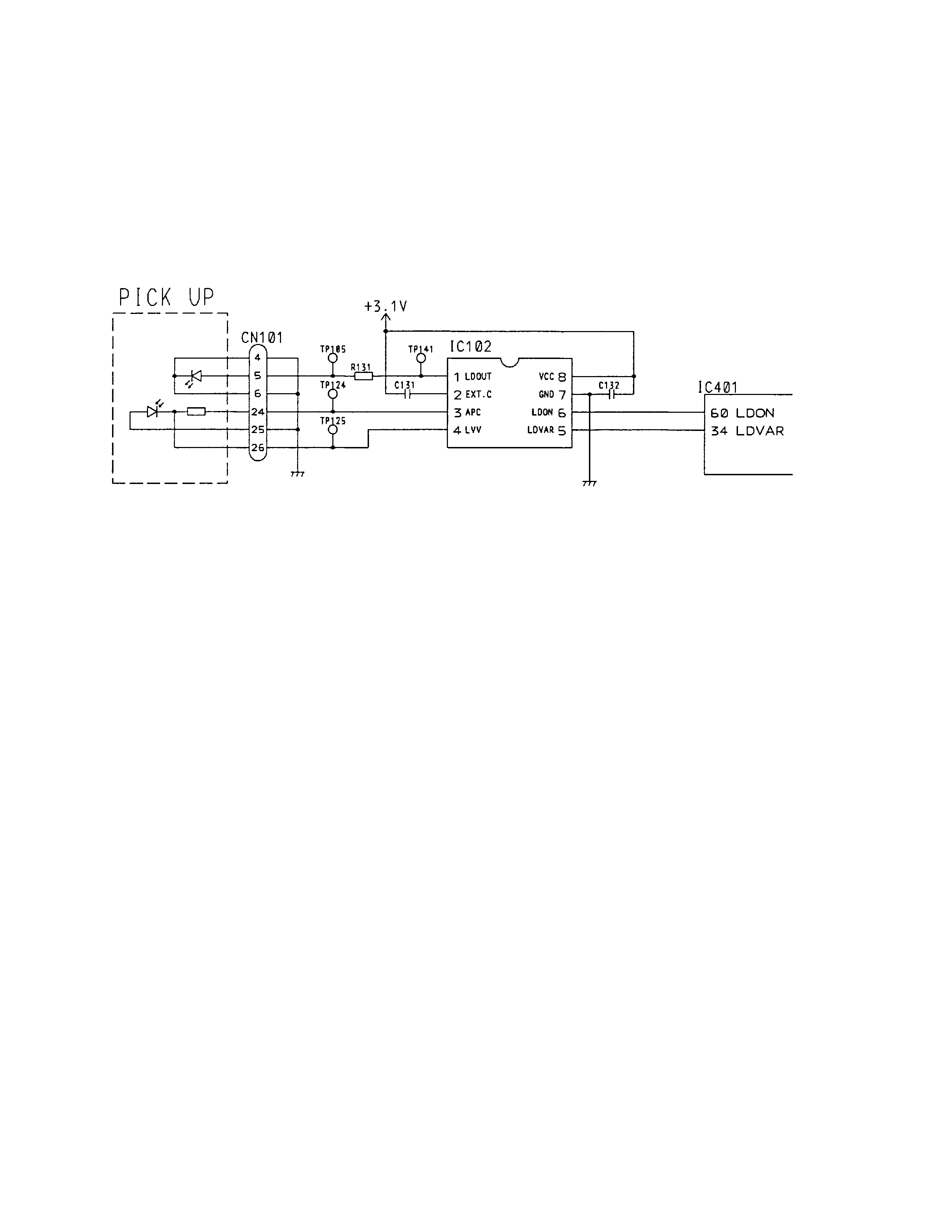

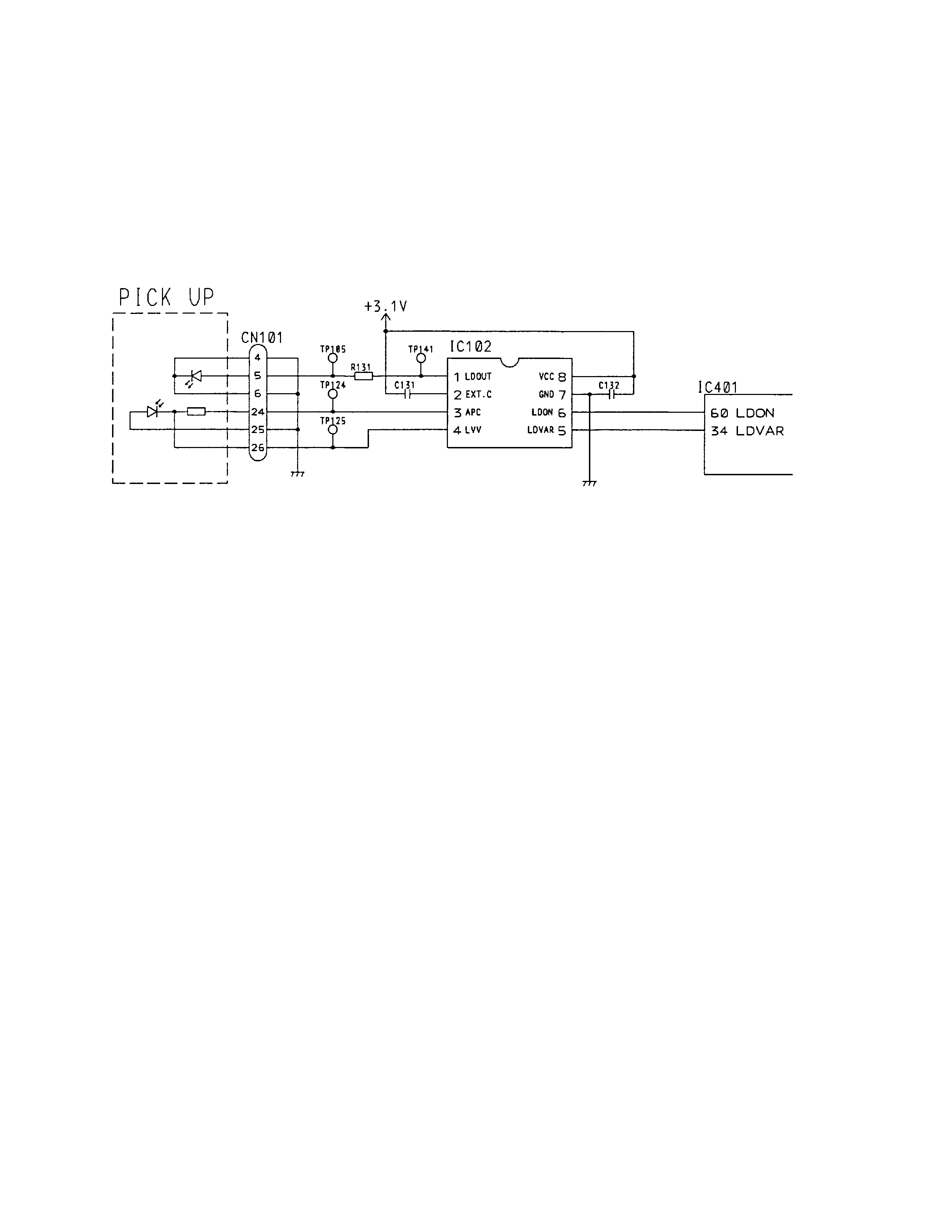

Figure 1 below shows the block diagram. This block

controls the output from the block LD to be consistent

with the monitor diode.

The block consists of IC 102 and turned to LD ON when

LDON (6 pin) is H and to LD OFF when LDON is L. LD

output level is set with the voltage value of LDVAR and

is usually around 2.4 V.

