- 4 -

EN-1187B

pin 25: A

2

: IN : Address signal input.

pin 26: A

3

: IN : Address signal input.

pin 27: VDD

: - : Positive voltage supply.

pin 28: VSS

: - : Negative voltage supply.

pin 29: A

4

: IN : Address signal input.

pin 30: A

5

: IN : Address signal input.

pin 31: A

6

: IN : Address signal input.

pin 32: A

7

: IN : Address signal input.

pin 33: A

8

: IN : Address signal input.

pin 34: A

9

: IN : Address signal input.

pin 35: A 11

: IN : Address signal input.

pin 36: NU

: - : Not in use.

pin 37: CKE

: IN : Clock enable signal input.

pin 38: CLK

: IN : The clock pulse input.

pin 39: DQM

: IN : Makes data output Hi-Z, tSHZ after the

clock and masks the output. Blocks data

input when DQM active.

pin 40: NU

: - : Not in use.

pin 41: VSS

: - : Negative voltage supply.

pin 42: NU

: - : Not in use.

pin 43: VDD Q

: - : Positive power supply for the data I/O

ports.

pin 44: DQ 4

:I/O: The data input / output.

pin 45: NU

: - : Not in use.

pin 46: VSS Q

: - : Ground terminal for the data I/O ports.

pin 47: DQ 5

:I/O: The data input / output.

pin 48: NU

: - : Not in use.

pin 49: VDD Q

: - : Positive power supply for the data I/O

ports.

pin 50: DQ 6

:I/O: The data input / output.

pin 51: NU

: - : Not in use.

pin 52: VSS Q

: - : Ground terminal for the data I/O ports.

pin 53: DQ 7

:I/O: The data input / output.

pin 54: VSS

: - : Negative voltage supply.

