4

CX-890

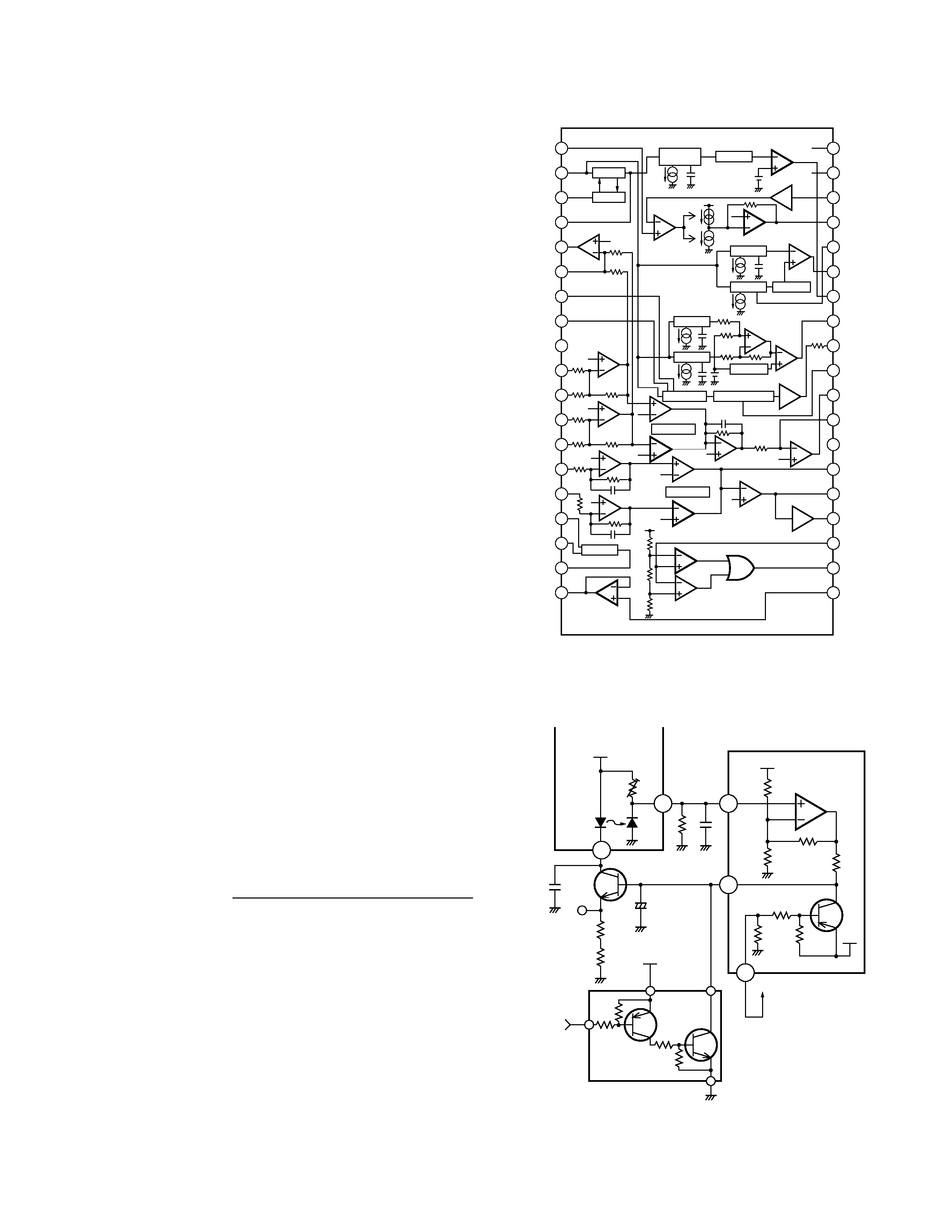

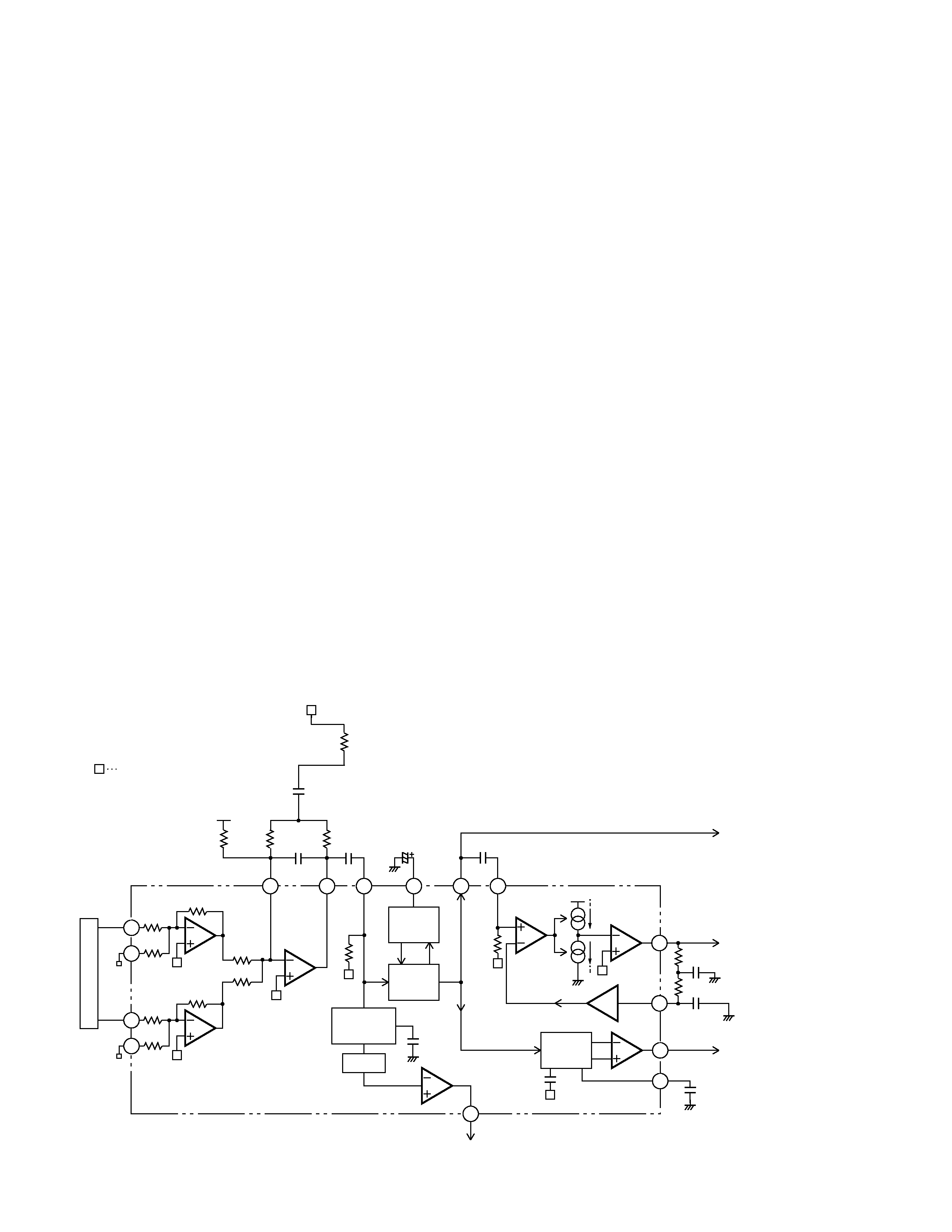

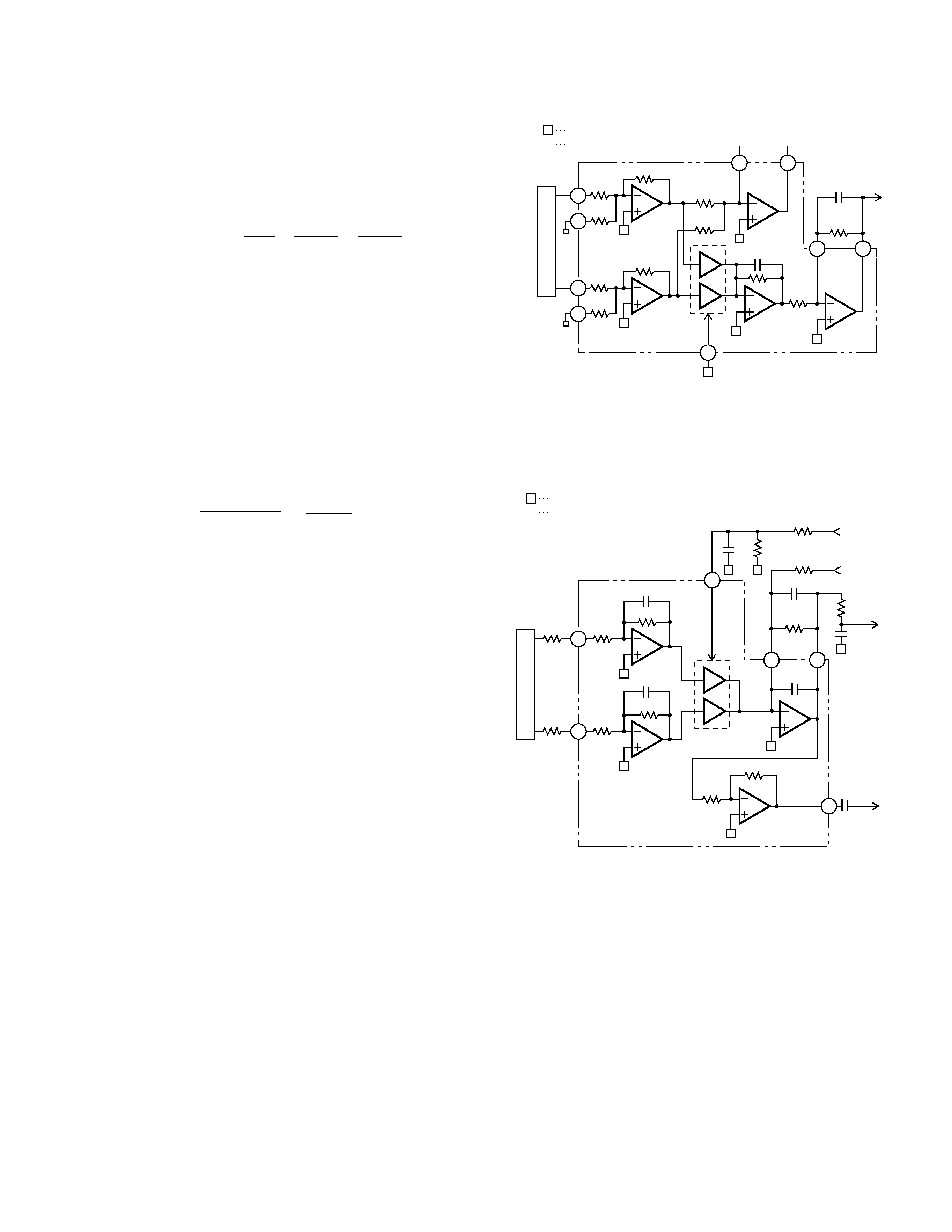

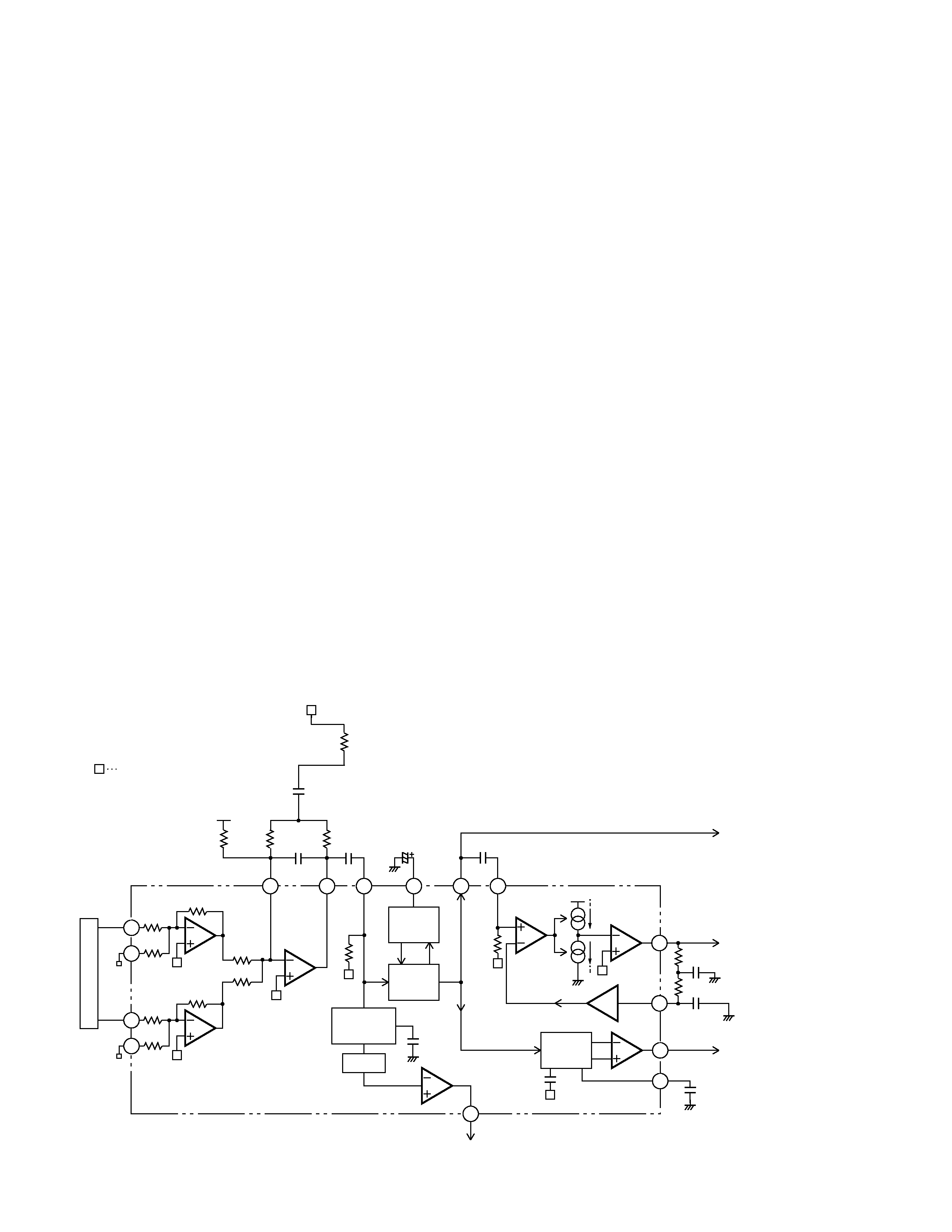

2) RF amplifier and RF AGC amplifier

Photodetector outputs (A+C) and (B+D) are added,

amplified and equalized in IC101, and output to the RFI

terminal as RF signal. (Eye pattern can be checked at

this terminal.)

Low-frequency components of voltage RFI is:

RFI = ((A + C) + (B + D)) x 3.22

where R111 is offset resistor to keep RFI signal within

the output range of the preamplifier. RFI signal is goes

under AC coupling, and is input to Pin 4 (RFIN termi-

nal).

IC101 contains an RF AGC circuit. RFO output from Pin