2

CX-893

1. CIRCUIT DESCRIPTION

1.1 APC Part

Fig.1

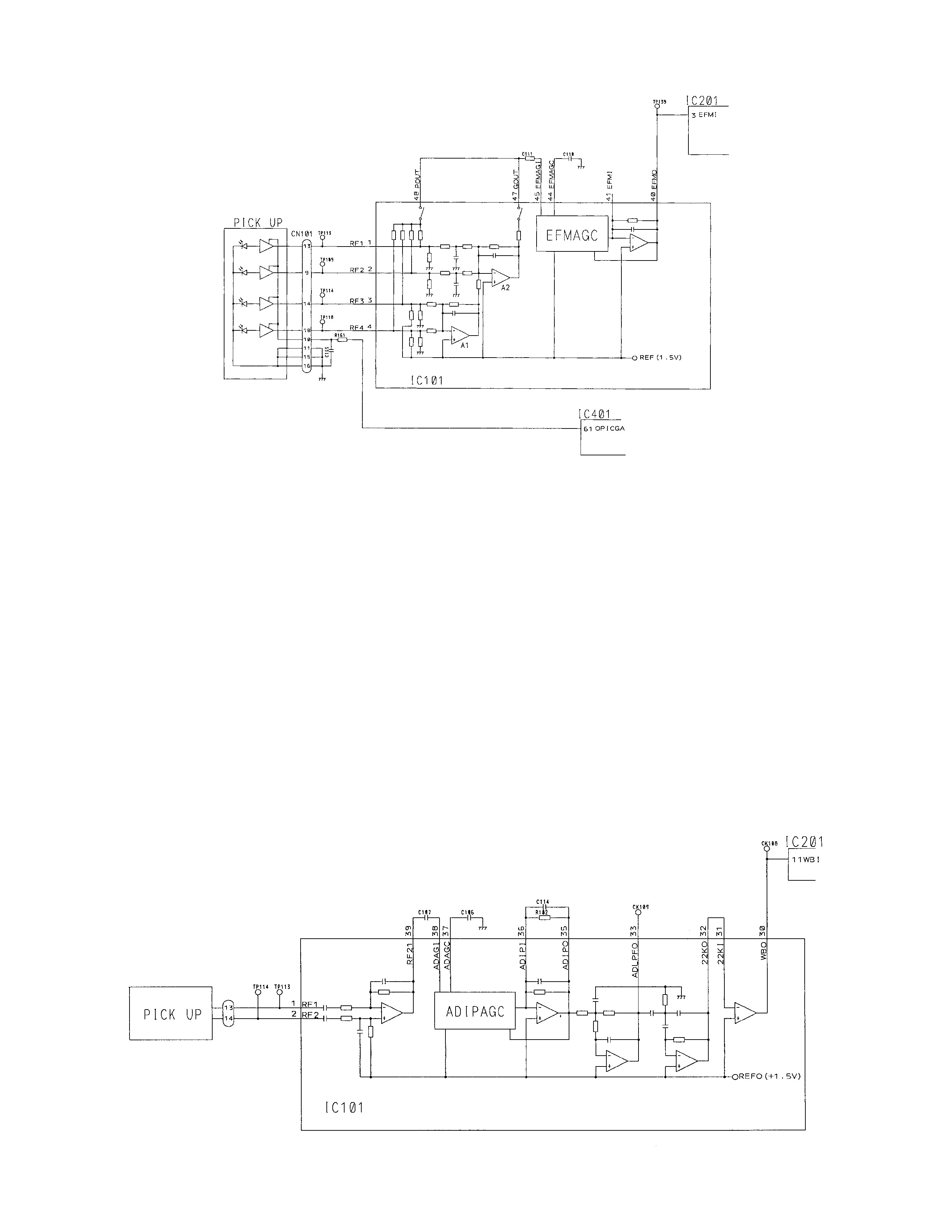

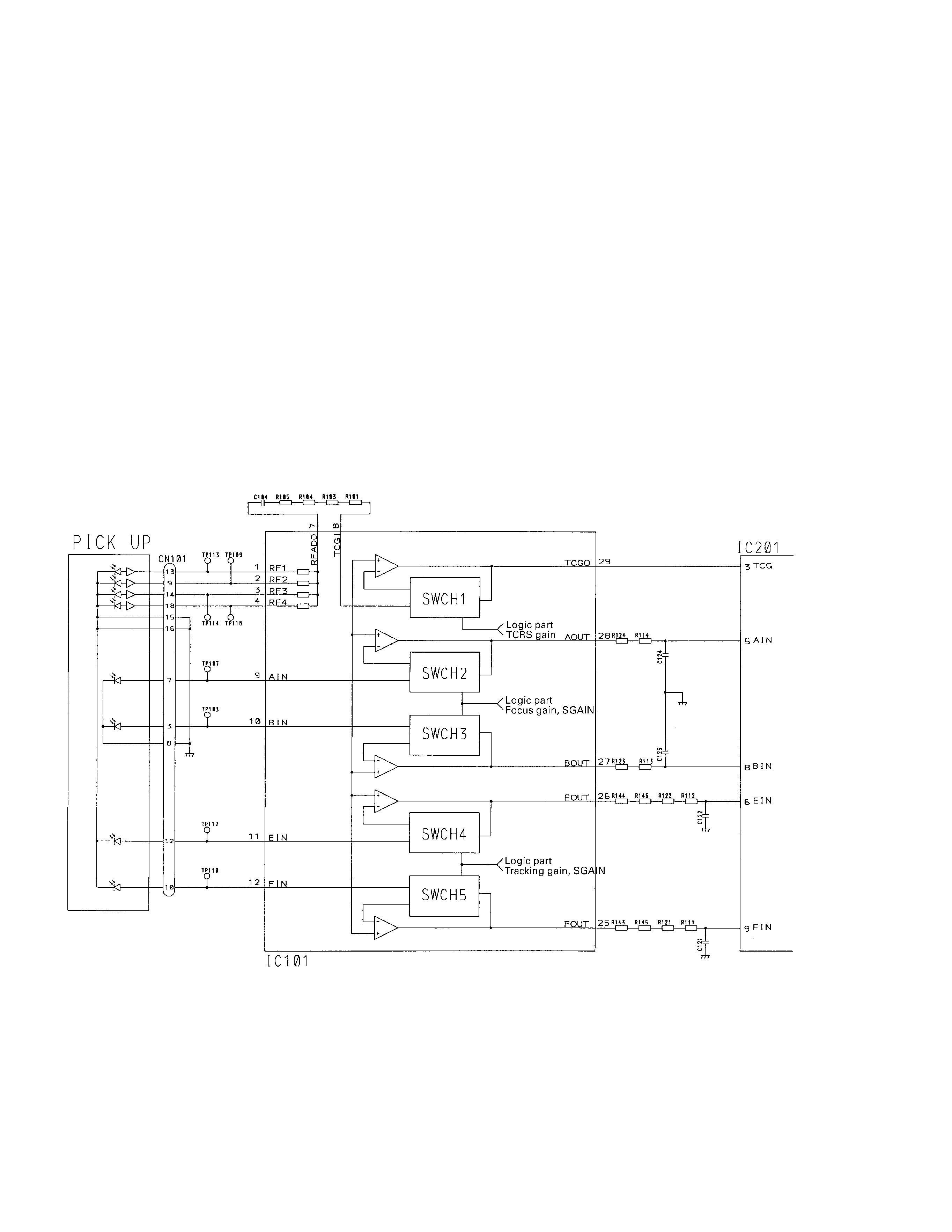

1.2 RF amplifying part

The block amplifies the pickup output signal and

generates RF and ADIP signals.

This block mainly consists of IC101.

REFO part

REFO (+1.5 V) is the reference voltage for the servo.

The signal is resistive divided at the IC (REFI: 5 pin) and

output to 6 pin through buffer. This signal will be the

reference for RFIC.

RF signal amplifying part

Figure 2 below shows the block diagram. The signal

which is I-V converted at the pickup is input to the RF1-4

(1-4 pin). Gain at the I-V amplifier contained in the PU

is switched depending on the disc types. The switching

is controlled by OPICGA (IC401, 61 pin) and H is output

at Premaster DISC and L is output at Recordable DISC.

The signal input from the I-V amplifier is operated with

the contained resistance and amplifiers (A1, A2) and the

signal (RF1 + RF2 + RF3 + RF4) (POUT) and the signal

(RF1 + RF2 + RF3 - RF4) (GOUT) are generated. Each of

POUT and GOUT is equipped with an analog switch.

The switches are controlled with the DISC signal (bits

on microprocessor serial communications). The POUT

signal is output through 48 pin when the DISC signal is

H (PIT mode) and GOUT signal is output through 47 pin

when the DISC signal is L (GRV mode).

These signals are input to EFMAGC (45 pin) through the

coupling capacitors (C133, C112) and transmitted to the

AGC circuit and filter part to be output from EFMO (40

pin). The EFMO is maintained at almost same level

(approx. 1.5 Vpp) with the AGC circuit. These signals

are input to the signal processing part (IC201: 3 pin) and

used for data processing and spindle control when

playing a Premaster Disc.