051-6390-00

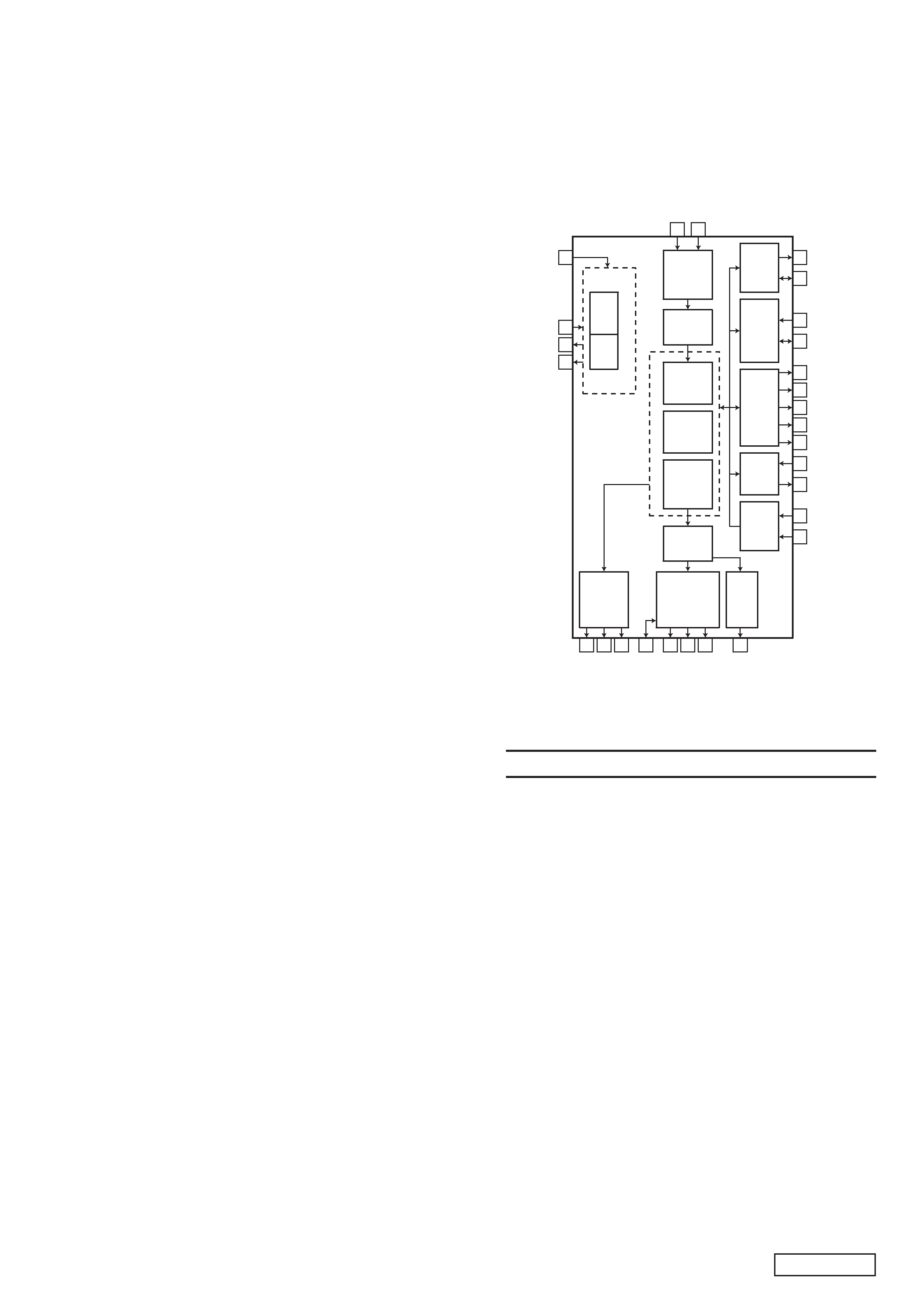

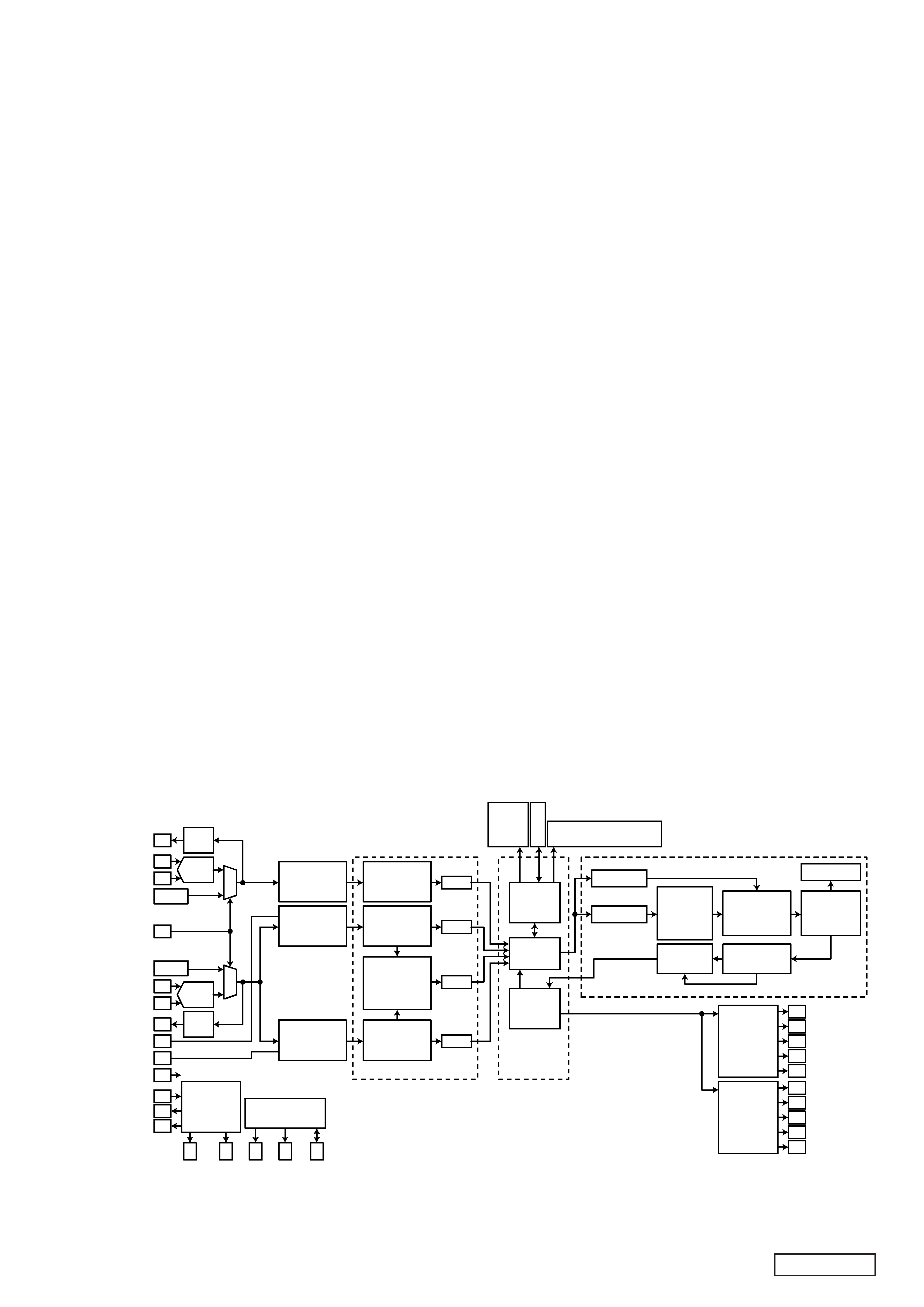

STA400

CHANNEL DECODER

DESCRIPTION

STA400 Channel Decoder integrates all the functions to demodulate and

decode the incoming satellite and terrestrial signals after the RF Front-

End down-convertion:

. Analog-to-Digital conversions

. Satellite and terrestrial demodulation

. AGC

. Frame synchronization and demultiplexing

. Viterbi decoding

. Time and spatial diversity combining

. Reed-Solomon decoding and deinterleaving

. Prime Rate Channel (PRC) demultiplexing

. Payload Channel (PC) selection

At the end of the demodulation and decoding processes a configurable

serial data stream is made available to STA450, the Service/Source

Decoder, via the PC Bitstream interface.

Terminal Description

pin

1: F TEST OUT 10: O : Configurable Functional Test Output

pin

2: F TEST OUT 11: O : Configurable Functional Test Output

pin

3: F TEST OUT 12: O : Configurable Functional Test Output

pin

4: F TEST OUT 13: O : Configurable Functional Test Output

pin

5: F TEST OUT 14: O : Configurable Functional Test Output

pin

6: F TEST OUT 15: O : Configurable Functional Test Output

pin

7: VDD

: - : 2.5V Positive Supply Voltage

pin

8: VDD 3