2 is maintained to a constant level (1.2 ±0.2 Vp-p). The

RFO signal is used in the EFM, DFCT, and MIRR circuits.

3) EFM circuit

The EFM circuit converts RF signal into digital signals of

"0" and "1". RFO signal after AC coupling is input to Pin

1, and supplied to the EFM circuit.

Asymmetry caused during manufacturing of discs can-

not be eliminated solely by AC coupling. Therefore, the

system controls the reference voltage ASY of the EFM

comparator by using the fact that probability to gener-

ate "0" and "1" is 50% in EFM signal. This reference volt-

age ASY is generated by output from the EFM com-

parator through L.P.F. EFM signal is output from Pin 35.

As signal level, amplification is 2.5 Vp-p around

REFOUT.

4) DFCT (defect) circuit

DFCT signal detects mirror defect in discs, and is output

from Pin 33. The system outputs "H" when a mirror

defect is detected.

If disc is soiled, the system determines it as lack of mir-

ror. Therefore, the system inputs the DFCT signal out-

put to the HOLD terminal of servo LSI. Focus and track-

ing servo drives change to Hold status only when DFCT

output is in "H" so that performance of the system upon

detection of defect can be improved.

5) RFOK circuit

The RFOK circuit outputs signal to show the timing of

focus closing servo, as well as the status of focus clos-

ing during playback. The signal is output from Pin 32.

The system inputs the RFOK signal output to the RFOK

terminal of servo LSI. The servo LSI issues Focus Close

command. The system outputs signal in "H" during

focus closing and playback.

CN101

13

6

DETECT

13

11

10

10k

20k

9.3k

RFI

+5V

R111

27k

Vcc

×12

ASY

12

20k

(RF AGC)

AGC

RF

ENVELOPE

HPF

VDC

RFOK

20k

33

36

35

34

PEAK

DEFECT

EFM

UPC2572GS

A+C

10k

B+D

9.3k

20k

10k

10k

R105

6.8k

C125 5pF

C105

24pF

R125

0R0

R104

8.2k

RFIN

C107

4.7

µF/35V

C122

0.1

µF

C106

RFO

REFOUT (+2.5V)

DEFECT

BOTTOM

R107 8.2k

R106 18k

C111 3300pF

C110

C112 0.047

µF

6

54

3

21

32

0.1

µF

2200pF

HOLD

Fig. 3 RF AMP, RF AGC, EFM, DFCT, RFOK Circuit