- 2 -

PN-2301M/U

If extended damage is caused due to negligence of re-

pair, the legal responsibility shall be with the repairing

company.

4. Caution in removal and making wiring connection to the

parts for the automobile.

Disconnect the battery terminal after turning the ignition

key off. If wrong wiring connections are made with the

battery connected, a short circuit and/or fire may occur.

If extensive damage is caused due to negligence of re-

pair, the legal responsibility shall be with the repairing

company.

5. Cautions regarding chips.

Do not reuse removed chips even when no abnormality

is observed in their appearance. Always replace them

with new ones. (The chip parts include resistors, capaci-

tors, diodes, transistors, etc). The negative pole of tanta-

lum capacitors is highly susceptible to heat, so use spe-

cial care when replacing them and check the operation

afterwards.

6. Cautions in handling flexible PWB

Before working with a soldering iron, make sure that the

iron tip temperature is around 270

. Take care not to

apply the iron tip repeatedly(more than three times)to the

same patterns. Also take care not to apply the tip with

force.

7. Turn the unit OFF during disassembly and parts replace-

ment. Recheck all work before you apply power to the

unit.

Chck the disc and replace it with a nondefective

disc.

8. Cautions in checking that the optical pickup lights up.

The laser is focused on the disc reflection surface through

the lens of the optical pickup. When checking that the

laser optical diode lights up, keep your eyes more than

30cms away from the lens. Prolonged viewing of the la-

ser within 30cms may damage your eyesight.

9. Cautions in handling the optical pickup

The laser diode of the optical pickup can be damaged by

electrostatic charge caused by your clothes and body.

Make sure to avoid electrostatic charges on your clothes

or body, or discharge static electricity before handling the

optical pickup.

9-1. Laser diode

The laser diode terminals are shorted for transpor-

tation in order to prevent electrostatic damage.

After replacement, open the shorted circuit. When

removing the pickup from the mechanism, short

the terminals by soldering them to prevent this

damage.

9-2. Actuator

The actuator has a powerful magnetic circuit. If a

magnetic material is put close to it. its characteris-

tics will change. Ensure that no foreign substances

enter through the ventilation slots in the cover.

9-3. Cleaning the lens

Dust on the optical lens affects performance. To

clean the lens, apply a small amount of isopropylalcohol

to lens paper and wipe the lens gently.