: - : 3.3V Positive Supply Voltage

pin

9: VSS

: - : Digital Ground

pin 10: Tref M

: - : Terrestrial ADC Reference Negative Volt-

age

pin 11: Tref P

: - : Terrestrial ADC Reference Positive Voltage

pin 12: T ADCref

: - : Analog terminal. Terrestrial ADC Reference

Adjust (external resistor to determine Ipol)

pin 13: T IN C M

: O : Analog output. Terrestrial ADC Internal

Common-Mode output for bypassing

pin 14: IF 2 TA P

: IN : Analog input. Terrestrial 2nd IF Differential

Input - Positive

pin 15: IF 2 TA N

: IN : Analog input. Terrestrial 2nd IF Differential

Input - Negative

pin 16: TV CMO

: - : Analog terminal. Terrestrial ADC Internal

Common Mode (filtered)

pin 17: A VDD

: - : 2.5V Analog Positive Supply Voltage

pin 18: A GND

: - : Analog Ground

pin 19: SV CMO

: - : Analog terminal. Satellite ADC Internal

Common Mode (filtered)

pin 20: IF 2 SA N

: IN : Analog input. Satellite 2nd IF Differential

Input - Negative

pin 21: IF 2 SA P

: IN : Analog input. Satellite 2nd IF Differential

Input - Positive

pin 22: S IN CM

: O : Analog output Satellite ADC Internal Com-

mon-Mode output for bypassing

pin 23: S ADCref

: - : Analog terminal. Satellite ADC Reference

Adjust (external resistor to determine Ipol)

