KDC-C715/Y

5

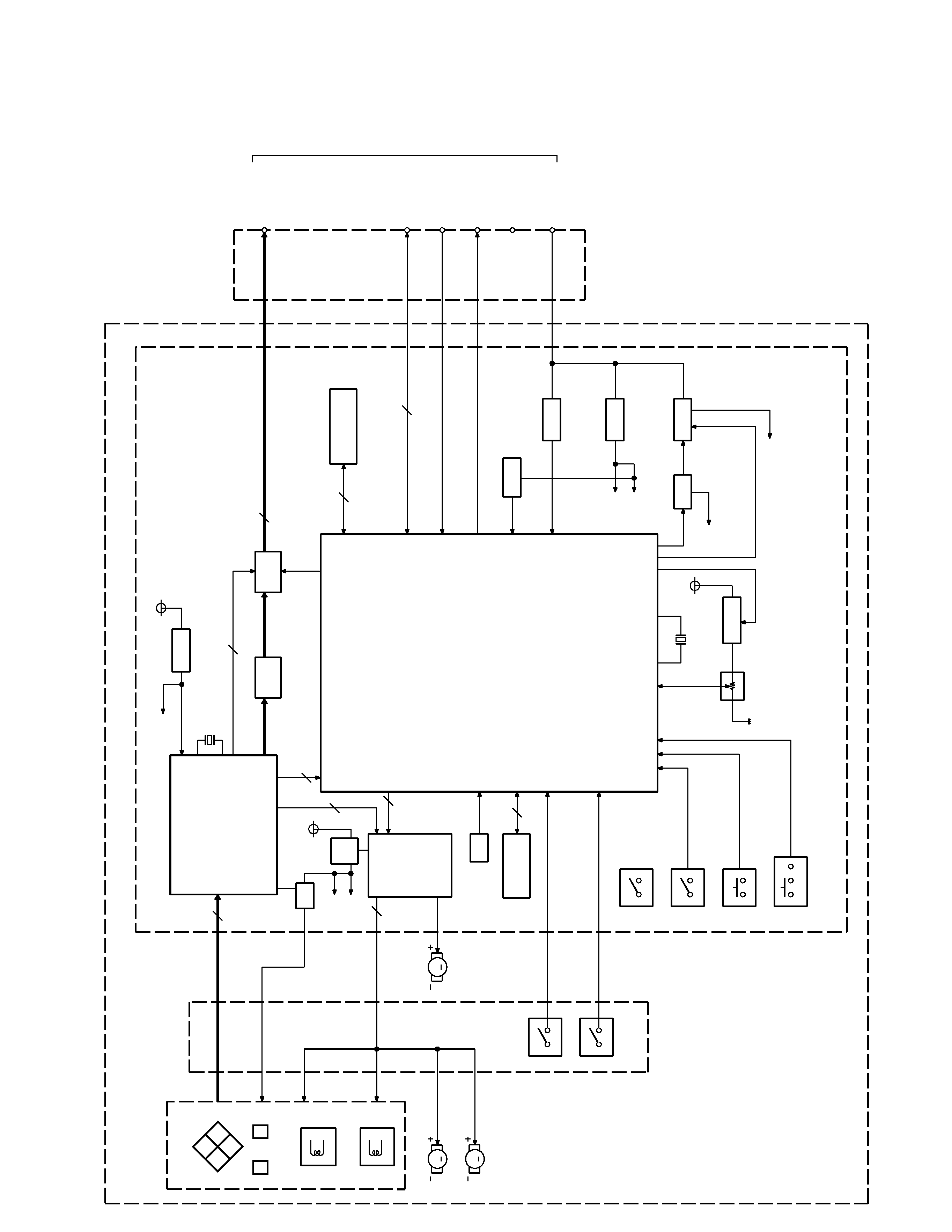

ADJUSTMENT

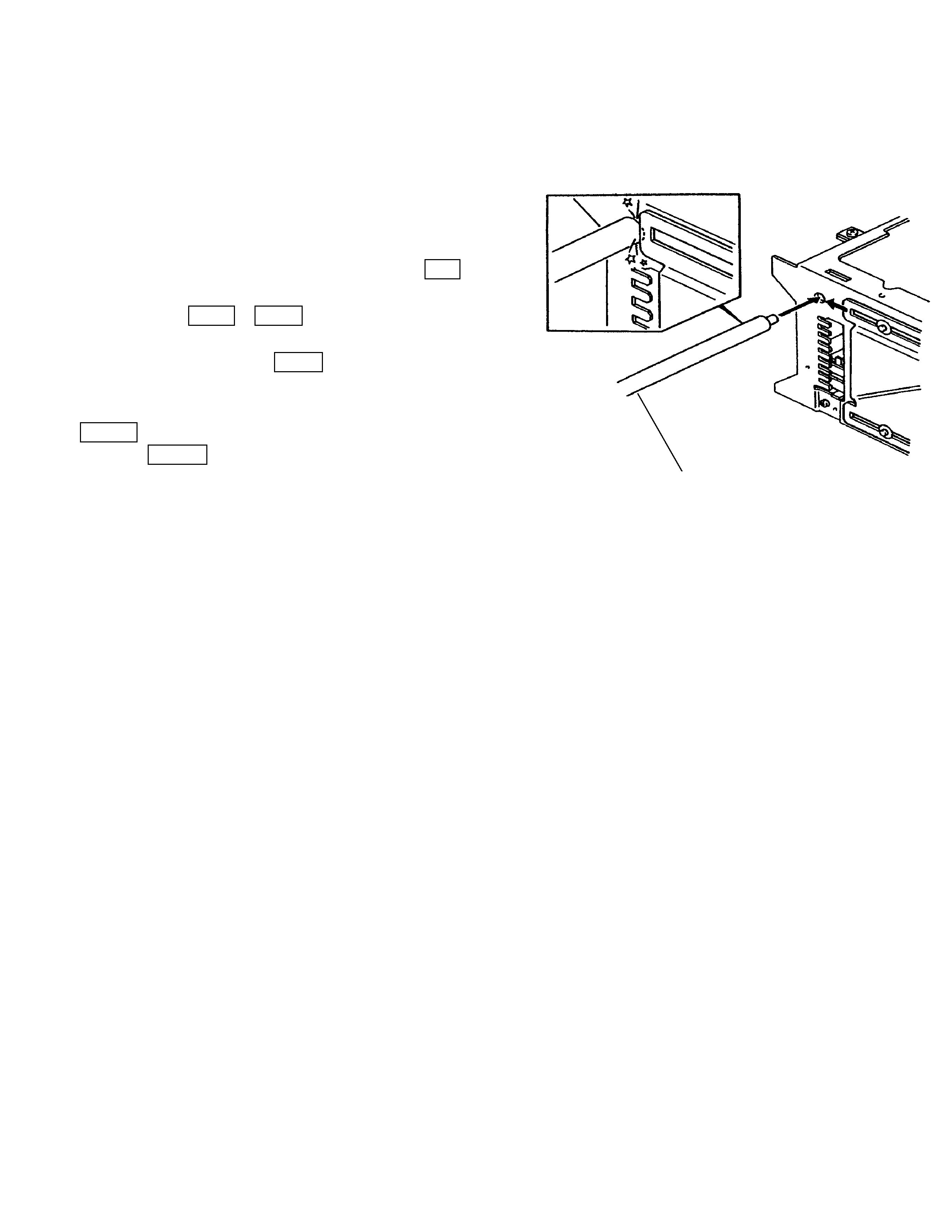

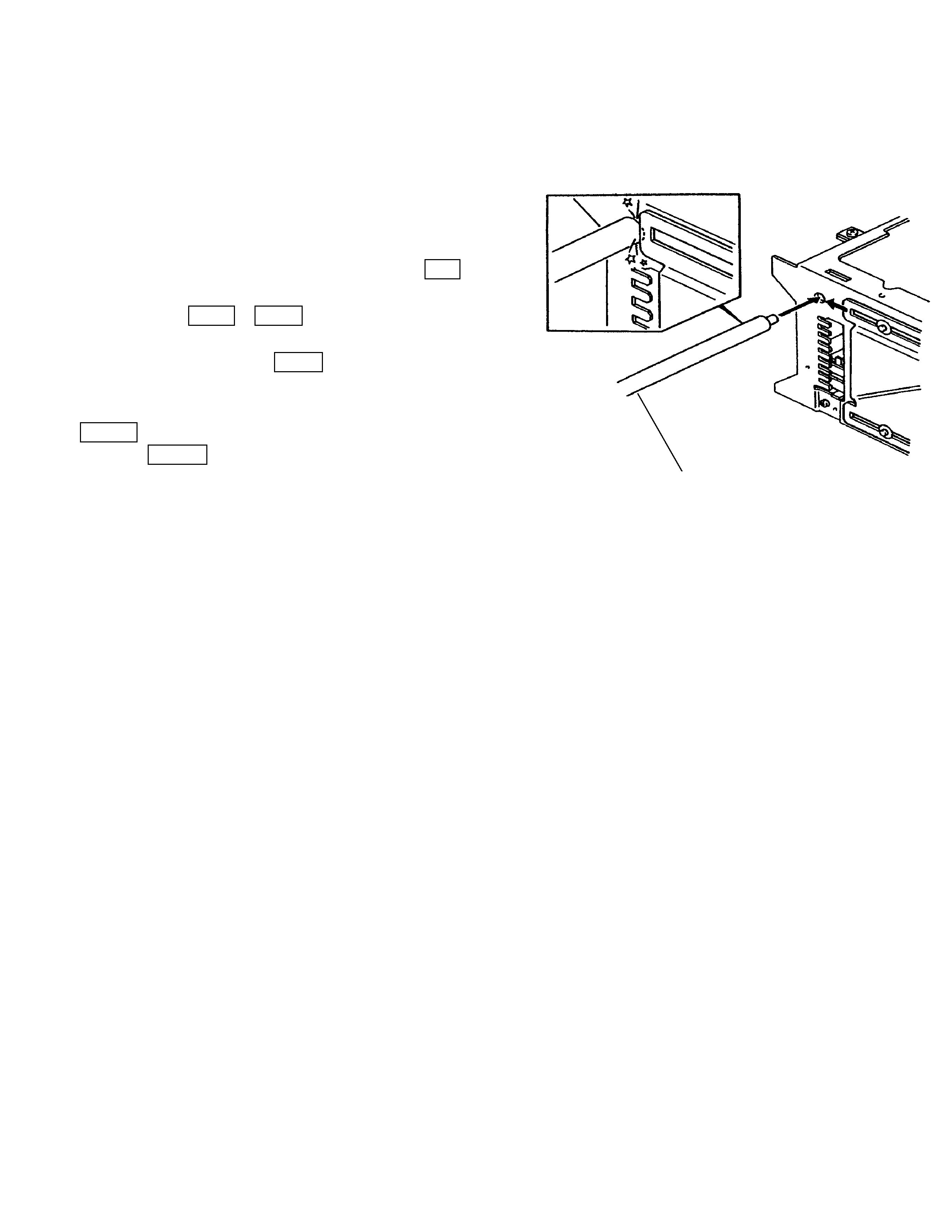

LPS initial position adjustment procedure

Connect the changer to the H/U. While holding the maga-

zine eject button of the changer, press the reset button of

the H/U and, in about 1 second, release the magazine eject

button. Press the CD button of the H/U to enter the E-88

mode. Move the mechanism deck to around the 1st stage

by pressing the DISC- or DISC+ button.

Insert the adjustment tool into the tool hole on the changer

mechanism. Then press the DISC+ button to move the

mechanism deck until the mechanism's slider hits the

adjustment tool. When the motor locks(stops) press the

REPEAT key of the H/U.

When the REPEAT key is pressed, the mechanism moves

automatically to the 1st stage and the initial position ad-

justment completes. (The data is written in the E2PROM

at this time.)

(W05-0635-01)