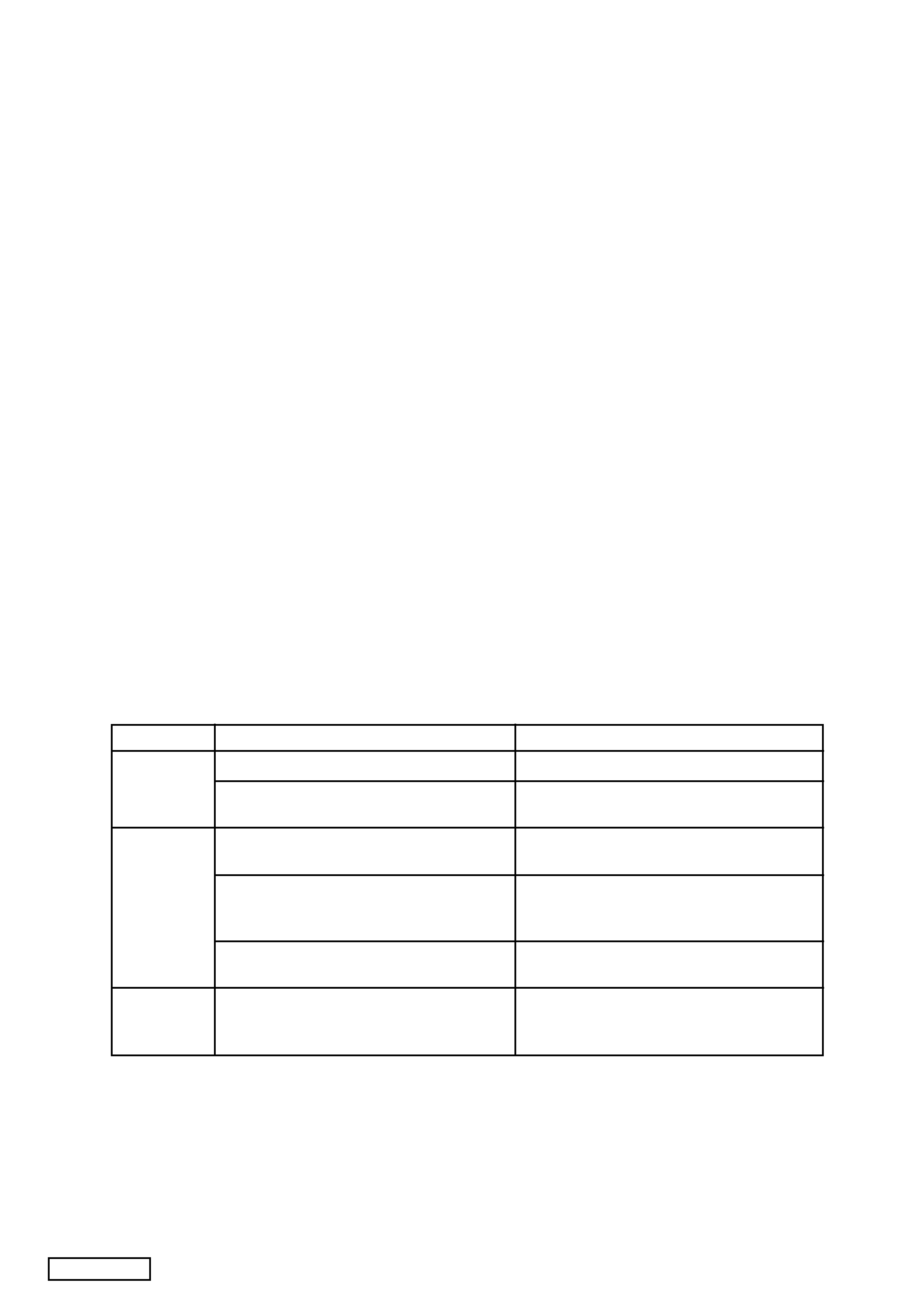

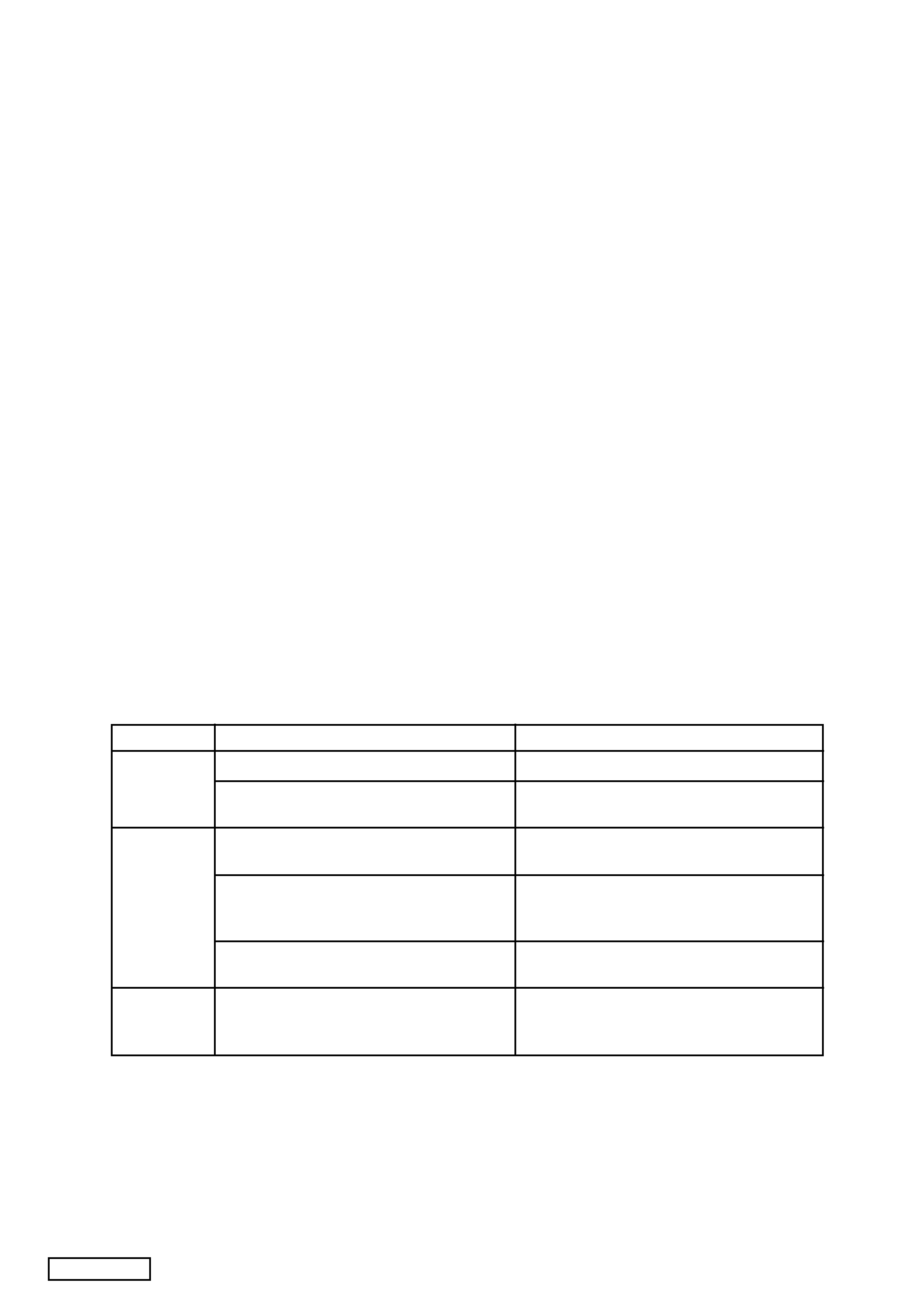

ERROR DISPLAYS

To protect the system,this unit has been equippedb with self diagnostic function.If a fault arises,a warning is issued by various error

displays.Follow the corrective measures and remove the fault.

Error Display

Err 1

Err 2

Err 3

Cause

The disc is dirty,warped or damaged,which pre-

vents the pickup from focuusing correctly.

Foreign matter in the disc insertion slot prevents

proper positioning of the disc.

All discs have been loaded upside down.

A disc was forced into the unit when the mes-

sage "WAIT" was displayed and loading can-

not be performed correctly.

The mechanism is damaged and disc cannot

be ejected or other symptoms are present.

The exterior of the disc is damaged and is de-

formed.

The disc is deformed.

Remedy

Eject the disc and load it with the correct side up.

Check the disc.

Remove foreign matter and eject the disc.

Turn on the power again.

If any other CDs are also loaded,eject all CDs.

The mechanism may have been damaged.