pin 24: Sref P

: - : Satellite ADC Reference Positive Voltage

pin 25: Sref M

: - : Satellite ADC Reference Negative Voltage

pin 26: A VDD

: - : 2.5V Analog Positive Supply Voltage

pin 27: A GND

: - : Analog Ground

pin 28: M Reset

: IN : Master reset

pin 29: T AGC

: O : Terrestrial AGC Control Signal

pin 30: S AGC

: O : Satellite AGC Control Signal

pin 31: VSS

: - : Digital Ground

pin 32: XTO

: O : XTAL Output

pin 33: M CLK / XTI

: IN : XTAL Input or Master Clock Input

pin 34: ADC SEL

: IN : Selection between Internal or External ADC

0=Internal

pin 35: M CLK O

: O : Master Clock Output

pin 36: M CLK O N

: O : Inverted Master Clock Output

pin 37: LOCK S 1

: O : Satellite Dem1 Lock Indicator

pin 38: LOCK S 2

: O : Satellite Dem2 Lock Indicator

pin 39: VDD 3

: - : 3.3V Positive Supply Voltage

pin 40: VDD

: - : 2.5V Positive Supply Voltage

pin 41: VSS

: - : Digital Ground

pin 42: IF 2 TD 9

: IN : Terrestrial 2nd IF Digital Input

pin 43: IF 2 TD 8

: IN : Terrestrial 2nd IF Digital Input

pin 44: IF 2 TD 7

: IN : Terrestrial 2nd IF Digital Input

pin 45: IF 2 TD 6

: IN : Terrestrial 2nd IF Digital Input

pin 46: IF 2 TD 5

: IN : Terrestrial 2nd IF Digital Input

pin 47: IF 2 TD 4

: IN : Terrestrial 2nd IF Digital Input

pin 48: IF 2 TD 3

: IN : Terrestrial 2nd IF Digital Input

pin 49: IF 2 TD 2

: IN : Terrestrial 2nd IF Digital Input

pin 50: IF 2 TD 1

: IN : Terrestrial 2nd IF Digital Input

pin 51: IF 2 TD 0

: IN : Terrestrial 2nd IF Digital Input

pin 52: F TEST EN

: IN : Functional Test Enable (1=enable)

pin 53: INTR

: O : Interrupt

pin 54: VSS

: - : Digital Ground

pin 55: VDD

: - : 2.5V Positive Supply Voltage

pin 56: CLK D

: O : Divided Master Clock

pin 57: NC

: - : Not Connected. Reserved for Future Use.

pin 58: IF 2 SD 7

: IN : Satellite 2nd IF Digital Input

pin 59: IF 2 SD 6

: IN : Satellite 2nd IF Digital Input

pin 60: IF 2 SD 5

: IN : Satellite 2nd IF Digital Input

pin 61: IF 2 SD 4

: IN : Satellite 2nd IF Digital Input

pin 62: IF 2 SD 3

: IN : Satellite 2nd IF Digital Input

pin 63: IF 2 SD 2

: IN : Satellite 2nd IF Digital Input

pin 64: IF 2 SD 1

: IN : Satellite 2nd IF Digital Input

pin 65: IF 2 SD 0

: IN : Satellite 2nd IF Digital Input

pin 66: VDD 3

: - : 3.3V Positive Supply Voltage

pin 67: VDD

: - : 2.5V Positive Supply Voltage

pin 68: VSS

: - : Digital Ground

pin 69: S CL

: IN : IIC-bus Serial Clock

pin 70: S DA

:I/O: IIC-bus Serial Data

pin 71: TEST EN

: IN : ATPG Test Enable (1=Enabled)

pin 72: SCAN EN

: IN : Scan Enable (1=Enabled)

pin 73: BIST EN

: IN : RAM Bilt In Self Test Enable (1=Enabled)

pin 74: PC TS EF 2

: O : Payload Channel TSCC Synch2/Error Flag

2