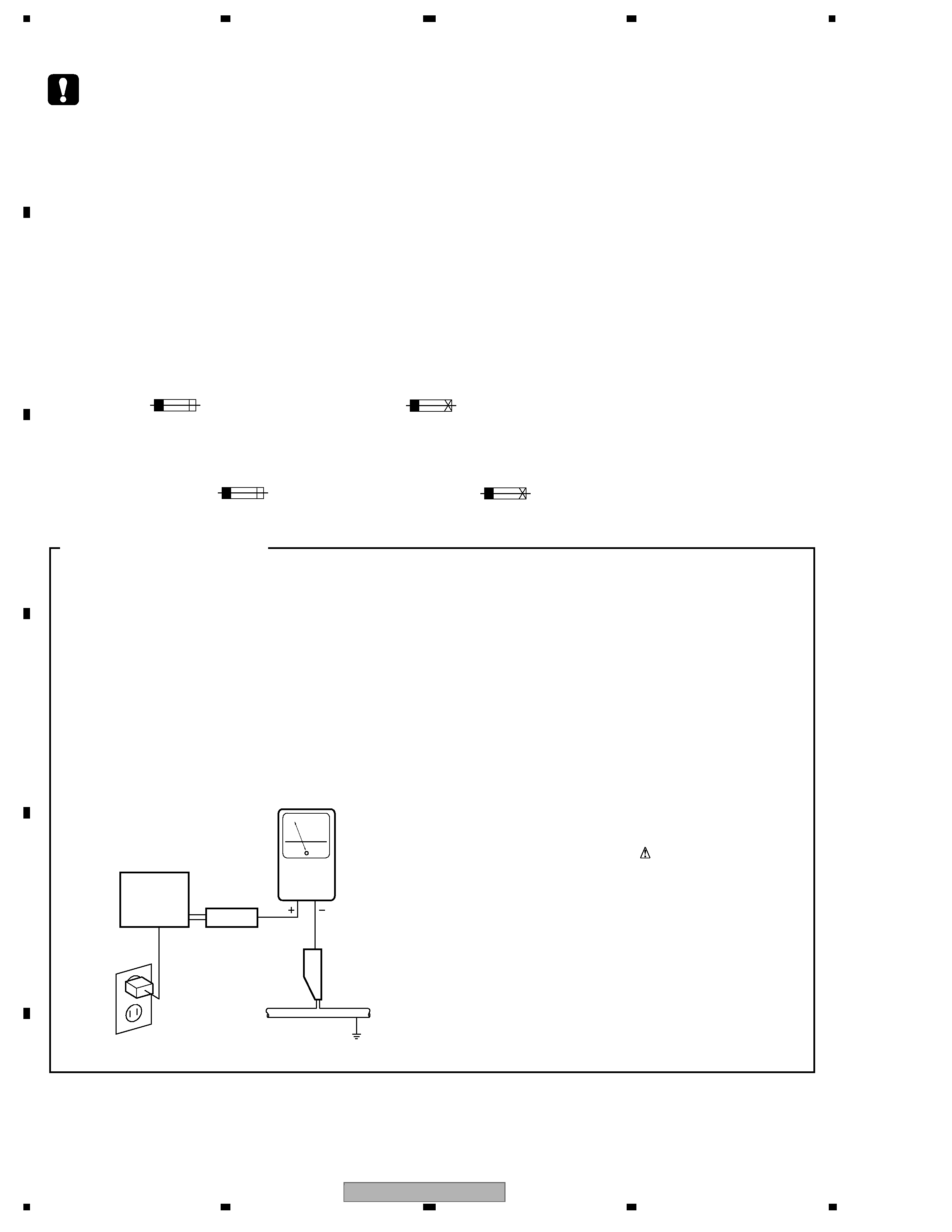

SAFETY INFORMATION ..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 FRONT PANEL SECTION ....................................................................................................................... 10

2.4 LOADING MECHA. ASSY ....................................................................................................................... 12

2.5 TRAVERSE MECHA. ASSY-S ................................................................................................................. 14

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................16

3.1 BLOCK DIAGRAM ................................................................................................................................... 16

3.1.1 SIGNAL ROUTE ................................................................................................................................ 16

3.1.2 POWER SUPPLY and CLOCK SECTION ......................................................................................... 18

3.2 OVERALL WIRING DIAGRAM and LOAB ASSY..................................................................................... 20

3.3 MAIN ASSY (1/4) ..................................................................................................................................... 22

3.4 MAIN ASSY (2/4) ..................................................................................................................................... 24

3.5 MAIN ASSY (3/4) ..................................................................................................................................... 26

3.6 MAIN ASSY (4/4) ..................................................................................................................................... 28

3.7 JCKB ASSY ............................................................................................................................................. 30

3.8 SUBB ASSY............................................................................................................................................. 32

3.9 FLKY and PWSB ASSYS ........................................................................................................................ 34

3.10 WAVEFORMS ........................................................................................................................................ 36

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 37

4.1 LOAB ASSY ............................................................................................................................................. 37

4.2 MAIN ASSY ............................................................................................................................................. 38

4.3 JCKB and SUBB ASSYS ......................................................................................................................... 42

4.4 FLKB and PWSB ASSYS ........................................................................................................................ 46

5. PCB PARTS LIST ........................................................................................................................................... 48

6. ADJUSTMENT ............................................................................................................................................... 51

6.1 ADJUSTMENT ITEMS AND LOCATION ................................................................................................. 51

6.2 TEST MODE ............................................................................................................................................ 52

6.3 MECHANISM ADJUSTMENT .................................................................................................................. 53

7. GENERAL INFORMATION ............................................................................................................................. 55

7.1 DIAGNOSIS ............................................................................................................................................. 55

7.1.1 TEST MODE ...................................................................................................................................... 55

7.1.2 SELF-DIAGNOSIS FUNCTION OF PICKUP DEFECTIVE ............................................................... 57

7.1.3 TEST MODE SCREEN DISPLAY ...................................................................................................... 58

7.1.4 SPECIAL COMMANDS FOR DEBUGGING...................................................................................... 60

7.1.5 RS-232C LOOP TESTS .................................................................................................................... 62

7.1.6 ERROR LOG ..................................................................................................................................... 63

7.1.7 SELF-DIAGNOSIS............................................................................................................................. 65

7.1.8 HOUR METER................................................................................................................................... 66

7.1.9 EXTERNAL TERMINAL TEST MODE ...............................................................................................67

7.1.10 TEST MODE FOR THE KEYS AND LEDS ON THE MAIN UNIT .................................................... 68

7.1.11 ID NUMBER AND ID DATA SETTING ............................................................................................. 69

7.1.12 TROUBLE SHOOTING .................................................................................................................... 72

7.1.13 DISASSEMBLY................................................................................................................................ 73

7.1.14 UPDATING THE FIRMWARE .......................................................................................................... 82

7.2 IC ............................................................................................................................................................. 83

7.3 DISC / CONTENT FORMAT PLAYBACK COMPATIBILITY ................................................................... 110

7.4 CLEANING............................................................................................................................................. 111

8. PANEL FACILITIES ...................................................................................................................................... 112